Double container of synthetic resin by direct blow molding method

A synthetic resin and blow molding technology, applied in the field of double-layer containers, can solve the problems of expanding the diameter of the mouth cylinder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

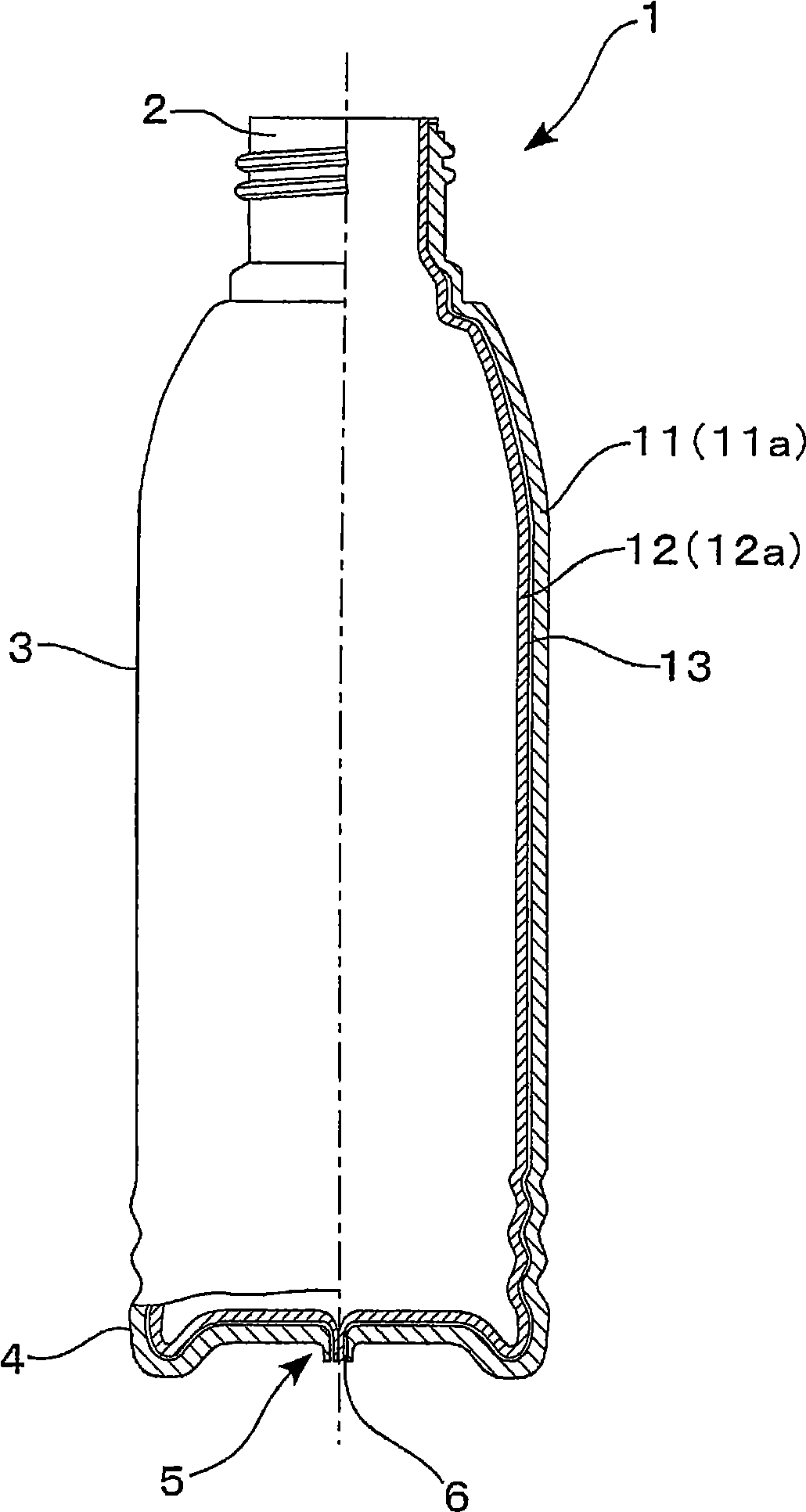

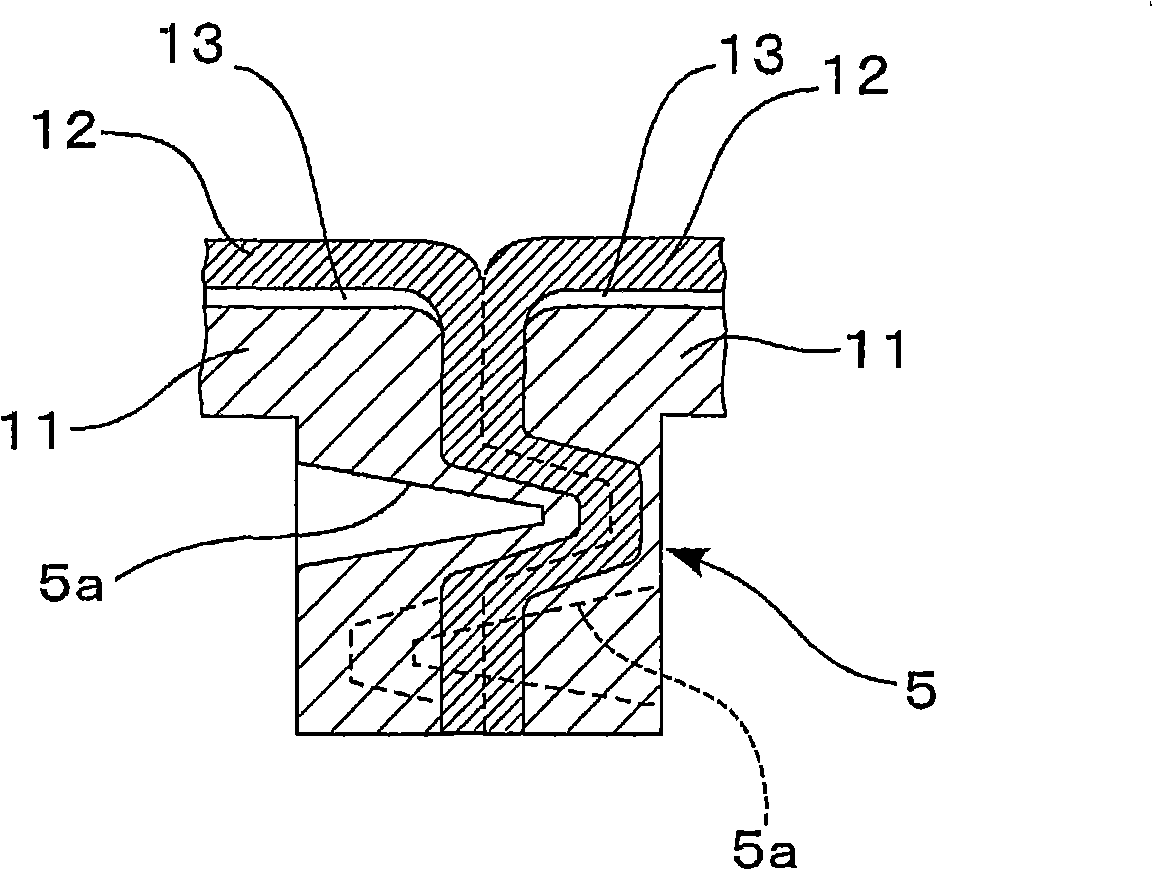

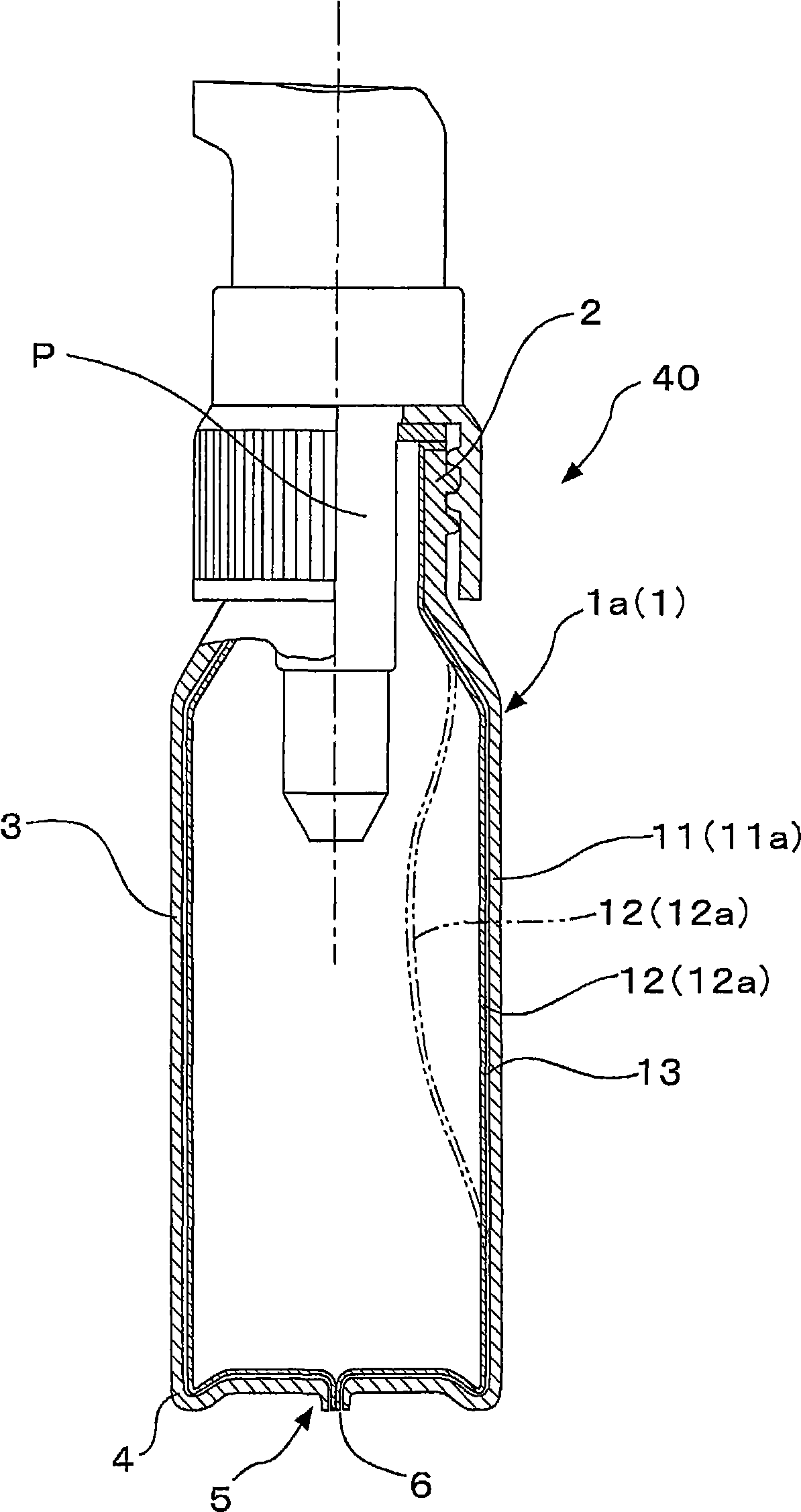

[0057] Hereinafter, embodiments of the present invention will be described based on examples and with reference to the drawings. figure 1 It is a partially vertically sectional front view showing the first embodiment of the double-walled container of the present invention. The double-layer container 1 is formed by direct blow molding, and is a bottle body having a mouthpiece 2 , a cylindrical body 3 and a bottom 4 .

[0058] This double-layer container 1 is composed of a container outer body 11a made of a polyethylene terephthalate (PET)-based resin outer layer 11 and a container inner body 12a made of a polypropylene (PP)-based resin inner layer 12. It is formed to have a double-walled structure that forms a gap 13 between the outer layer 11 and the inner layer 12 and sandwiches the gap 13 in the range from directly below the mouthpiece portion 2 to the bottle bottom 4 .

[0059] next to figure 1 The method for forming the double-layer container 1 will be described.

[006...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com