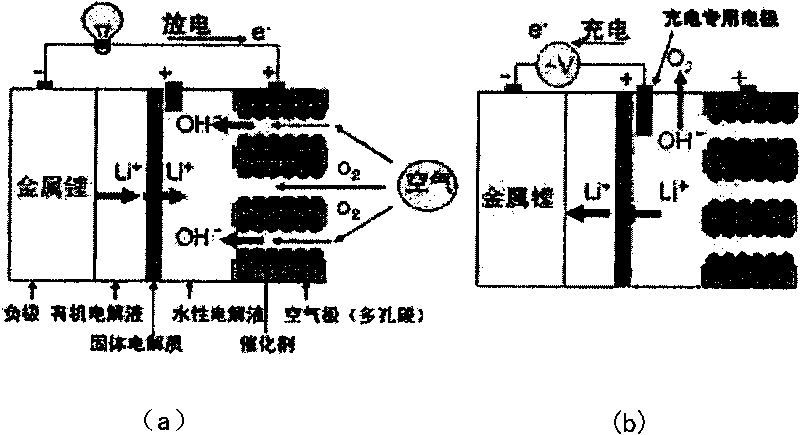

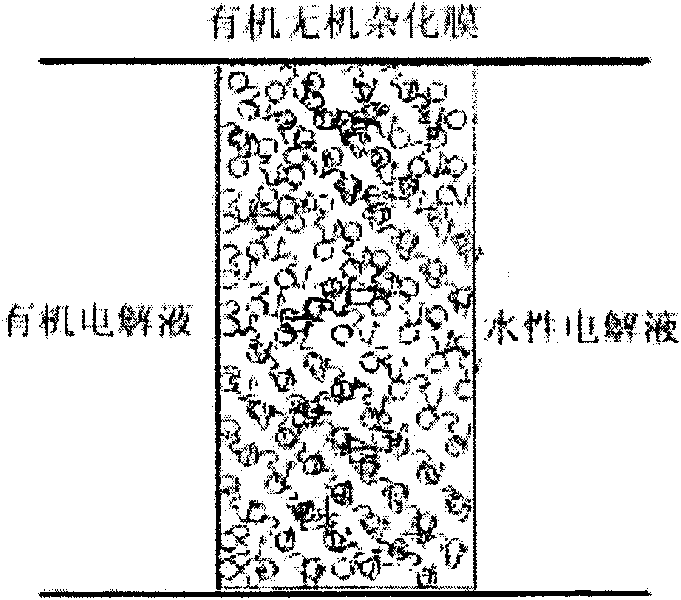

Diaphragm for lithium-air battery and preparation method thereof

A lithium-air battery and separator technology, applied in battery pack parts, circuits, electrical components, etc., can solve problems such as unsatisfactory performance, slow lithium ion passing, hindering the high performance of lithium-air batteries, and achieve good chemical stability. mechanical properties, the effect of avoiding contact with moisture and lithium metal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

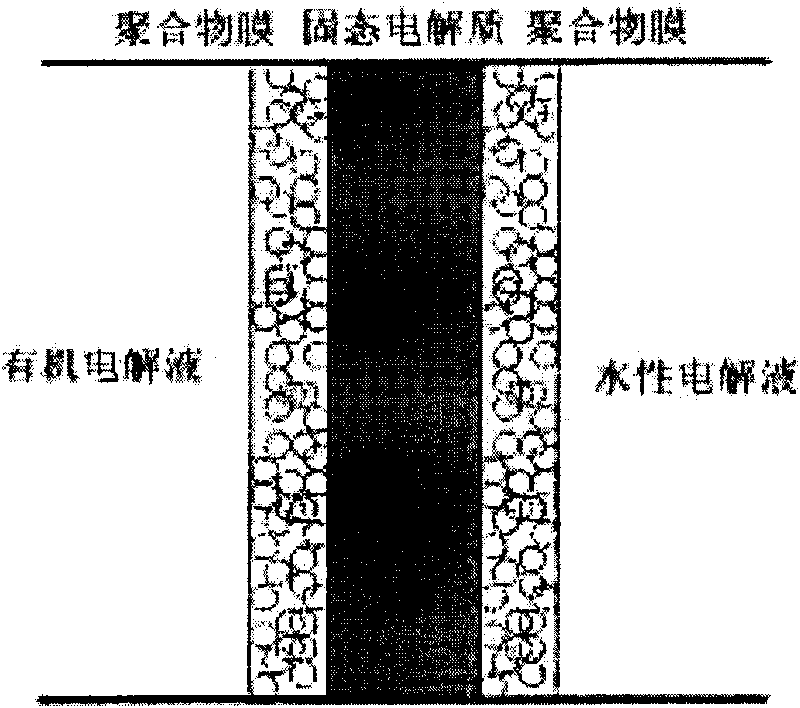

Embodiment 1

[0049] TiO 2 (7.99g), NH 4 h 2 PO 4 (11.5g) and LiH 2 PO 4 (5.2g) mixed well and ball milled for 5 hours (h), then in air atmosphere at 2°C min -1 Raise the temperature to 600°C at a certain rate, keep it warm for 24 hours, then raise the temperature of the sample to 1000°C, keep it warm for 48 hours, and after natural cooling, grind the product finely to obtain LiTi 2 (PO 4 ) 3 sample. place the sample in 10MPa / cm in the steel mold 2 The pressure is pressed into a disc with a thickness of 1mm, and the pressed sheet is sintered at 800°C for about 10h to obtain a composition of LiTi 2 (PO 4 ) 3 Solid lithium ion conductor.

[0050] Mix 0.70g of PVDF-HFP, 8.6mL of acetone, and 0.7mL of water, and stir in a magnetic stirrer at 70°C until completely dissolved. After dissolving, stir for another 15 minutes to obtain a clear and viscous sol, which is coated on one surface of the solid lithium ion conductor while still hot with a 600 μm spatula. After drying at room t...

Embodiment 2

[0052] NH 4 h 2 PO 4 At 100°C, Li 2 CO 3 , SiO 2 、Al 2 o 3 、TiO 2 and other components such as MgO at 200 ° C to constant weight, stored in a desiccator; according to NH 4 h 2 PO 4 (11.5g), Li 2 CO 3 (2.59g), SiO 2 (0.32g), Al 2 o 3 (0.255g), TiO 2 (7.2g), and MgO (0.28g), fully ground in an agate mortar and moved into a corundum crucible, placed the crucible containing the reactant in a high-temperature furnace and heated it at 170°C and 700°C for 4h respectively, and then heated it at 900°C ℃ heating for 20h to complete the reaction. place the sample in 10MPa / cm in the steel mold 2 The pressure is pressed into a disc, and the pressed sheet is sintered at 800 ° C for about 10 hours to obtain a composition of Li 1.4 Al 0.1 Mg 0.1 Ti 1.8 Si 0.1 P 2.9 o 12 The solid lithium ion conductor is then combined with the polymer film in Example 1 to prepare a three-layer sandwich structure.

Embodiment 3

[0054] La 2 o 3 (16.3g), Li 2 CO 3 (3.69g), TiO 2 (7.85g) is moved into corundum crucible after fully grinding in agate mortar, the crucible that reactant is housed is placed in high-temperature furnace and is kept at 800 ℃ in air atmosphere for 4 hours, and then is kept at 1350 ℃ for 12 hours. The obtained sample is ground finely, placed in a steel mold at 10MPa / cm 2 The pressure is pressed into a disc with a thickness of 1 mm and a diameter of 2 cm, and the pressed sheet is sintered at 1350 ° C for 6 hours and then cooled to room temperature to obtain a composition of Li 0.34 La 0.51 TiO 2.94 The inorganic lithium solid conductor is then compounded with the polymer film in Example 1 to prepare a three-layer sandwich structure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| ionic conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com