Method for preparing nitrogen-doped graphene with high nitrogen doping amount

A nitrogen-doped graphene and graphene technology, applied in the field of nitrogen-doped graphene, can solve the problems of low doping amount, harsh preparation conditions, and high production cost, and achieve low environmental pollution, simple reactant components, and production equipment. less effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

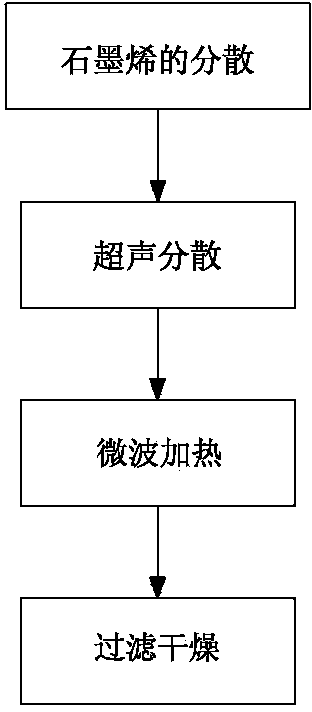

[0022] (1) Graphene dispersion: A graphene dispersion with a concentration of 1.0 mg / mL is prepared, the dispersant is multilayer graphene, and the dispersant is deionized water.

[0023] (2) Ultrasonic dispersion: The graphene dispersion and the nitrogen source are mixed at a certain mass ratio of 1:0.1, and after ultrasonic treatment for 2 hours, a mixture A is obtained. The nitrogen source is polypyrrole, polyaniline and polypyridine.

[0024] (3) Microwave heating: Move the mixture A into a 50mPa autoclave, then place the reactor in a microwave oven with a power of 2000w and heat it for 600s to obtain a mixture B.

[0025] (4) Filtration and drying: Filter the mixture B in a 0.2μm PTFE membrane filter, and the resulting filter cake is dried at a temperature of 80°C for 200 minutes to obtain nitrogen-doped graphene. The nitrogen doping amount is shown in Table 1. .

Embodiment 2

[0027] (1) Graphene dispersion: prepare a graphene dispersion with a concentration of 2.0 mg / mL, the dispersant is double-layer graphene, and the dispersant is dehydrated ethanol.

[0028] (2) Ultrasonic dispersion: The graphene dispersion and the nitrogen source are mixed at a certain mass ratio of 1:3, and after ultrasonic treatment is 0.5, the mixture A is obtained, and the nitrogen source is triethylenetetramine.

[0029] (3) Microwave heating: Move the mixture A into an autoclave with a pressure of 1 mPa, and then place the reactor in a microwave oven with a power of 1500 W and heat it for 10 seconds to obtain a mixture B.

[0030] (4) Filtration and drying: The mixture B is filtered in a 0.2μm PTFE membrane filter, and the resulting filter cake is dried at a temperature of 150°C for 20 minutes to obtain nitrogen-doped graphene. The nitrogen doping amount is shown in Table 1. .

Embodiment 3

[0032] (1) Graphene dispersion: prepare a graphene dispersion with a concentration of 3.0 mg / mL, the dispersant is multilayer graphene, and the dispersant is acetone.

[0033] (2) Ultrasonic dispersion: The graphene dispersion and the nitrogen source are mixed at a certain mass ratio of 1:10, and after ultrasonic treatment for 0.8 hours, a mixture A is obtained. The nitrogen source is melamine and dopamine.

[0034] (3) Microwave heating: Move the mixture A into an autoclave with a pressure of 5mPa, then place the reactor in a microwave oven with a power of 600w and heat it for 600s to obtain a mixture B.

[0035] (4) Filtration and drying: Filter the mixture B in a 0.2μm PTFE membrane filter, and the resulting filter cake is dried at a temperature of 100°C for 80 minutes to obtain nitrogen-doped graphene. The nitrogen doping amount is shown in Table 1. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com