Preparation method of carbon nano tube array/carbon fiber fabric integrated three-dimensional porous air electrode

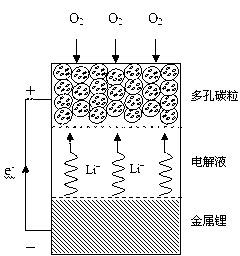

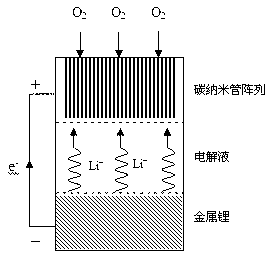

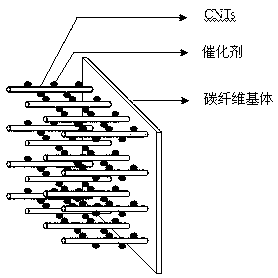

A technology of carbon nanotube arrays and carbon fiber fabrics, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of low energy conversion efficiency and power density, high electrode concentration polarization and ohmic polarization, mass transfer and load transfer Low capacity and other problems, to achieve the effect of excellent mechanical strength and chemical stability, high conductivity electron transport conductor, parallel channel structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The preparation method of the above-mentioned carbon nanotube array / carbon fiber fabric integrated air electrode includes the following four processes:

[0039] ⑴ Pretreatment of carbon fiber fabric

[0040] First, prepare the coating slurry on the surface of the carbon fiber fabric. Mix conductive carbon black with ammonium salt of oxidizing acid. The ammonium salt of oxidizing acid has strong oxidizing properties, and can oxidize the surface of conductive carbon black to produce a large number of hydrophilic groups such as hydroxyl, carbonyl and carboxyl on the surface. Group, easy to disperse into silica sol solution. In the inventive method, the ammonium salt of oxidizing acid comprises ammonium nitrate, ammonium sulfate, ammonium chlorate, ammonium persulfate, ammonium perborate and ammonium percarbonate, and the ammonium salt of conductive carbon black and oxidizing acid is by its mass ratio 1 : 0.01-2 mixed, the effect on the oxidation of conductive carbon blac...

Embodiment 1

[0050] Add 0.5g of conductive carbon black and 0.05g of ammonium persulfate into 100ml of deionized water, ultrasonically disperse for 1h, then mechanically stir at 25°C for 10h, then filter with suction and wash with distilled water for 5 times, and put the solid in a vacuum drying oven , dried at 80°C to constant weight. Add 0.5 g of modified carbon black and 5 g of ferric nitrate to 10 g of silica sol solution, and mechanically stir at room temperature for 36 hours to form a mixed solution. Remove the surface of the 3cm×4cm carbon fiber matrix, take the above mixed solution and spread it evenly on the carbon paper, let it dry after the first drop, continue to drop the second drop, repeat this way 5 times. Then put the carbon fiber matrix into the high-temperature tubular reactor, at a gas flow rate of 500cm 3 The temperature was raised to 800°C under the protection of argon gas per minute, kept for 1 h, and then lowered to room temperature under the protection of argon gas...

Embodiment 2

[0054] Add 0.5g of conductive carbon black and 0.1g of ammonium sulfate into 100ml of deionized water, ultrasonically disperse for 1.5h, then mechanically stir at 30°C for 15h, then filter with suction and wash with distilled water for 7 times, and put the solid in a vacuum drying oven , dried at 90°C to constant weight. Take the above 0.5g of modified carbon black and 3g of cobalt nitrate and add them into 15g of silica sol solution, and mechanically stir at room temperature for 24h to form a mixed solution. Remove the surface of the 3cm×4cm carbon fiber matrix, take the above mixed solution and spread it evenly on the carbon paper, let it dry after the first drop, continue to drop the second drop, and repeat this for 7 times. Then put the carbon fiber matrix into the high-temperature tubular reactor, at a gas flow rate of 500cm 3 The temperature was raised to 700°C under the protection of argon gas per minute, kept for 2 hours, and then lowered to room temperature under the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com