Method for synthetizing biological diesel oil by oil and fat materials

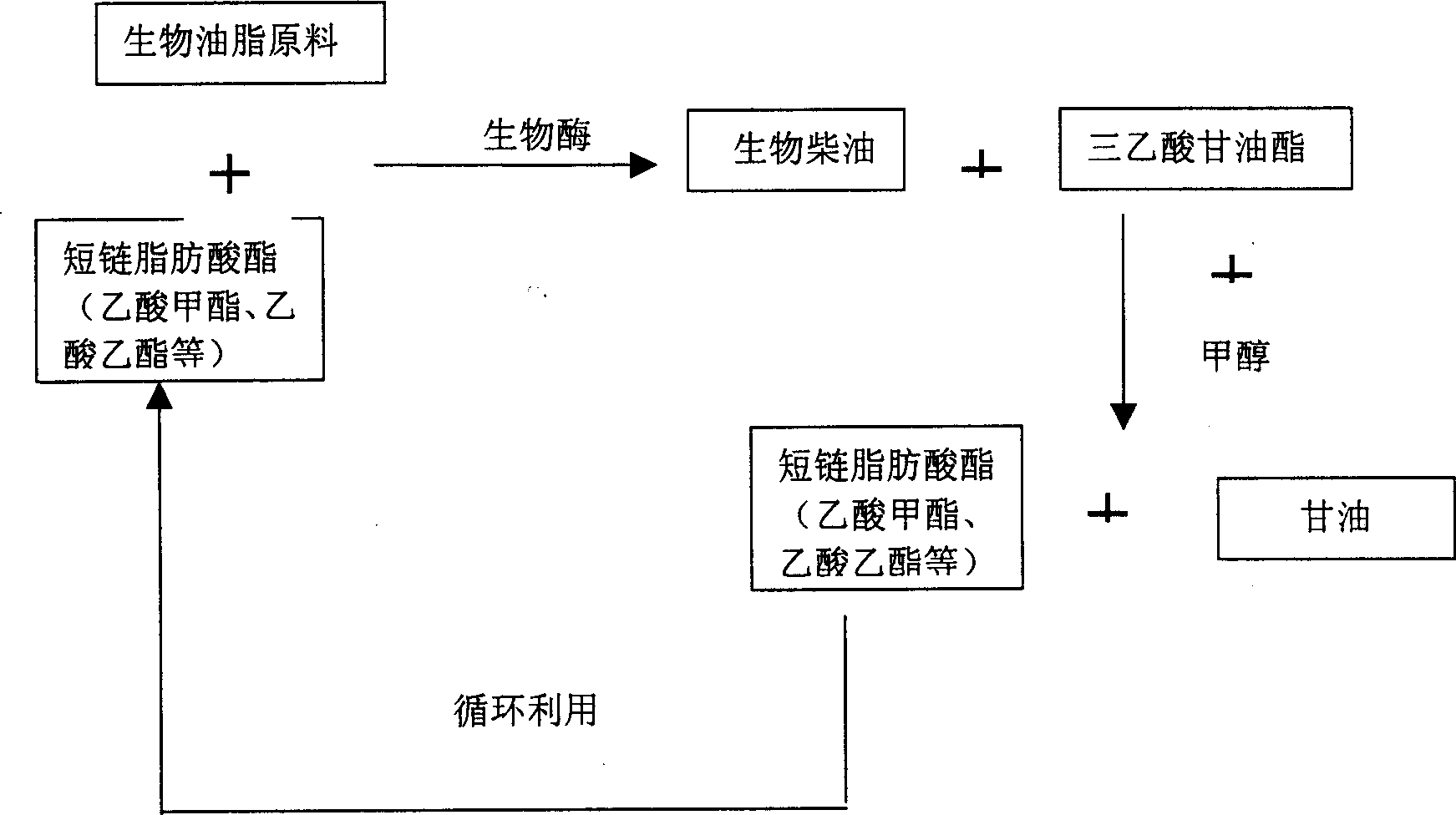

A technology for synthesizing biodiesel and biodiesel, which is applied in the preparation of liquid hydrocarbon mixtures, biological raw materials, and the petroleum industry. It can solve the problems of complex processing, affecting mass transfer, and poor solubility, and achieve high catalytic activity and reaction conditions. Mild, simple and easy-to-control reaction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0018] Example 1: Put 9.6g of methyl acetate and 9.65g of soybean oil into a stoppered Erlenmeyer flask, mix them evenly, place them in a reciprocating shaker with automatic temperature control and heat them to 40°C, then add 30% of the oil based on the quality of the oil The immobilized lipase Novozym 435 started to react, and 9.2 g of biodiesel was produced after 5-7 hours.

example 2

[0019] Example 2: Put 10 g of ethyl acetate and 9.65 g of soybean oil into a stoppered Erlenmeyer flask and mix them evenly, and place them in a reciprocating shaker with automatic temperature control and heat them to 40°C. The lipase Novozym 435 started to react, and 8.2g of biodiesel was produced after 10-14 hours.

example 3

[0020] Example 3: Put 9.6g of methyl acetate and 9.65g of rapeseed oil into a stoppered Erlenmeyer flask and mix them evenly, and place them in a reciprocating shaker with automatic temperature control and heat them to 40°C, then add 30% based on the quality of the oil The immobilized lipase Novozym 435 started to react, and 9.2 g of biodiesel was produced after 5-7 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com