Iron-nickel alloy/nickel ferrite magnetic composite nanofiber and preparation method thereof

A technology of magnetic composite nanometer and nickel ferrite, which is applied in fiber processing, spinning solution preparation, inorganic material magnetism, etc., to achieve the effects of high strength, widening absorption of electromagnetic waves, and easy control of the reaction process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

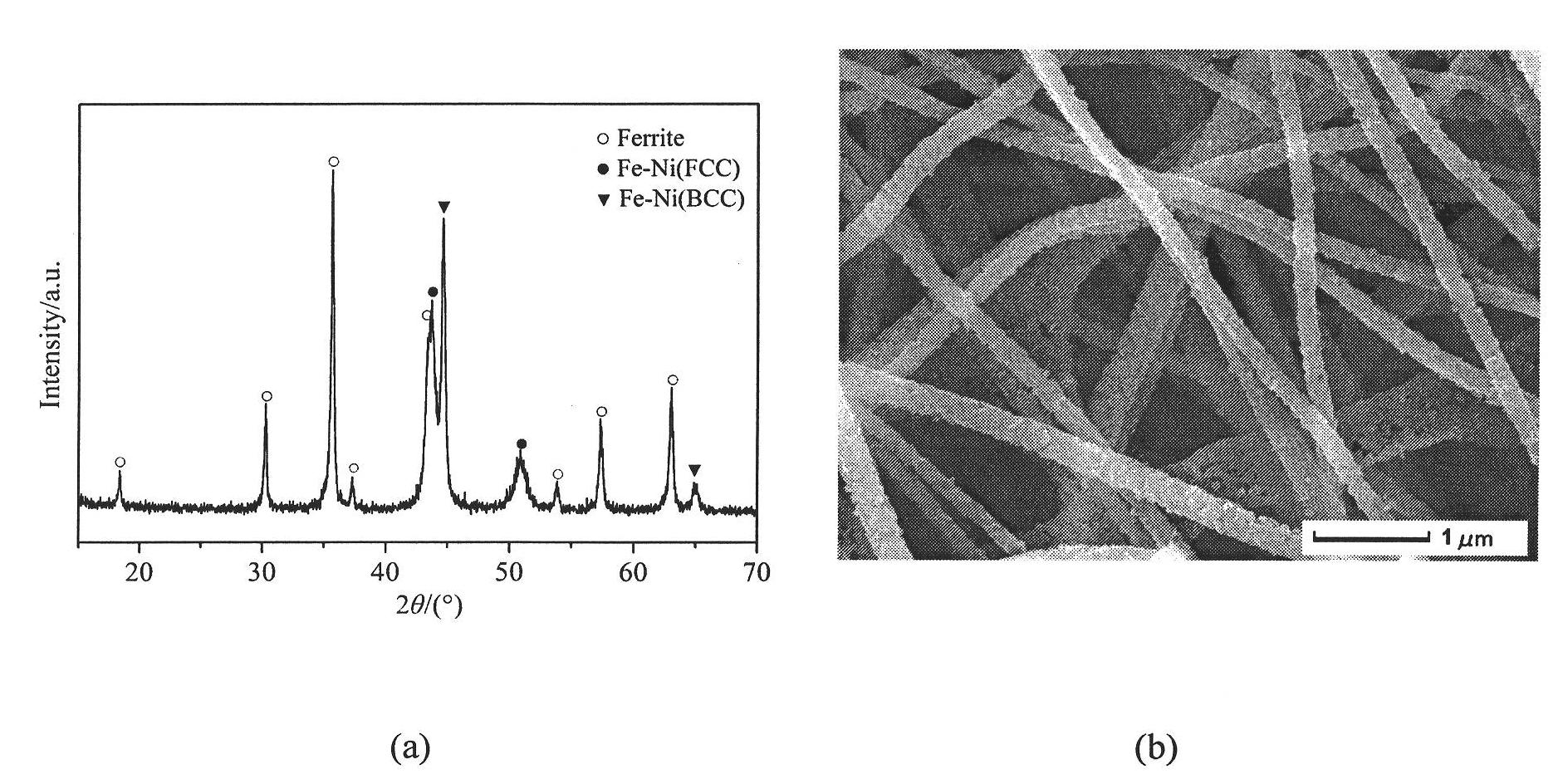

[0026] Example 1 (Ni / Fe=0.5 in the raw material, calcination at 550°C for 2h in air, reduction at 300°C in hydrogen for 1h)

[0027] Step 1: Add 0.5000g polyvinylpyrrolidone (PVP) to 4.5000g absolute ethanol (CH 3 CH 2 OH, analytically pure), the polymer was completely dissolved by magnetic stirring for about 1 hour, and then 0.7645 g of iron nitrate (Fe(NO 3 ) 3 9H 2 O, analytically pure), 0.2355g nickel acetate (Ni(CH 3 COO) 2 4H 2 O, analytically pure) and 2.0000g deionized water, and finally continue magnetic stirring for about 20 hours to form a uniform and stable precursor solution, wherein the concentration of PVP is 6.25wt%, and the concentration of metal salt is 12.5wt%.

[0028]Step 2: Transfer the obtained precursor solution to a plastic syringe with a stainless steel needle with an outer diameter of 0.8 mm. The stainless steel needle is connected to the positive pole of the high-voltage power supply, and the aluminum foil is used as a receiver to connect to t...

Embodiment 2

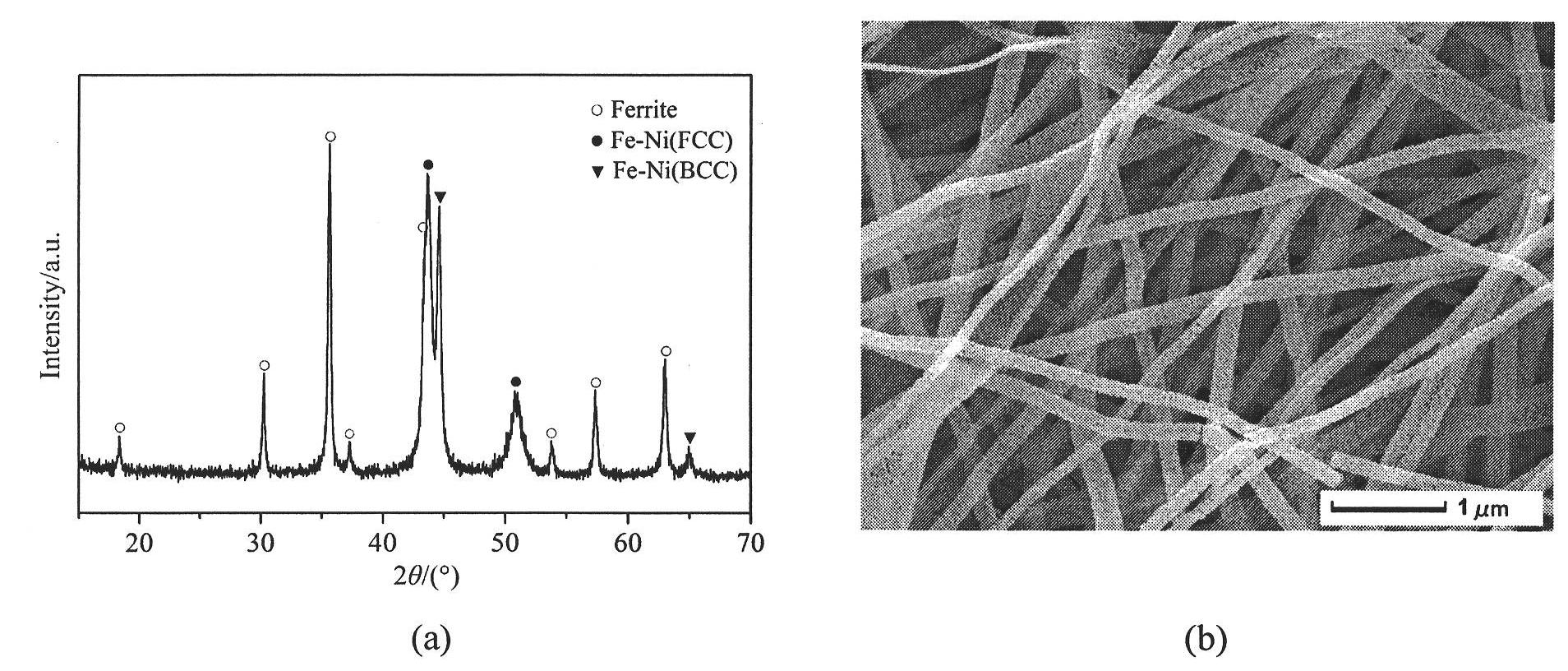

[0030] Example 2 (Ni / Fe=0.6 in the raw material, calcination at 550°C for 2h in air, reduction at 300°C in hydrogen for 1h)

[0031] Step 1: Add 0.5000g of PVP into 4.5000g of absolute ethanol, stir for about 1 hour to completely dissolve the polymer, then add 0.7285g of ferric nitrate, 0.2715g of nickel acetate and 2.0000g of deionized water, and finally continue magnetic stirring After about 20 hours, a uniform and stable precursor solution was formed, wherein the concentration of PVP was 6.25wt%, and the concentration of metal salt was 12.5wt%.

[0032] Step 2 is identical with embodiment 1 step 2;

[0033] Step 3 is the same as Step 3 of Example 1, and the diameter of the synthesized iron-nickel alloy / nickel ferrite composite nanofiber is about 140-190 nm.

Embodiment 3

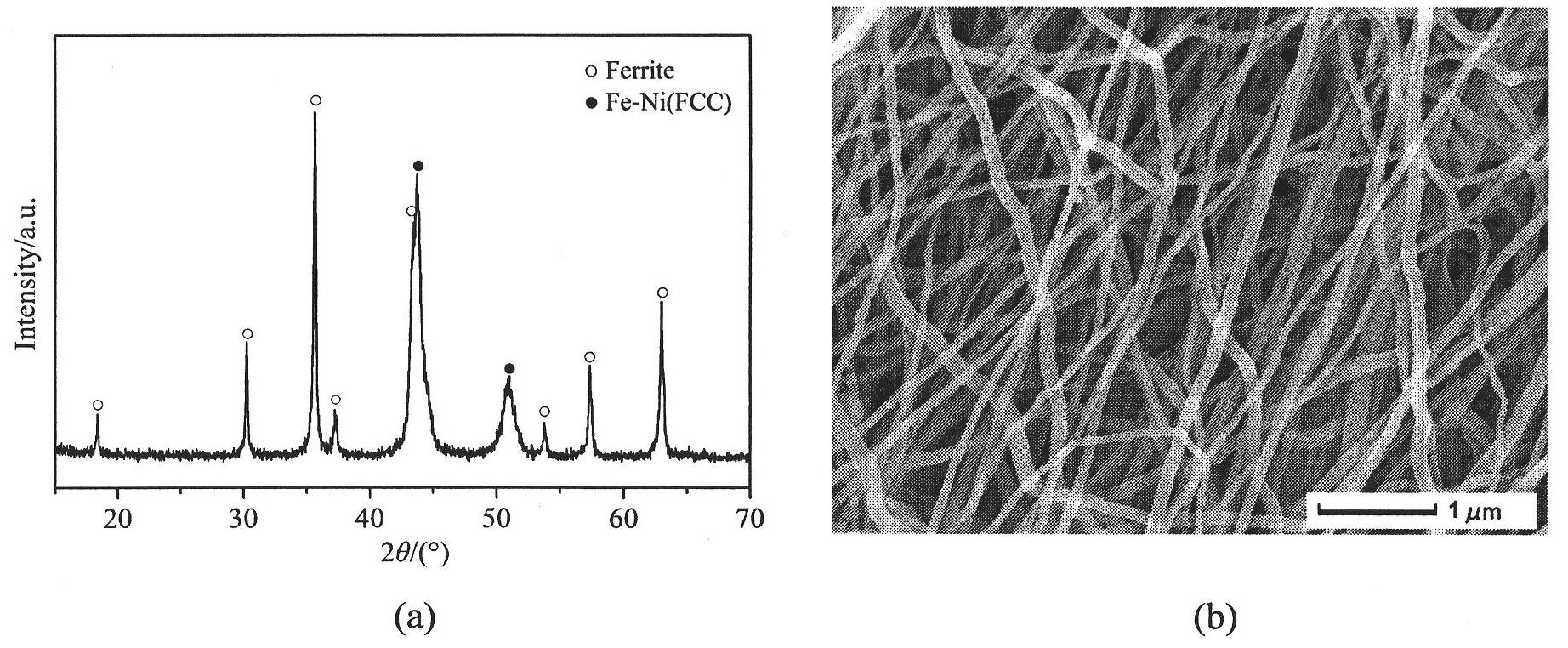

[0034] Example 3 (Ni / Fe=0.85 in the raw material, calcination at 550°C for 2h in air, reduction at 300°C in hydrogen for 1.5h)

[0035] Step 1: Add 0.5000g of PVP to 4.5000g of absolute ethanol, stir for about 1 hour to completely dissolve the polymer, then add 0.6557g of ferric nitrate, 0.3443g of nickel acetate and 2.0000g of deionized water, and finally continue magnetic stirring After about 20 hours, a uniform and stable precursor solution was formed, wherein the concentration of PVP was 6.25wt%, and the concentration of metal salt was 12.5wt%.

[0036] Step 2 is identical with embodiment 1 step 2;

[0037] Step 3 is basically the same as Step 3 of Example 1, but the reduction time in a hydrogen atmosphere is changed to 1.5 hours. The diameter of the synthesized iron-nickel alloy / nickel ferrite composite nanofiber is about 100-160nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dimension diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com