Li-Zn ferrite magnetic nanometer fiber and preparation method thereof

A magnetic nano and ferrite technology, applied in fiber processing, spinning solution preparation, fiber chemical characteristics, etc., can solve the problems of low cost and achieve low cost, high yield and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] (3) Preparation of Li-Zn ferrite nanofibers: the precursor fibers obtained in step (2) are properly dried in the range of 80-100°C and then put into a program-controlled electric furnace for heat treatment, at a temperature of 2-5°C / min The heating rate is heated from room temperature to 350-600°C, preferably 400-550°C, and kept at the calcination temperature for 1-3 hours, and then naturally cooled to room temperature with the furnace body, and the Li-Zn ferrite described in the present invention can be obtained. body nanofibers.

[0032] Said polymer of the present invention is polyvinylpyrrolidone, polyvinyl alcohol, polyacrylonitrile etc., preferably polyvinylpyrrolidone, average molecular weight is 1300000.

[0033] Said solvent of the present invention is water, ethanol or dimethylformamide etc., preferably ethanol or water.

Embodiment 1

[0035] Take 1.5000g polyvinylpyrrolidone (PVP, average molecular weight Mw=1300000) and add it to a mixed solvent composed of 15.6600g absolute ethanol and 10.4400g deionized water, stir magnetically at room temperature until the polymer is completely dissolved, and then weigh 2.1440g ferric nitrate, 0.0545g lithium nitrate and 0.2015g zinc nitrate are added together in the above-mentioned PVP solution, continue magnetic stirring for about 10 hours to form a homogeneous, transparent and stable spinning solution, wherein the mass percentage of PVP is 5wt%, and the mass percentage of inorganic salt is 8wt%.

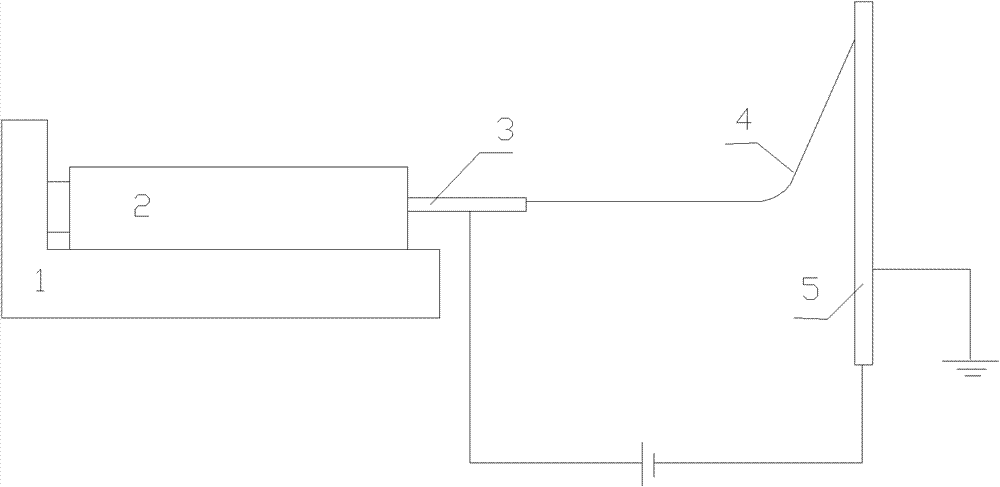

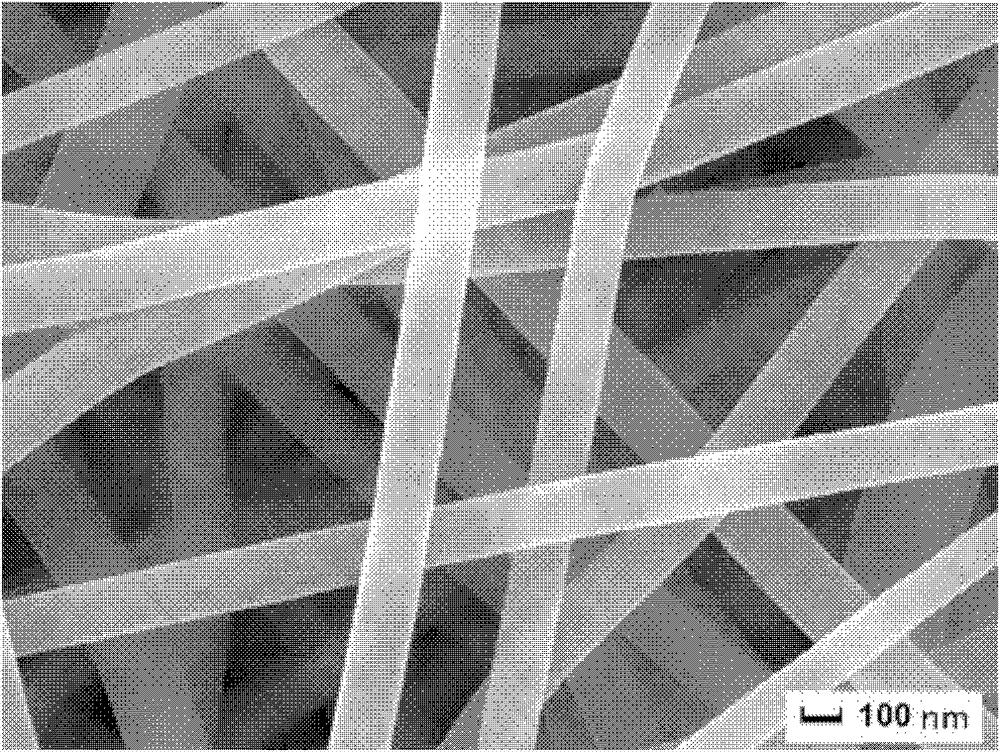

[0036] Introduce the obtained spinning solution into the electrospinning device, and then apply a voltage of 15kV, the solution feed rate is 0.5mL / h, the receiving distance is 15cm, the temperature is 20-25°C, and the humidity is 40-50%. Carry out electrospinning, the morphology of the PVP / inorganic salt composite precursor fiber that makes is shown in figure 2 As shown, ...

Embodiment 2

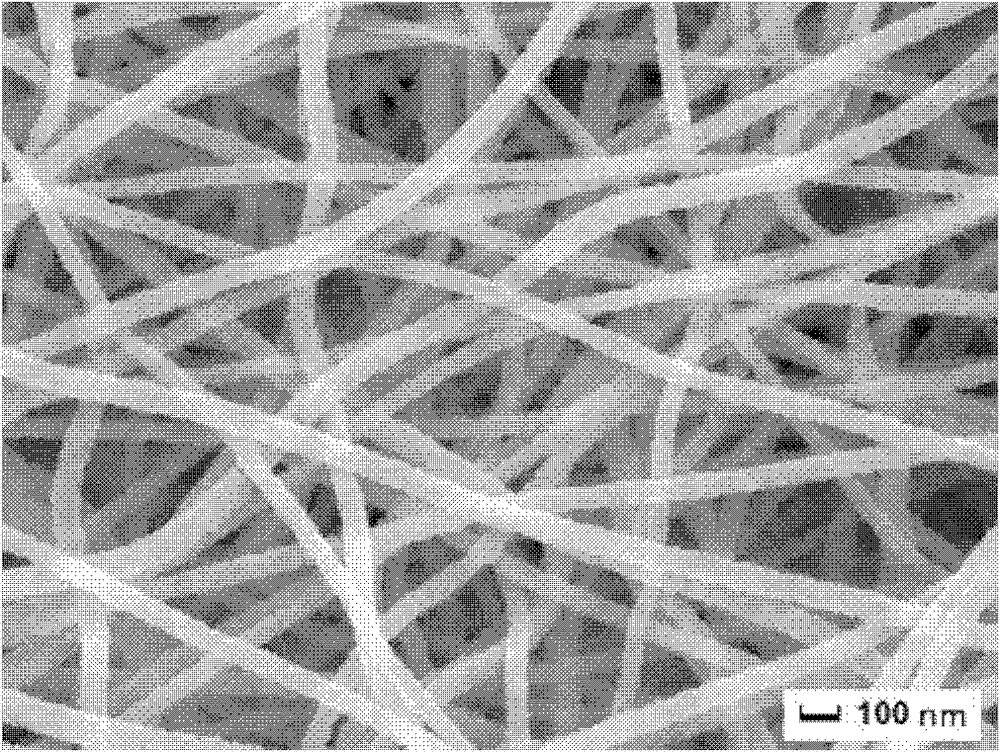

[0039] The basic preparation process is the same as that of Example 1, except that the chemical composition of the inorganic salt is the ratio of the amount of metal elements: the masses of iron nitrate, lithium nitrate and zinc nitrate are 2.2022, 0.0626 and 0.1351 g, respectively. Li produced 0.4 Zn 0.2 Fe 2.4 o 4 The diameter of the nanofiber is 50-100nm, with a single-phase cubic spinel structure, and the specific saturation magnetization and coercive force at room temperature are 67.8A m 2 kg -1 and 14.5kA·m -1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com