Oxydol etching solution for copper-molybdenum alloy films

A technology of copper-molybdenum alloy film and etching solution, which is applied in the field of etching solution, can solve the problems of high risk for operators and client equipment, difficulty in controlling the etching angle and etching time, unfriendly environment of fluoride, etc., and achieve the etching cone angle Suitable, easy to control the reaction, and small CD loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

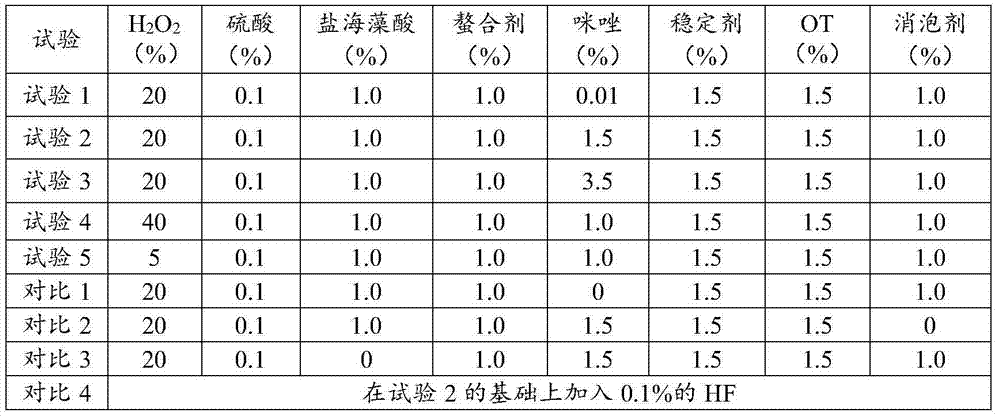

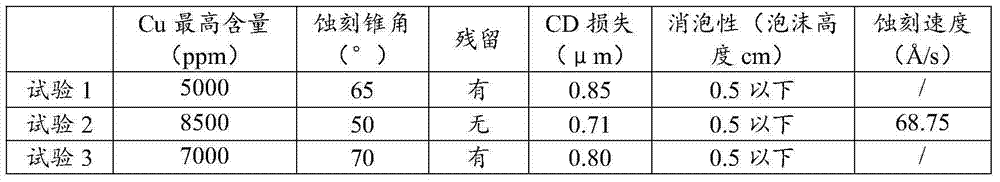

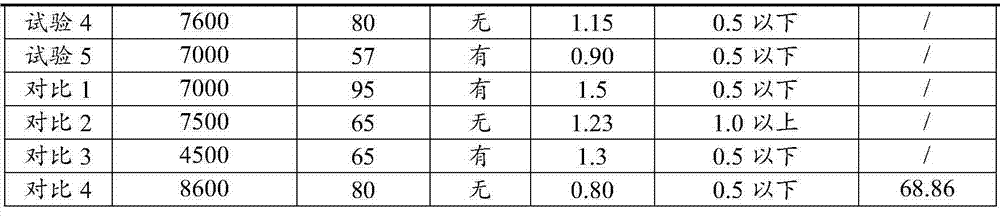

[0022] The etching solution in this example is composed of hydrogen peroxide, inorganic acid, hydrogen peroxide stabilizer, metal chelating agent, etching additive, surfactant, defoamer and deionized water. In this example, sulfuric acid is used as the inorganic acid; polyacrylic acid amine is used as the hydrogen peroxide stabilizer; glycolic acid is used as the metal chelating agent; and the etching additive is composed of nitrogen-containing heterocyclic compounds and salts. Specifically, imidazole is used for nitrogen-containing heterocyclic compounds. , the salt is sodium alginate; the surfactant is OT surfactant purchased from the market; the defoamer is NP-5 purchased from the market, that is, nonylphenol polyoxyethylene 5 ether. In this example, the dosages of the above components were tested respectively, and four comparative tests were set up, see Table 1 for details, and each percentage in Table 1 is a percentage by weight, that is, the percentage of the component in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com