Method for hydrophilic modifying of poly-vinylidene fluoride film

A hydrophilic modification and hydrophilic technology, applied in the field of polymer film preparation, can solve the problems of poor graft modification effect, high chemical bond energy, low surface energy, etc., achieve good anti-pollution performance, improve hydrophilicity The effect of improving the property and hydrophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

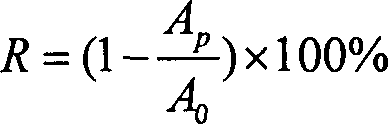

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The photosensitive group-containing polymer used in this embodiment is polyethersulfone (PES). Mix PVDF, PES and N-methylpyrrolidone uniformly in a mass ratio of 14.5:0.5:85, then add LiCl of 3 / 10 of the total amount of the polymer, stir well, and prepare a casting solution. Mature at 60-70°C for 24 hours, and let stand for defoaming. The casting liquid is poured on the non-woven fabric, and the water is used as the coagulation bath, and the flat filter membrane is prepared by the phase inversion method. The film thickness is about 200 μm, and the rejection rate of 0.1% BSA solution is 76.4%. Surface graft polymerization was carried out in a tetrafluoroethylene circular reactor with a diameter of 5 cm. The membrane was installed face up in the reactor, and then the monomer solution was added to a height of about 5 mm on the surface of the membrane. The reactor is placed directly below the straight ultraviolet lamp source, and the power of the ultraviolet lamp is 500W...

Embodiment 2

[0030] The flat filter membrane prepared in Example 1 was used for graft modification under the same irradiation conditions.

[0031] The hydrophilic monomer used was N-vinyl-2-pyrrolidone (NVP), the concentration of the aqueous monomer solution was 3%, and the grafting time was 10 minutes. After the reaction, the film was dried in a vacuum oven. The contact angle of the modified membrane was measured to be 33°, the fouling coefficient m of the membrane was 0.280, the pure water flux recovery coefficient γ of the membrane was 96.5%, and the rejection rate of the modified membrane to 0.1% BSA solution was 78.5%.

Embodiment 3

[0033]The polymer with photosensitive groups used in this embodiment is phenolphthalein-based polyethersulfone (PES-C). Mix PVDF, PES-C and N-methylpyrrolidone uniformly in a mass ratio of 13.3:0.7:86, then add LiCl of 3 / 10 of the total amount of the polymer, stir well, and prepare a casting solution at 60- Mature at 70°C for 24 hours, and let stand for defoaming. The casting liquid is poured on the non-woven fabric, and the water is used as the coagulation bath, and the flat filter membrane is prepared by the phase inversion method. The film thickness is about 200 μm, and the rejection rate of 0.1% BSA solution is 72.4%. The irradiation method is the same as in Example 1. The height of adding the monomer solution is about 7mm. The power of the used straight ultraviolet lamp is 1000W. The distance between the reactor and the ultraviolet light source is 20 cm.

[0034] The hydrophilic monomer used in this example is 2-acrylamido-2-methyl-propanesulfonic acid (AMPS), the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com