Preparation method for yolk-eggshell-type organic-inorganic hybrid silicon oxide nanosphere

A technology of eggshell type and silicon oxide, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve complex process, difficult composition adjustment, and poor universal application and other problems, to achieve the effect of short time consumption, few steps and high storage capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

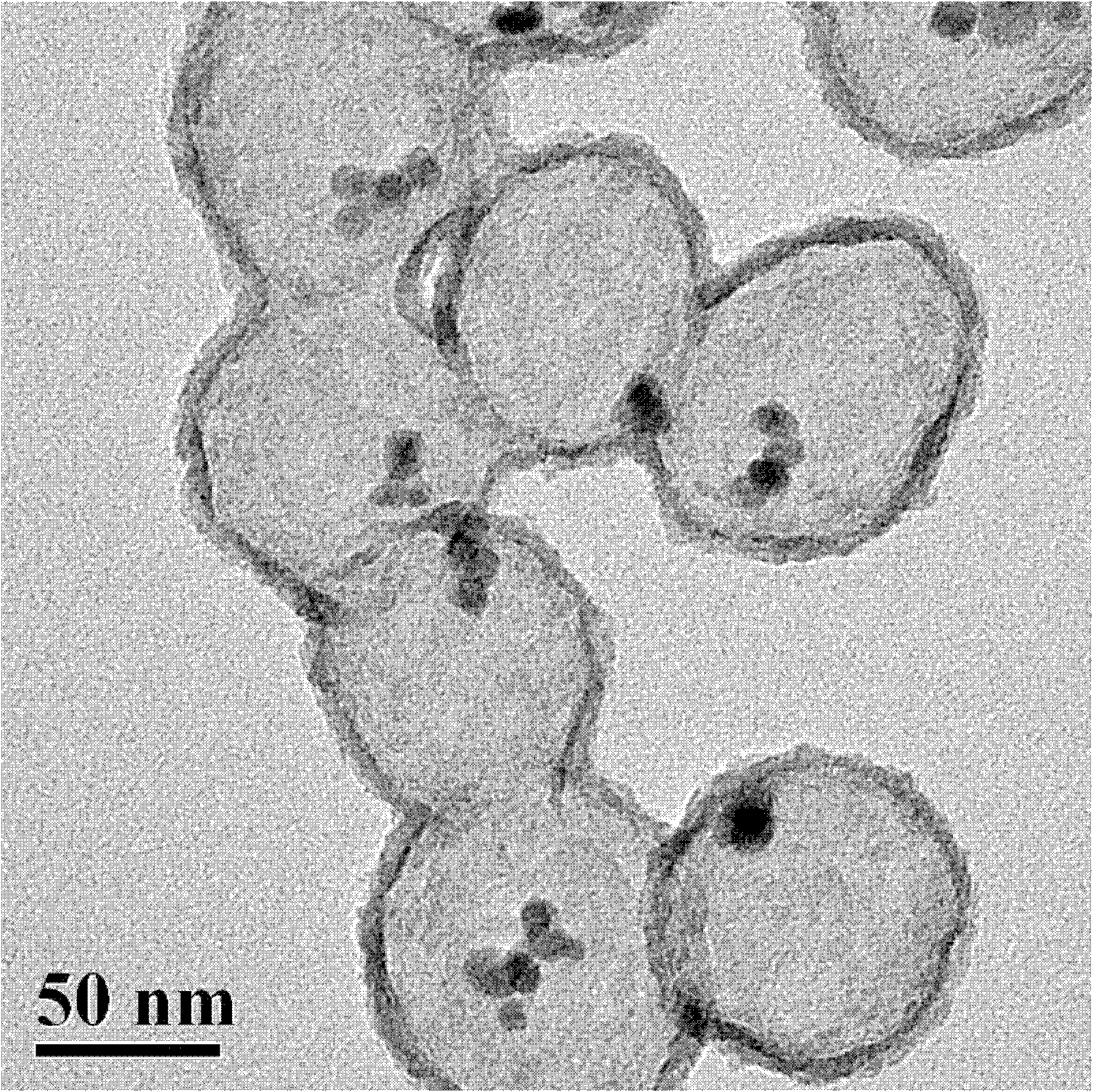

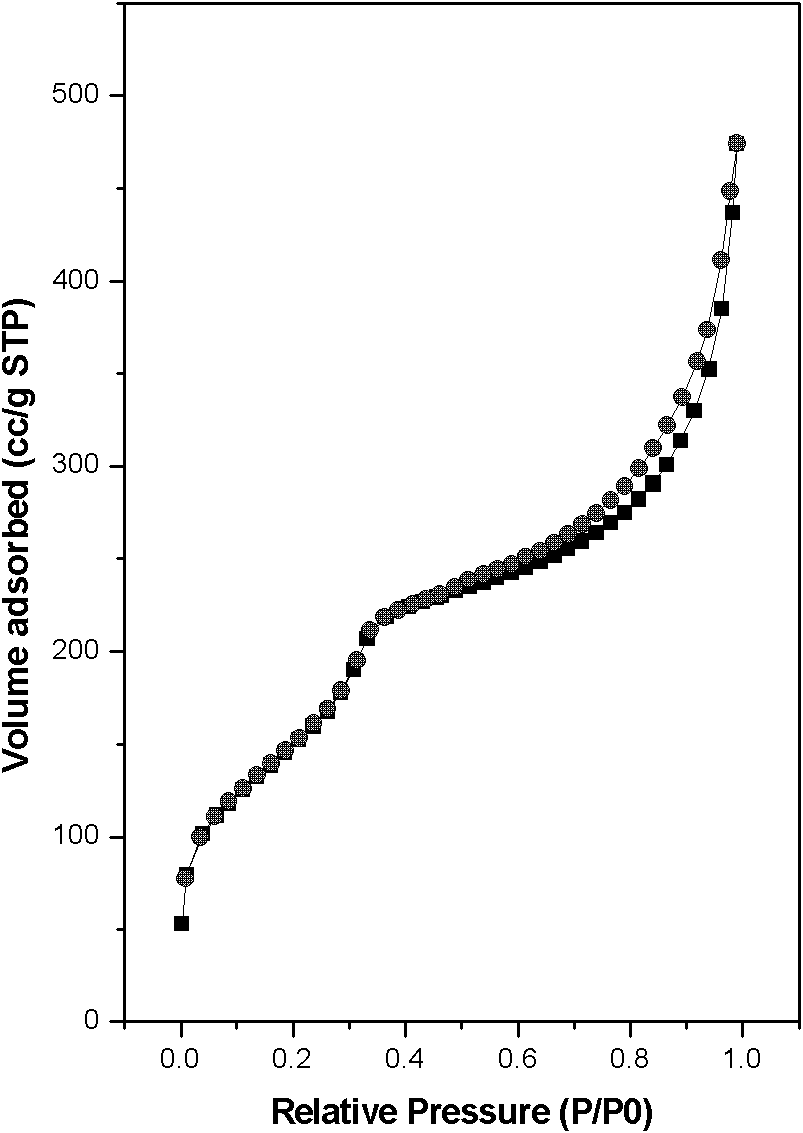

[0039] Under stirring at room temperature, dissolve 0.1 g CTAB in 10 mL deionized water, add 1 mL (10 mg mL -1 ) oleic acid-stabilized Fe dissolved in chloroform 3 o 4 Nanoparticle solution (Journal of Materials Chemistry2009, Vol. 19, No. 1811-1815), stirred for 0.5 h to form a uniform O / W emulsion, and heated to 60 o C. Chloroform was evaporated under stirring conditions to form a brown transparent solution, and 38 mL of water and 0.35 mL of NaOH (2 M) were added in sequence, and the temperature was raised to 80 oC , add 0.68 mL of TEOS, a few minutes later precipitation appeared, at 80 o Stir at C for 2 h, add 60 mL of water, add 0.36 mL of BTME (dissolved in 2 mL of ethanol) after the temperature is stable, and continue at 80 oC Stir for 1 h. After the product was filtered, washed with water and dried, it was dissolved in absolute ethanol solution with ammonium nitrate at 60 o C and stirred for 0.5 h, the product was filtered, washed with water, and dried to obtain ...

Embodiment 2

[0042] The preparation process of Example 1 was adopted, except that BTEB was added as a silicon source, and the stirring time was 3 h. A light brown-yellow powder was obtained. The representation method is the same as above. The TEM result shows that the obtained product is a nanoparticle with egg yolk-eggshell type, uniform particle size and good dispersion; the overall size of the eggyolk-eggshell type nanoparticle is 100 nm, and the wall thickness is 10nm ( image 3 ).

[0043]

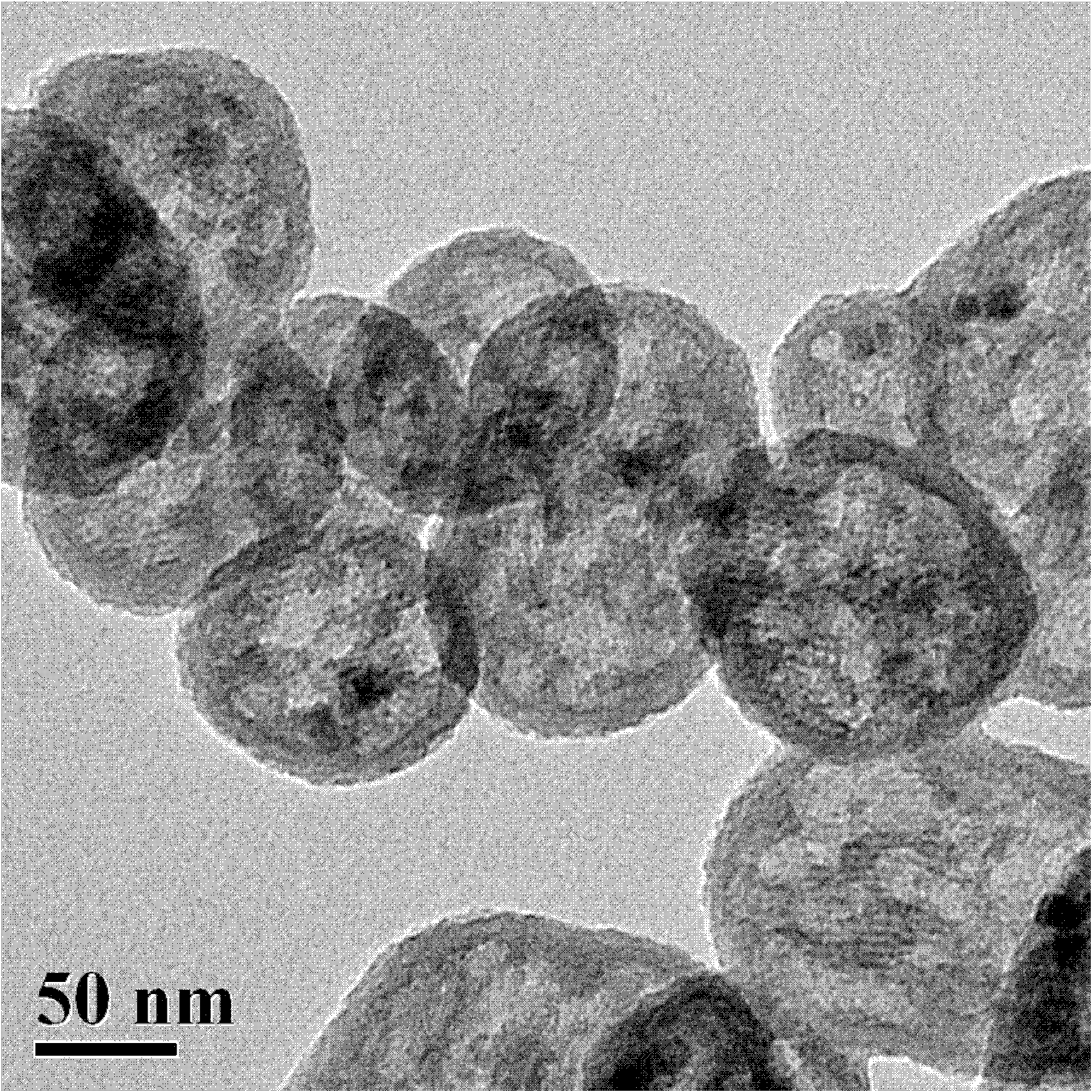

Embodiment 3

[0045] The preparation process of Example 1 was adopted, except that APTES was added as a silicon source, and the stirring time was 5 h. A light brown-yellow powder was obtained. The representation method is the same as above. TEM results show that the obtained product is a nanoparticle with egg yolk-eggshell type, with uniform particle size and good dispersion; the overall size of the egg yolk-eggshell type nanoparticle is 120 nm, and the wall thickness is 13 nm ( Figure 4 ).

[0046]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com