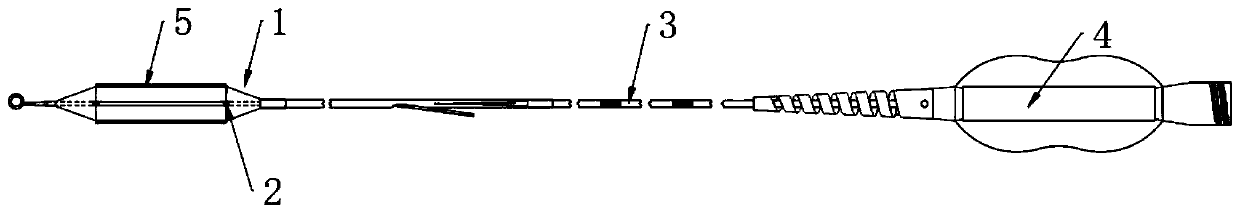

Medicine coating balloon, preparation method and medicine coating balloon dilatation catheter

A technology for drug coating and dilating catheters, applied in balloon catheters, catheters, coatings, etc., can solve the problems of drug balloon inhibition of restenosis and short drug release cycle, and achieve long-term restenosis and drug loss. Fewer and smaller gaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

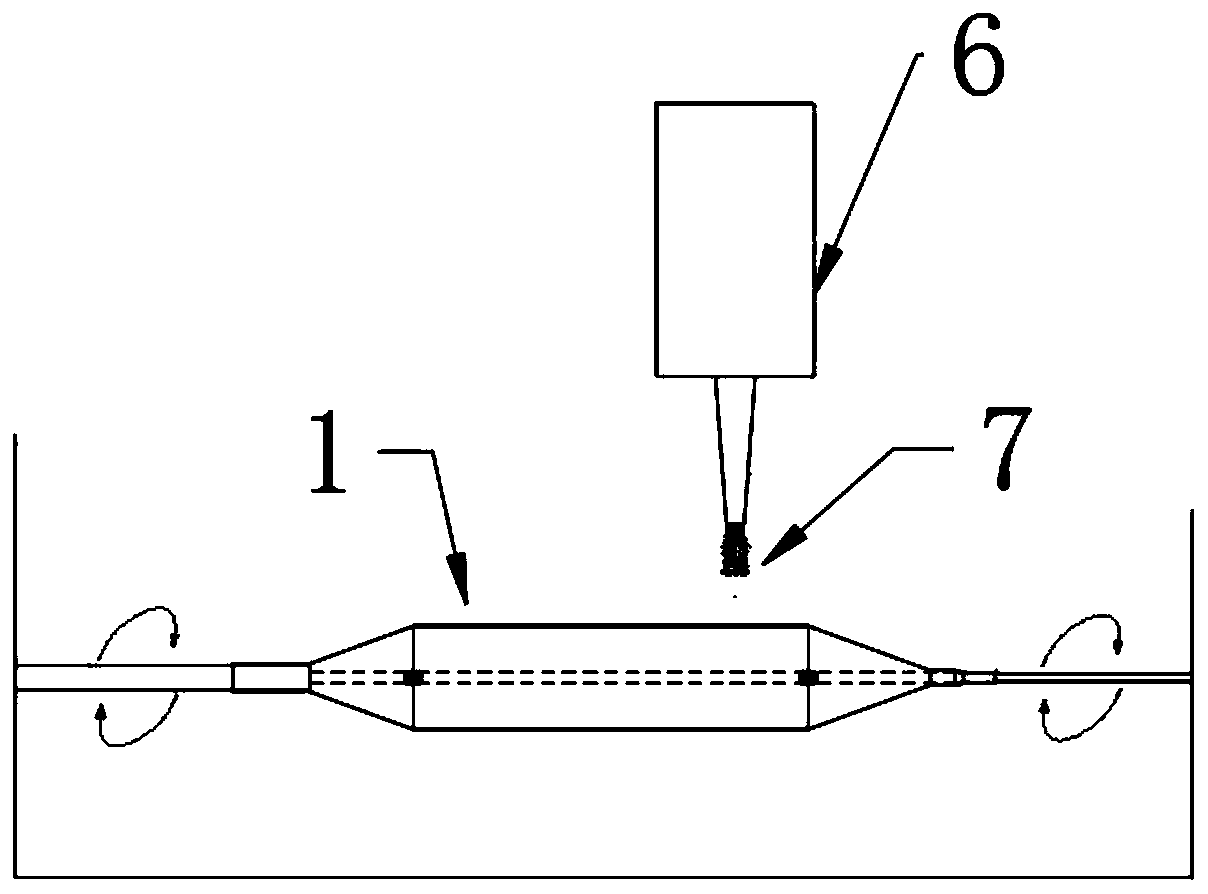

[0063] A method for producing a drug-coated balloon, comprising the steps of:

[0064] 1) Dissolve paclitaxel, iopromide and lecithin in acetone and water, ultrasonically dissolve until colorless and transparent, and filter to obtain a spray solution. The volume ratio of acetone to water is 9:1, the mass ratio of iopromide to lecithin is 5:1, the mass ratio of paclitaxel to excipients is 5:2, and the drug concentration is 12.5mg / ml.

[0065] 2) Spray the drug solution on the surface of the bare balloon, wherein the ultrasonic power is 1.0W, the flow rate of the drug solution delivered by the syringe pump is 0.1ml / min, the spray temperature is 30°C, the spray pressure is 0.05MPa, and the spray height is 50mm; spray 20 layers.

[0066] 3) Put the sprayed balloon in a vacuum drying oven and treat it at a constant temperature for 5 hours, wherein the temperature is 40°C.

Embodiment 2

[0068] A method for producing a drug-coated balloon, comprising the steps of:

[0069] 1) Dissolve paclitaxel, iopromide, and acetyl tributyl citrate in methanol, ultrasonically dissolve until colorless and transparent, and filter to obtain a spray solution. The mass ratio of iopromide to acetyl tributyl citrate is 8:1, the mass ratio of paclitaxel to excipients is 5:1, and the drug concentration is 20 mg / ml.

[0070] 2) Spray the drug solution on the surface of the bare balloon, wherein the ultrasonic power is 1.8W, the flow rate of the drug solution delivered by the syringe pump is 0.2ml / min, the spray temperature is 30°C, the spray pressure is 0.04MPa, and the spray height is 30mm; spray 15 layers.

[0071] 3) Put the sprayed balloon into a vacuum drying oven and treat it at a constant temperature for 3 hours, wherein the temperature is 40°C.

Embodiment 3

[0073] A method for preparing a drug-coated balloon, comprising the steps of:

[0074] 1) Dissolve paclitaxel, iohexol, and ethyl cellulose in methanol, ultrasonically dissolve until colorless and transparent, and filter to obtain a spray solution. The mass ratio of iohexol to ethyl cellulose is 2:1, the mass ratio of paclitaxel to excipients is 3:1, and the drug concentration is 15 mg / ml.

[0075] 2) Spray the drug solution on the surface of the bare balloon, wherein the ultrasonic power is 1.5W, the flow rate of the drug solution delivered by the syringe pump is 0.2ml / min, the spray temperature is 40°C, the spray pressure is 0.04MPa, and the spray height is 50mm; spray 15 layers.

[0076] 3) The sprayed balloon is placed in a vacuum drying oven, and treated at a constant temperature for 3 hours, wherein the temperature is 40°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com