Hydrophobic under-coating paint for polyolefin film and preparation method of hydrophobic under-coating paint

A polyolefin and film technology, applied in the coating and other directions, can solve the problems of not cheap price, high price of oily products, unsuitable for environmental protection requirements, etc., to achieve the effect of enhancing printing adaptability, low cost, and enhancing spreadability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

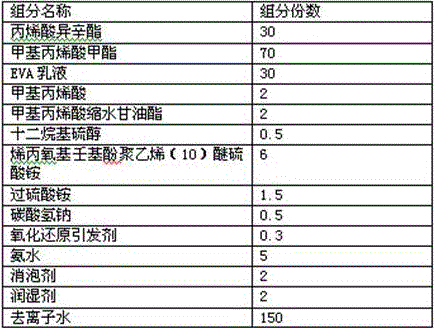

[0034] 1. Formula

[0035]

[0036] 2. Preparation method

[0037] (1) Preparation of pre-emulsion: According to the above formula, 30 parts of isooctyl acrylate, 70 parts of methyl methacrylate, 2 parts of methacrylic acid, 2 parts of glycidyl methacrylate and 0.5 parts of dodecyl sulfide Alcohol is added to an emulsifier solution consisting of 3 parts of allyloxynonylphenol polyethylene (10) ether ammonium sulfate and 30 parts of deionized water, and emulsified at high speed for 30 minutes to make a pre-emulsion;

[0038] (2) Add 1.5 parts of ammonium persulfate to 15 parts of deionized water, stir to dissolve, and obtain ammonium persulfate solution;

[0039] (3) Preparation of emulsion: Add 105 parts of deionized water, 30 parts of EVA emulsion, 3 parts of allyloxy nonylphenol poly Ethylene (10) ether ammonium sulfate, 1 part of sodium bicarbonate, and stir. When the temperature of the material in the reaction vessel rises to 72°C, add 30% of the ammonium persulfate sol...

Embodiment 2

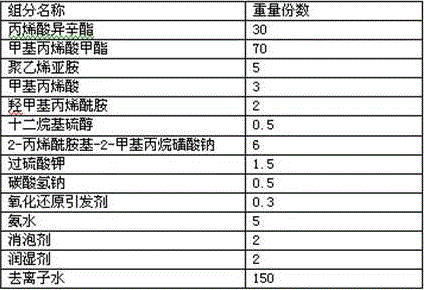

[0042] 1. Formula

[0043]

[0044] 2. Preparation

[0045] (1) Preparation of pre-emulsion: According to the above formula, 30 parts of butyl acrylate (dissolved with 10 parts of chlorinated polyolefin resin), 70 parts of methyl methacrylate, 3 parts of methacrylic acid, 3 parts of hydroxyethyl acrylate and 0.5 parts of dodecyl mercaptan are added to an emulsifier solution composed of 3 parts of 2-acrylamido-2-methylpropanesulfonate sodium and 30 parts of deionized water, and emulsified at high speed for 30 minutes to form a pre- Lotion;

[0046] (2) Add 1.5 parts of potassium persulfate to 15 parts of deionized water, stir to dissolve, and obtain potassium persulfate solution;

[0047] (3) Preparation of emulsion: Add 105 parts of deionized water, 20% of the pre-emulsion obtained in step (1), 3 parts of 2- Sodium acrylamido-2-methylpropane sulfonate, 1 part of sodium bicarbonate, and stirring, when the temperature of the material in the reaction vessel rises to 72°C, a...

Embodiment 3

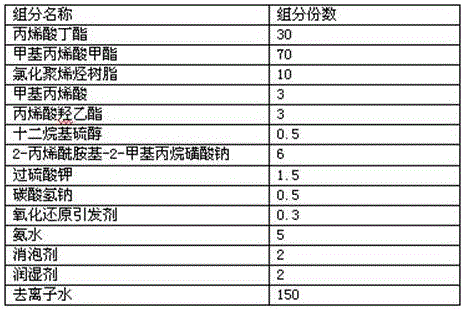

[0050] 1. Formula

[0051]

[0052] 3. Preparation

[0053] (1) Preparation of pre-emulsion: According to the above formula, 30 parts of butyl acrylate, 50 parts of methyl methacrylate, 20 parts of vinyl acetate, 3 parts of methacrylic acid, 2 parts of methylol acrylamide, 0.5 parts of ten Dialkyl mercaptan was added to an emulsifier solution consisting of 3 parts of 2-acrylamido-2-methylpropanesulfonate sodium and 30 parts of deionized water, and stirred and emulsified at high speed for 30 minutes to make a pre-emulsion;

[0054] (2) Add 1.5 parts of potassium persulfate to 15 parts of deionized water, stir to dissolve, and obtain potassium persulfate solution;

[0055] (3) Preparation of emulsion: Add 105 parts of deionized water, 20% of the pre-emulsion prepared in step (1), 3 parts 2-acrylamido-2-methylpropane sodium sulfonate, 1 part of sodium bicarbonate, and stir; when the temperature of the material in the reaction vessel rises to 72°C, add 30% of the potassium pe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com