PC/ABS composite based on basalt fiber reinforcement and preparation method thereof

A technology of basalt fiber and composite materials, which is applied in the field of basalt fiber-reinforced PC/ABS composite materials and its preparation, can solve the problems of tensile strength and impact strength enhancement, and achieve good impact strength, excellent performance, and tensile strength. Intensity highlights the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

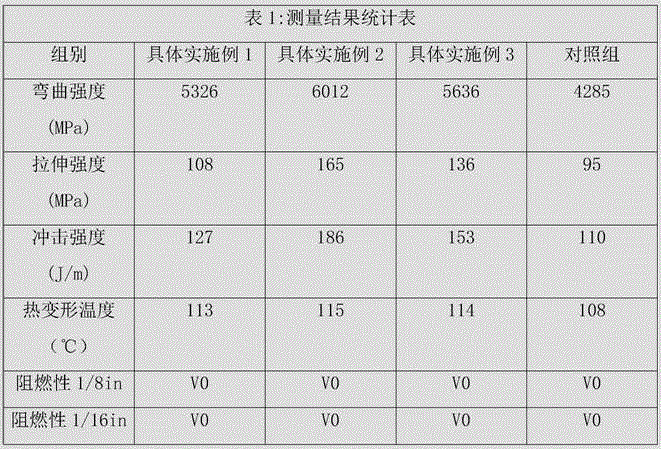

[0028] The PC / ABS composite material reinforced based on basalt fiber includes the following components in parts by weight, 55 parts of PC; 25 parts of ABS; 4 parts of basalt fiber; 4 parts of toughening agent; 1.3 parts of lubricant; 0.5 part of coupling agent; 3 parts of compatibilizer; 6 parts of flame retardant; 1 part of flame retardant synergist; 0.2 part of antioxidant.

[0029] Among them, the basalt fiber is a continuous fiber with an aspect ratio of 1500; the coupling agent is KH-550 obtained by compounding and sizing epoxy resin E51 and alicyclic epoxy; the toughening agent is styrene, acrylonitrile-butadiene The core-shell polymer of rubber, the rubber content in the toughening agent is 63%; the lubricant is a stearamide lubricant; the antioxidant is tetrakis[methyl-β-(3,5-di-t-butyl-4 -Hydroxyphenyl) propionate] pentaerythritol ester; compatibilizer is copolymer of styrene and maleic anhydride; flame retardant is decabromodiphenylethane such as 4010, brominated ep...

specific Embodiment 2

[0033] The PC / ABS composite material reinforced based on basalt fiber comprises the following components in parts by weight, 50 parts of PC; 20 parts of ABS; 14 parts of basalt fiber; 4 parts of toughening agent; 1.3 parts of lubricant; 0.5 part of coupling agent; 3 parts of compatibilizer; 6 parts of flame retardant; 1 part of flame retardant synergist; 0.2 part of antioxidant.

[0034] Among them, the basalt fiber is a continuous fiber with an aspect ratio of 1500; the coupling agent is KH-550 obtained by compounding and sizing epoxy resin E51 and alicyclic epoxy; the toughening agent is styrene, acrylonitrile-butadiene The core-shell polymer of rubber, the rubber content in the toughening agent is 63%; the lubricant is a stearamide lubricant; the antioxidant is tetrakis[methyl-β-(3,5-di-t-butyl-4 -Hydroxyphenyl) propionate] pentaerythritol ester; compatibilizer is copolymer of styrene and maleic anhydride; flame retardant is decabromodiphenylethane such as 4010, brominated ...

specific Embodiment 3

[0038] The PC / ABS composite material reinforced based on basalt fiber comprises the following components in parts by weight, 47 parts of PC; 17 parts of ABS; 20 parts of basalt fiber; 4 parts of toughening agent; 1.3 parts of lubricant; 0.5 part of coupling agent; 3 parts of compatibilizer; 6 parts of flame retardant; 1 part of flame retardant synergist; 0.2 part of antioxidant.

[0039] Among them, the basalt fiber is a continuous fiber with an aspect ratio of 1500; the coupling agent is KH-550 obtained by compounding and sizing epoxy resin E51 and alicyclic epoxy; the toughening agent is styrene, acrylonitrile-butadiene The core-shell polymer of rubber, the rubber content in the toughening agent is 63%; the lubricant is a stearamide lubricant; the antioxidant is tetrakis[methyl-β-(3,5-di-t-butyl-4 -Hydroxyphenyl) propionate] pentaerythritol ester; compatibilizer is copolymer of styrene and maleic anhydride; flame retardant is decabromodiphenylethane such as 4010, brominated ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com