Multifunctional liquid foam used for underground coal mine and using method thereof

A multi-functional, liquid technology, used in mining equipment, earth-moving drilling, safety devices, etc., can solve the problems of difficult liquid retention, short stabilization time, easy to flow away, etc. The effect of preventing the deterioration of the solution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

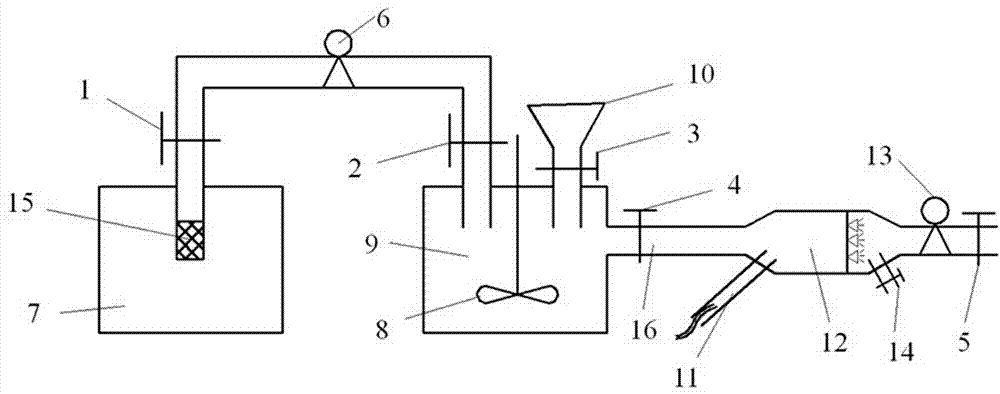

Image

Examples

Embodiment 1

[0028] Multifunctional liquid foam used for underground coal mine operations. Its components are calculated by mass percentage and consist of whisker inhibitor, quaternary ammonium salt cationic surfactant, nonionic surfactant, auxiliary agent and water. The inhibitor is aluminum borate whisker, which accounts for 0.5% of the total mass of the liquid foam, and the quaternary ammonium salt cationic surfactant is dodecyltrimethylammonium chloride, which accounts for 5% of the total mass of the liquid foam. Non-ionic surface active The agent is a polyoxyethylene alkanolamide with 3 to 4 moles of ethylene oxide, which accounts for 5% of the total mass of the liquid foam, and the auxiliary agent is a foam stabilizer and a solubilizer, which accounts for 5% of the total mass of the liquid foam. The foam stabilizer is modified polyanionic cellulose, which accounts for 50% of the weight of the auxiliary agent, the solubilizer is Tween-20, and the balance is water.

Embodiment 2

[0030] Multifunctional liquid foam used for underground coal mine operations. Its components are calculated by mass percentage and consist of whisker inhibitor, quaternary ammonium salt cationic surfactant, nonionic surfactant, auxiliary agent and water. The inhibitor is magnesium borate whisker, which accounts for 5% of the total mass of liquid foam, and the quaternary ammonium salt cationic surfactant is dodecyl dimethyl benzyl ammonium chloride, which accounts for 0.5% of the total mass of liquid foam, non-ionic The surfactant is fatty alcohol ether ammonium sulfate, which accounts for 15% of the total mass of liquid foam, and the auxiliary agent is foam stabilizer and solubilizer, which accounts for 10% of the total mass of liquid foam. The foam stabilizer is sodium carboxymethyl cellulose, which accounts for 80% of the weight of the auxiliary agent, the solubilizer is pentaerythritol, and the balance is water.

Embodiment 3

[0032] Multifunctional liquid foam used for underground coal mine operations. Its components are calculated by mass percentage and consist of whisker inhibitor, quaternary ammonium salt cationic surfactant, nonionic surfactant, auxiliary agent and water. The inhibitor is basic magnesium sulfate whisker, which accounts for 10% of the total mass of liquid foam, and the quaternary ammonium salt cationic surfactant is stearyl dimethyl hydroxyethyl ammonium nitrate, which accounts for 30% of the total mass of liquid foam. The non-ionic surfactant is ammonium laureth sulfate, which accounts for 0.5% of the total mass of liquid foam. The auxiliary agent is foam stabilizer and solubilizer, which accounts for 3% of the total mass of liquid foam. Among them, the foam stabilizer is coconut oil II. Ethanolamide accounts for 50% of the weight of the additives, the solubilizer is polyoxyethylene polypropylene block polyether, and the balance is water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com