Method for modifying carbon negative polar material

A carbon negative electrode material and technology of negative electrode materials, applied in the field of electrochemical materials, can solve problems such as cycle performance degradation, poor adhesion, and limited selection of negative electrode materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 100 grams of MCMB10-28 (manufactured by Osaka Gas Co., Ltd., Japan) was mixed with 500 grams of lithium hydroxide aqueous solution containing 1 wt%, and reacted at 30° C. for 80 hours. Then wash until the pH is 7.5, and dry in a drying oven to obtain a modified carbon negative electrode material.

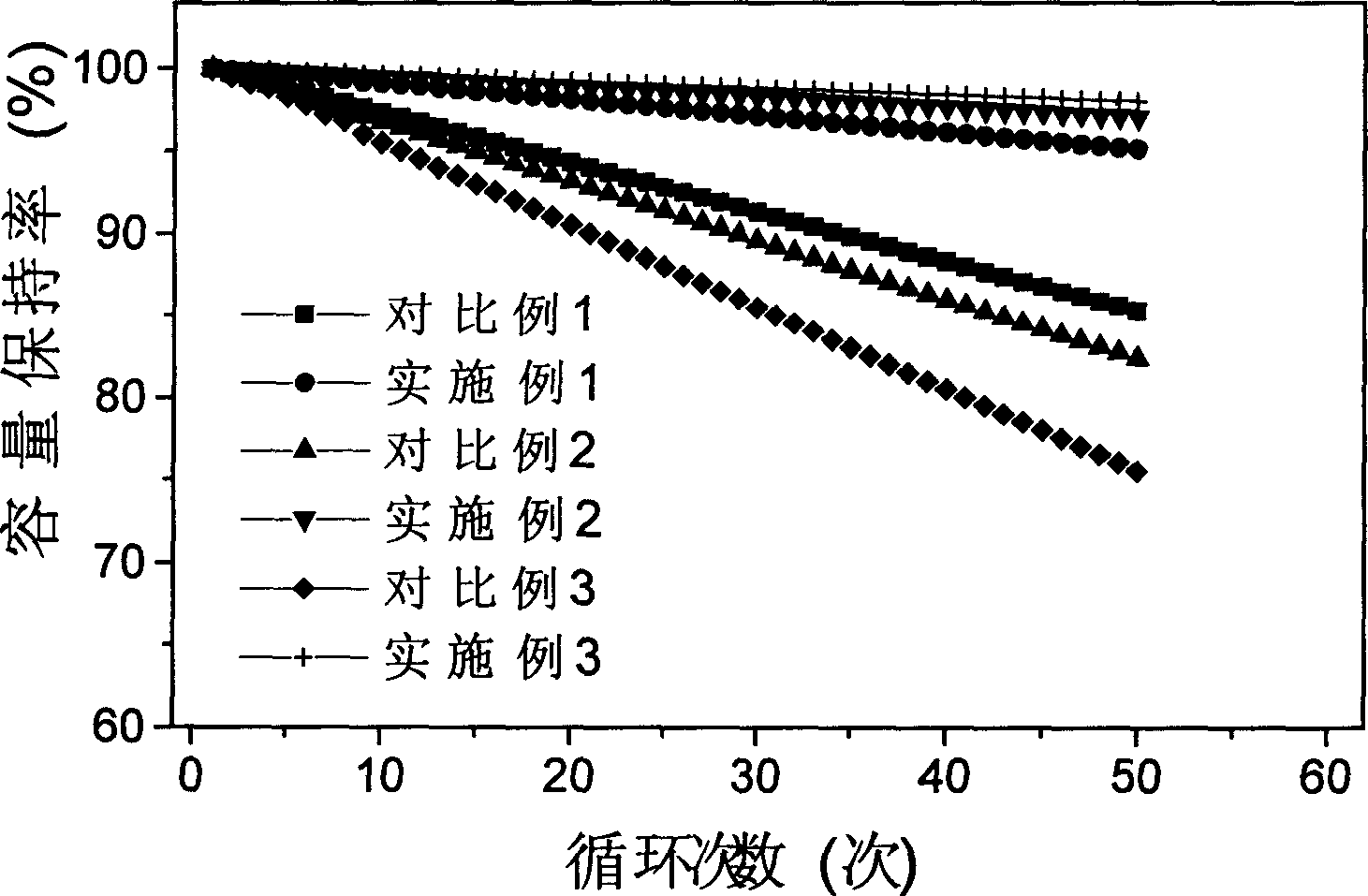

[0024] The preparation of the negative electrode was the same as that of Comparative Example 1, and the test of electrochemical performance was the same as that of Comparative Example 1 except that the modified negative electrode material obtained in this example was used as the negative electrode material. The relationship between capacity retention and cycle number is shown in figure 1 . The figure shows that after 50 cycles, the capacity retention is 95.1%.

Embodiment 2

[0028] Mix 100 grams of CMS (manufactured by Shanghai Shanshan Technology Co., Ltd.) with 300 grams of lithium carbonate aqueous solution containing 5 wt%, and react at 100°C for 2 hours. Then it was washed until the pH was 7.0, and dried in a drying oven to obtain a modified carbon negative electrode material.

[0029] The preparation of the negative electrode was the same as that of Comparative Example 1, and the test of electrochemical performance was the same as that of Comparative Example 1 except that the modified negative electrode material obtained in this example was used as the negative electrode material. The relationship between capacity retention and cycle number is shown in figure 1 . The figure shows that after 50 cycles, the capacity retention is 97.0%.

Embodiment 3

[0033] 100 grams of spherical graphite with a carbon content greater than 99.9% (produced by Shandong Qingdao Taineng Graphite Co., Ltd.) was mixed with 100 grams of 10 wt% lithium nitrate aqueous solution, and reacted at 60° C. for 24 hours. Then wash until the pH is 6.5, and dry in a drying oven to obtain a modified carbon negative electrode material.

[0034] The preparation of the negative electrode was the same as that of Comparative Example 1, and the test of electrochemical performance was the same as that of Comparative Example 1 except that the modified negative electrode material obtained in this example was used as the negative electrode material. The relationship between capacity retention and cycle number is shown in figure 1 . The figure shows that after 50 cycles, the capacity retention is 98.0%.

[0035] It can be seen from the comparative examples and corresponding examples that the modified carbon negative electrode material produced by the present inventio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com