Crosslinkable polyethylene co-mixed composition

A technology of crosslinked polyethylene and composition, applied in the field of crosslinkable polyethylene blend composition

Active Publication Date: 2014-06-18

NAT INST OF CLEAN AND LOW CARBON ENERGY

View PDF16 Cites 18 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the cross-linked material still needs to further improve the toughness

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

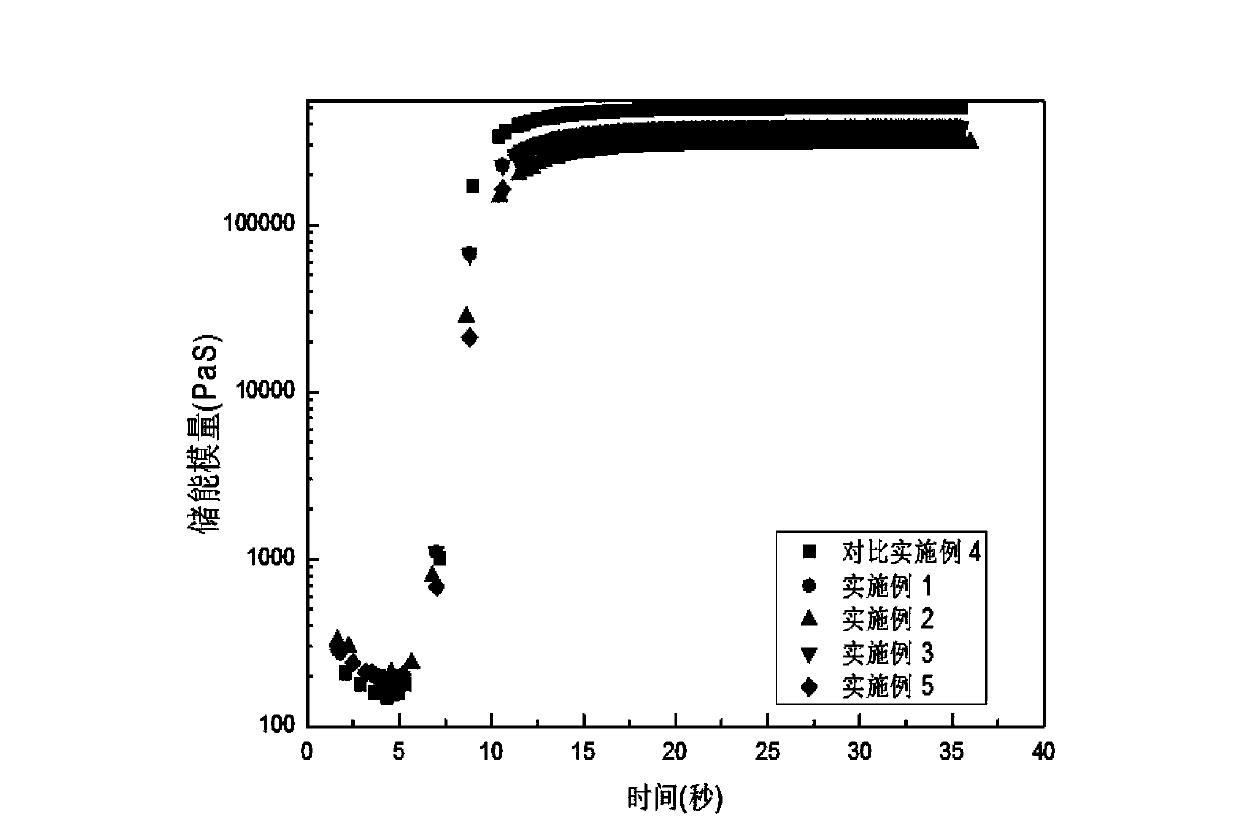

Embodiment 1-7 and comparative Embodiment 1-5

[0052] The crosslinkable polyethylene compositions of Examples 1-7 and Comparative Examples 1-5 were prepared by extruding with a twin-screw extruder at 150° C. and 80 rpm, and then cut and pelletized. The specific models and contents of various components are shown in Table 1 and Table 2, respectively.

[0053] Table 1

[0054]

[0055]

[0056] Table 2

[0057]

[0058]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a crosslinkable polyethylene co-mixed composition, a preparation method thereof and a product prepared therefrom. Specifically, the invention relates to the crosslinkable polyethylene composition having improved adhesive power to metals, the preparation method thereof and the product prepared therefrom. The crosslinkable polyethylene composition comprises the components: (a) 100 parts by weight of polyethylene resin; (b) 0.5-12 parts by weight of polyolefin grafted with an unsaturated carboxylic acid, anhydride and / or an ester derivative thereof; (c) 0.2-6 parts by weight of a peroxide crosslinking agent; and (d) optionally, 0.01-10 parts by weight of an auxiliary agent. The crosslinkable polyethylene composition after crosslinking has excellent adhesive power to various metals (such as aluminum, copper and steel) and other polar materials.

Description

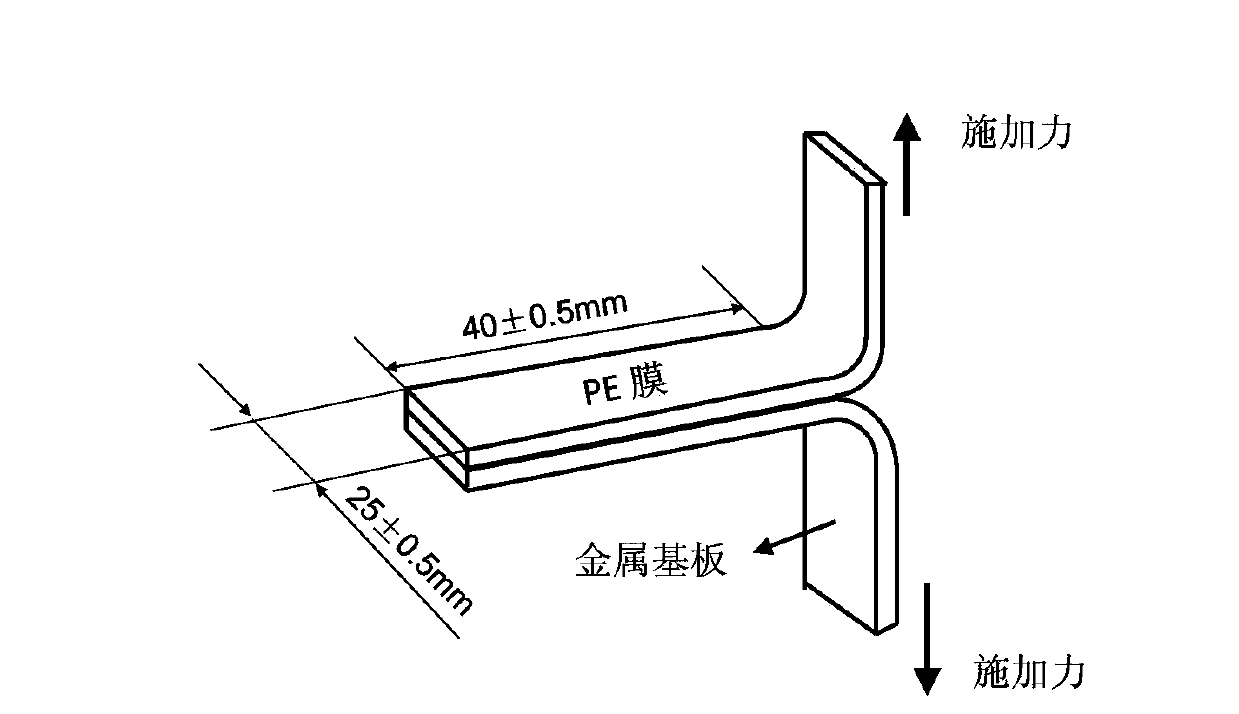

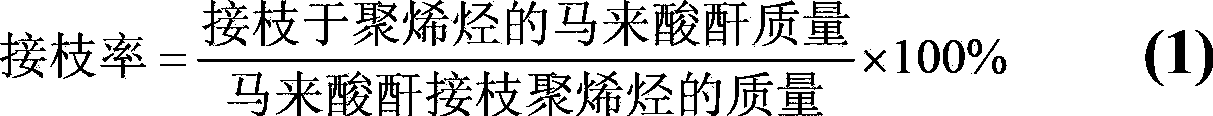

technical field [0001] The present invention relates to a cross-linkable polyethylene blend composition, in particular, to a cross-linkable polyethylene blend composition with improved toughness and metal adhesion, a preparation method thereof and articles prepared therefrom . Background technique [0002] Crosslinkable polyethylene compositions can have high performance, including excellent chemical resistance, high heat distortion temperature, good impact strength and low coefficient of thermal expansion. However, it shows very poor adhesion to polar substrates such as metals because it is a low polar polymer. There is therefore a need for crosslinkable polyethylene resins having improved adhesion to various metals. [0003] In order to improve the adhesion of conventional polyolefins to polar surfaces, it is necessary to modify their surface. Commonly used pretreatment techniques include: chemical etching (such as chromic acid etching), surface coating adhesives, micro...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C08L23/06C08L23/08C08L51/06C08K5/14C08J3/24

CPCB29C48/92B29C2948/92704C08L23/06C08L2205/03C08L2207/062C08L2312/00C08L23/0815C08L51/06C08K5/14

Inventor 陈学连梁文斌牛艳华赖世燿

Owner NAT INST OF CLEAN AND LOW CARBON ENERGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com