Glass fiber reinforced polypropylene graft microcellular foaming material and preparation method thereof

A technology of microporous foam material and polypropylene grafting, which is applied in the field of polymer materials, can solve problems such as tensile strength reduction, application limitations, and use of structural materials, so as to solve the problem of dispersion, expand the scope of application, and solve dust Flappy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

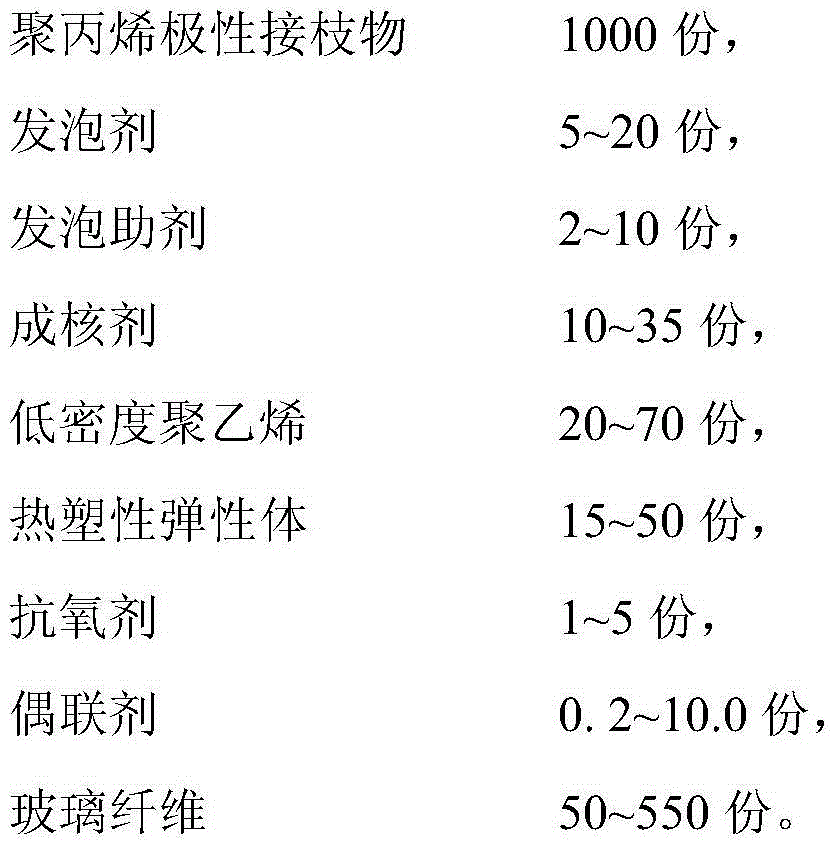

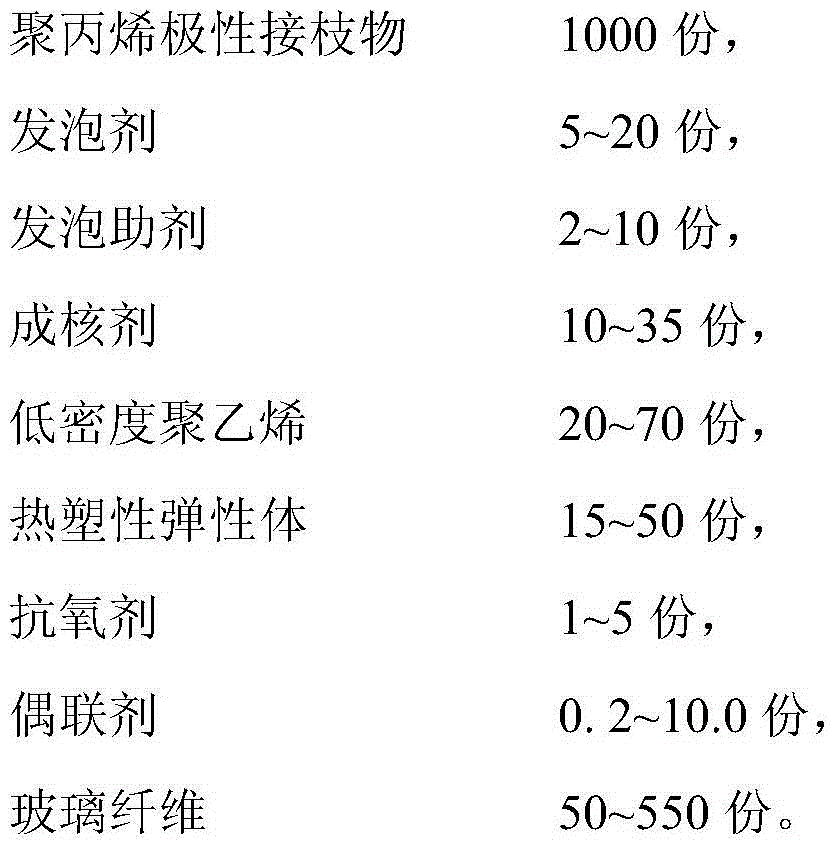

Method used

Image

Examples

Embodiment 1

[0034] (1) 5 parts of foaming agent azodicarbonamide (AC), 10 parts of nucleating agent talcum powder, 15 parts of thermoplastic elastomer polyolefin elastomer (POE) and 20 parts of low-density polymer were mixed by twin-screw extruder. Ethylene extrusion, granulation, prepared into foam masterbatch, extrusion temperature is 135 ~ 155 ℃;

[0035] (2) Dissolve 5.0 parts of coupling agent 3-aminopropyltriethoxysilane (KH550) in water and ethanol to prepare a coupling agent-ethanol solution with a concentration of 1.5%, and spray the solution by spraying method On 300 parts of chopped glass fiber (8.0 mm in length), dry the glass fiber sprayed with coupling agent solution in an oven at 110°C for 45 minutes; Fiber, 2 parts of foaming aid calcium stearate and 1000 parts of polypropylene grafted material maleic anhydride grafted polypropylene (PP-g-MAH) are extruded and granulated, and the extrusion temperature is 195-215 °C;

[0036] (3) Combine the foam masterbatch in (1), the pe...

Embodiment 2

[0038] (1) 8 parts of foaming agent azodicarbonamide (AC), 16 parts of nucleating agent talc, 24 parts of thermoplastic elastomer polyolefin elastomer (POE) and 32 parts of low density polystyrene were mixed by twin-screw extruder. Ethylene extrusion, granulation, prepared into foam masterbatch, extrusion temperature is 135 ~ 155 ℃;

[0039] (2) Dissolve 5.0 parts of coupling agent 3-aminopropyltriethoxysilane (KH550) in water and ethanol to prepare a coupling agent-ethanol solution with a concentration of 1.5%, and spray the solution by spraying method On 300 parts of chopped glass fiber (8.0 mm in length), dry the glass fiber sprayed with coupling agent solution in an oven at 110°C for 45 minutes; Fiber, 4 parts of foaming aid calcium stearate and 1000 parts of polypropylene grafted material maleic anhydride grafted polypropylene (PP-g-MAH) are extruded and granulated, and the extrusion temperature is 195-215 °C;

[0040] (3) Combine the foam masterbatch in (1), the pellets...

Embodiment 3

[0042](1) 12.5 parts of foaming agent azodicarbonamide (AC), 25 parts of nucleating agent talc, 37.5 parts of thermoplastic elastomer polyolefin elastomer (POE) and 50 parts of low-density polymer were mixed by twin-screw extruder. Ethylene extrusion, granulation, prepared into foam masterbatch, extrusion temperature is 135 ~ 155 ℃;

[0043] (2) Dissolve 5.0 parts of coupling agent 3-aminopropyltriethoxysilane (KH550) in water and ethanol to prepare a coupling agent-ethanol solution with a concentration of 1.5%, and spray the solution by spraying method On 300 parts of chopped glass fiber (8.0 mm in length), dry the glass fiber sprayed with coupling agent solution in an oven at 110°C for 45 minutes; Fiber, 6 parts of foaming aid calcium stearate and 1000 parts of polypropylene grafted material maleic anhydride grafted polypropylene (PP-g-MAH) are extruded and granulated, and the extrusion temperature is 195-215 °C;

[0044] (3) Combine the foam masterbatch in (1), the pellets...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com