Active-carbon-microball coated metal composition negative polar material and preparing method

A technology of metal composites and negative electrode materials, applied in battery electrodes, electrical components, circuits, etc., can solve problems such as limited stability, complicated preparation process, and high raw material prices, and achieve good industrial application value, high charging specific capacity, and preparation The effect of simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

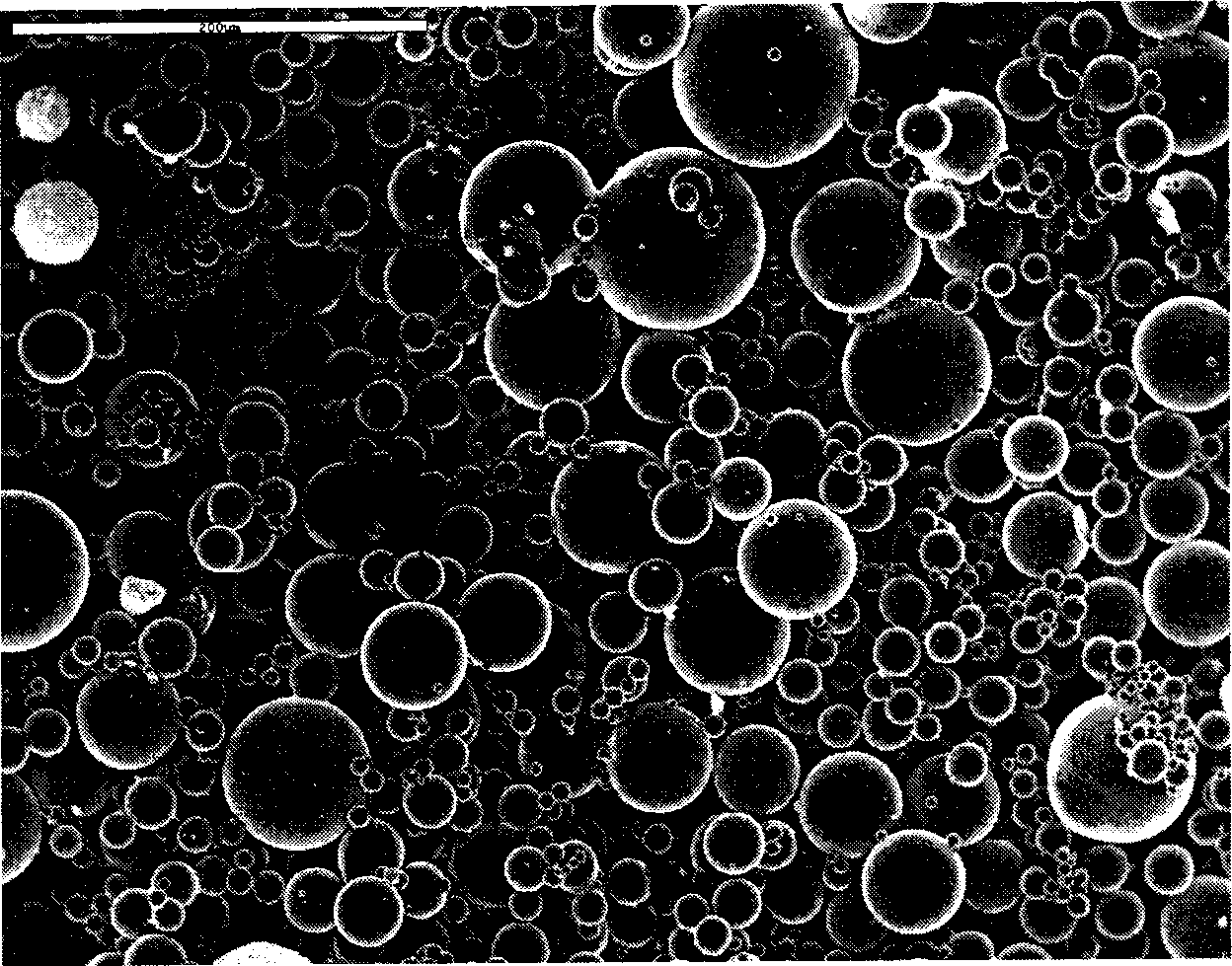

Image

Examples

example 1

[0030] Dissolve 5.5g of resorcinol in 5mL of formaldehyde solution (37%), then add deionized water to make a 20mL clear solution, add 0.0275g of anhydrous NaOH as a catalyst, and then add 1g of ball-milled SnO 2 powder, stir well. This solution was then dispersed in 200 mL of kerosene dissolved with 12 g of SPAN80 to form a reverse micellar emulsion. At 20° C., the rotation speed was 200 rpm to carry out the phenolic polymerization reaction for 24 hours, and then the phenolic gel balls were obtained. The obtained solid microspheres were freed of surface-adhered kerosene in vacuum at 200 °C. Then, in the tubular reactor, under the protection of nitrogen atmosphere, the temperature was raised to 800°C, and the temperature was kept constant for 2 hours. After the resin carbonization and carbothermal reduction process, and finally cooled naturally in the furnace, the activated carbon microsphere-coated metal tin spherical composite was obtained. material. The measured average p...

example 2

[0032] Dissolve 5.5g resorcinol in 10mL formaldehyde solution (37%), then add deionized water to make a 20mL clear solution, add 0.05g anhydrous Na 2 CO 3 As a catalyst, 2 g of ball-milled SnO 2powder, stir well. The solution was then dispersed in 400 mL of kerosene dissolved in 15 g of SPAN80 to form a reverse micellar emulsion. At 30° C., stirring at 600 rpm to carry out phenolic polymerization reaction for 24 hours, to obtain phenolic gel balls. The obtained solid microspheres were freed of surface-adhered kerosene in vacuum at 200 °C. Then, in the tubular reactor, under the protection of nitrogen atmosphere, the temperature was raised to 900°C, and the temperature was kept constant for 2 hours. After resin carbonization and carbothermal reduction process, and finally cooled naturally in the furnace, the spherical composite of activated carbon microspheres coated with metal tin was obtained. material. It is measured that the average particle diameter of the product is ...

example 3

[0034] Dissolve 5.5g resorcinol in 15mL formaldehyde solution (37%), then add deionized water to make a 20mL clear solution, add 0.165g anhydrous NaCO 3 As a catalyst, 5 g of ball-milled SnO 2 powder, stir well. This solution was then dispersed in 1000 mL of cyclohexylamine dissolved in 10 g of SPAN80 to form a reverse micellar emulsion. At 80° C., with stirring at 1200 rpm, the phenolic gel was polymerized for 3 hours to obtain phenolic gel balls. The obtained solid microspheres were freed of surface-adhered cyclohexylamine in vacuum at 200°C. Then, in the tubular reactor, under the protection of nitrogen atmosphere, the temperature was raised to 1200°C, and the temperature was kept constant for 2 hours. After resin carbonization and carbothermal reduction process, and finally cooled naturally in the furnace, the spherical composite of activated carbon microspheres coated with metal tin was obtained. material. It is measured that the average particle size of the product i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com