Extraction head of carbon nano-tube solid phase micro-extraction and preparation thereof

A carbon nanotube and extraction head technology, which is applied in the field of analytical chemistry, can solve the problems that the adsorption capacity of substances needs to be improved, the applicable temperature is low, the probe cannot be used, etc., and achieves the effects of wide application range, improved efficiency and simple preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Soak the stainless steel fiber in acetone for 2 hours, remove the dirt attached to the outer layer, take it out and dry it for later use; weigh 2 mg of carbon nanotubes into a centrifuge plastic tube, add 40 μL of deionized water and 400 μL of trimethoxysilane, and Place in an ultrasonic oscillator and vibrate for 30 minutes, then add 200 μL of trifluoroacetic acid and a drop of polymethylsiloxane to the above mixture, and continue to vibrate for 6 minutes; soak one end of the above-mentioned treated stainless steel fiber in the above-mentioned sol- Gel solution, and repeatedly pulled until the coating length reached 1cm, thickness reached 80μm; the stainless steel fiber was placed in a desiccator at room temperature for 24 hours, and then placed in the gasification chamber of the gas chromatography at 150 ° C with nitrogen After 30 minutes, the temperature was raised to 180° C. and kept for 30 minutes, then gradually raised to 250° C., kept for 2 hours, taken out and co...

Embodiment 2

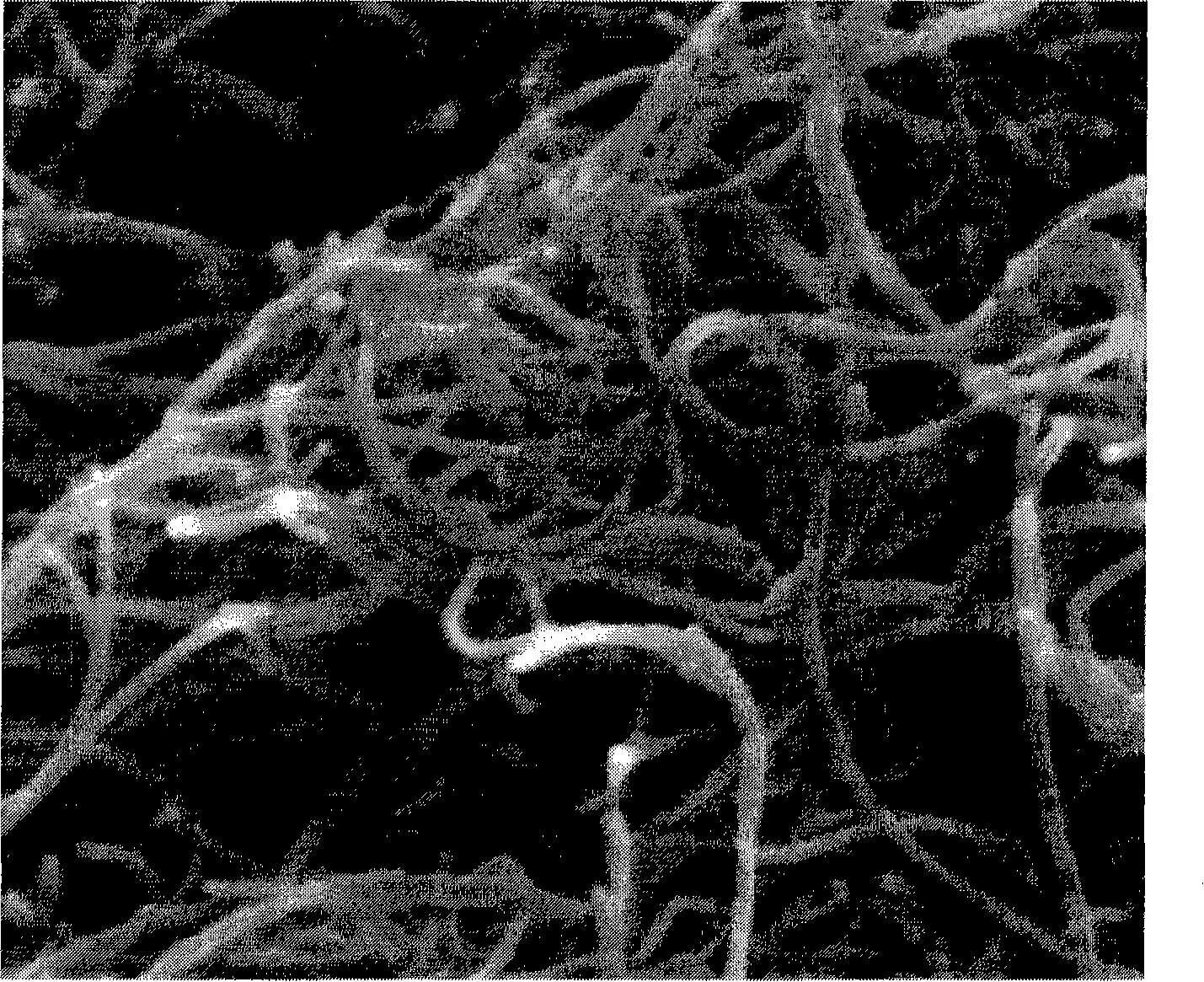

[0028] Soak the stainless steel fiber in acetone for 2 hours, remove the dirt attached to the outer layer, take it out and dry it for later use; coat one end of the stainless steel fiber with high-temperature glue, insert it into the carbon nanotube powder, until the coated carbon nanotube coating length reaches 1cm, thickness up to 60μm; place the stainless steel fiber in a desiccator to dry at room temperature for 24 hours, then place it in the vaporization chamber of the gas chromatography at 150°C for 30 minutes with nitrogen, then raise the temperature to 180°C for 30 minutes and then gradually increase the temperature to Keep at 250°C for 2 hours, take it out and cool to room temperature to obtain an extraction tip. The microscopic morphology of the prepared extraction head was characterized by scanning electron microscopy, such as figure 2 As shown in the figure, a large number of carbon nanotubes can be observed on the surface of the extraction head.

Embodiment 3

[0030] Soak the stainless steel fiber in acetone for 2 hours, remove the dirt attached to the outer layer, take it out and dry it for later use; weigh 2 mg of carbon nanotubes into a centrifuge plastic tube, add 40 μL of deionized water and 400 μL of trimethoxysilane, and Place in an ultrasonic oscillator and vibrate for 30 minutes, then add 200 μL of trifluoroacetic acid and a drop of polymethylsiloxane to the above mixture, and continue to vibrate for 6 minutes; soak one end of the above-mentioned treated stainless steel fiber in the above-mentioned sol- Gel solution, and repeatedly pulled, until the coating length reaches 1cm, thickness reaches 60μm, and then coated with high-temperature glue on the part of the stainless steel fiber coated with sol-gel solution, inserted into the carbon nanotube powder, until coated The coated carbon nanotube coating reached 100 μm; the stainless steel fiber was dried in a desiccator at room temperature for 24 hours, and then placed in the g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com