Method for producing polyolefin elastomer false skin and product thereof

A polyolefin elastomer, artificial leather technology, applied in layered products, synthetic resin layered products, chemical instruments and methods, etc., can solve the problem of unsolved adhesion of heterogeneous materials, easy to stick to the wheel, and cannot be applied to artificial leather And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

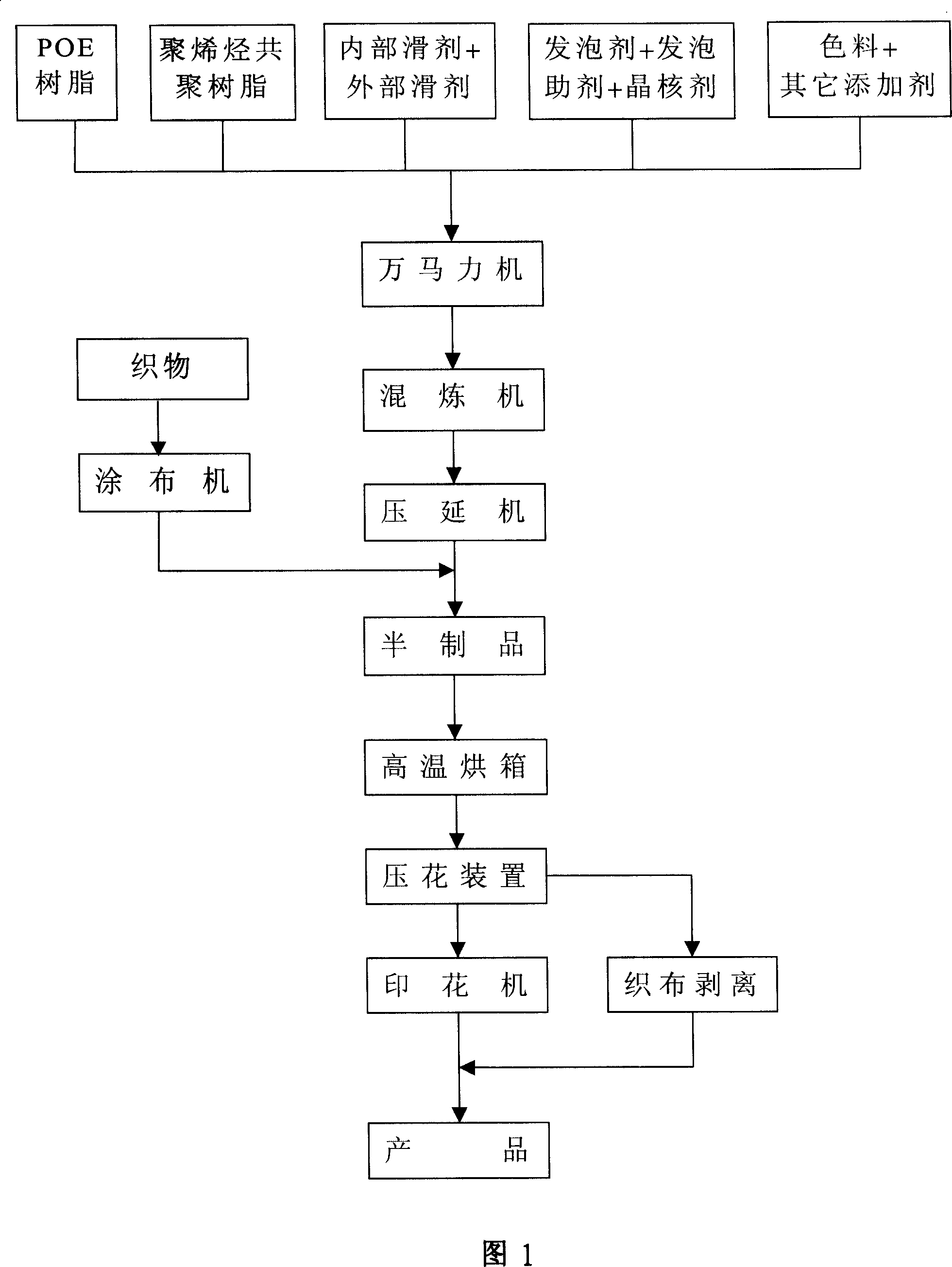

preparation example Construction

[0041] fabric preparation

[0042] Take a woven fabric blended with rayon and polyester, apply a layer of adhesive with a 40-mesh roller coating device, and dry it in an oven at 90°C.

[0043] Preparation of foam layer

[0044] Take the melt index (meiltindex, hereinafter referred to as MI) as 5 and the density as 0.865g / cm 3 Polyethylene elastomer (Engage(R) 7447) 70% with a MI of 1.6 and a density of 0.897 g / cm 3 30% of polyethylene elastomer (Engage ® 8440) is used as the base resin, and 10 parts by weight of EVA resin (Superplastic ® UE 659, vinyl acetate content 25%) is mixed with respect to 100 parts by weight of the base resin. 5 parts by weight of EMA resin (Elvaloy 1218AC, methyl acrylate content 18%), 5 parts by weight of ADCA (Azodicarbonamide, azodicarbonamide) blowing agent (Otsuka Chemical AZH), 0.6 parts by weight of stearic acid Zinc, 0.2 parts by weight of ethylene-bisstearamide (Kao EBS), 0.5 parts by weight of polyethylene wax, 10 parts by weight of ca...

Embodiment 1

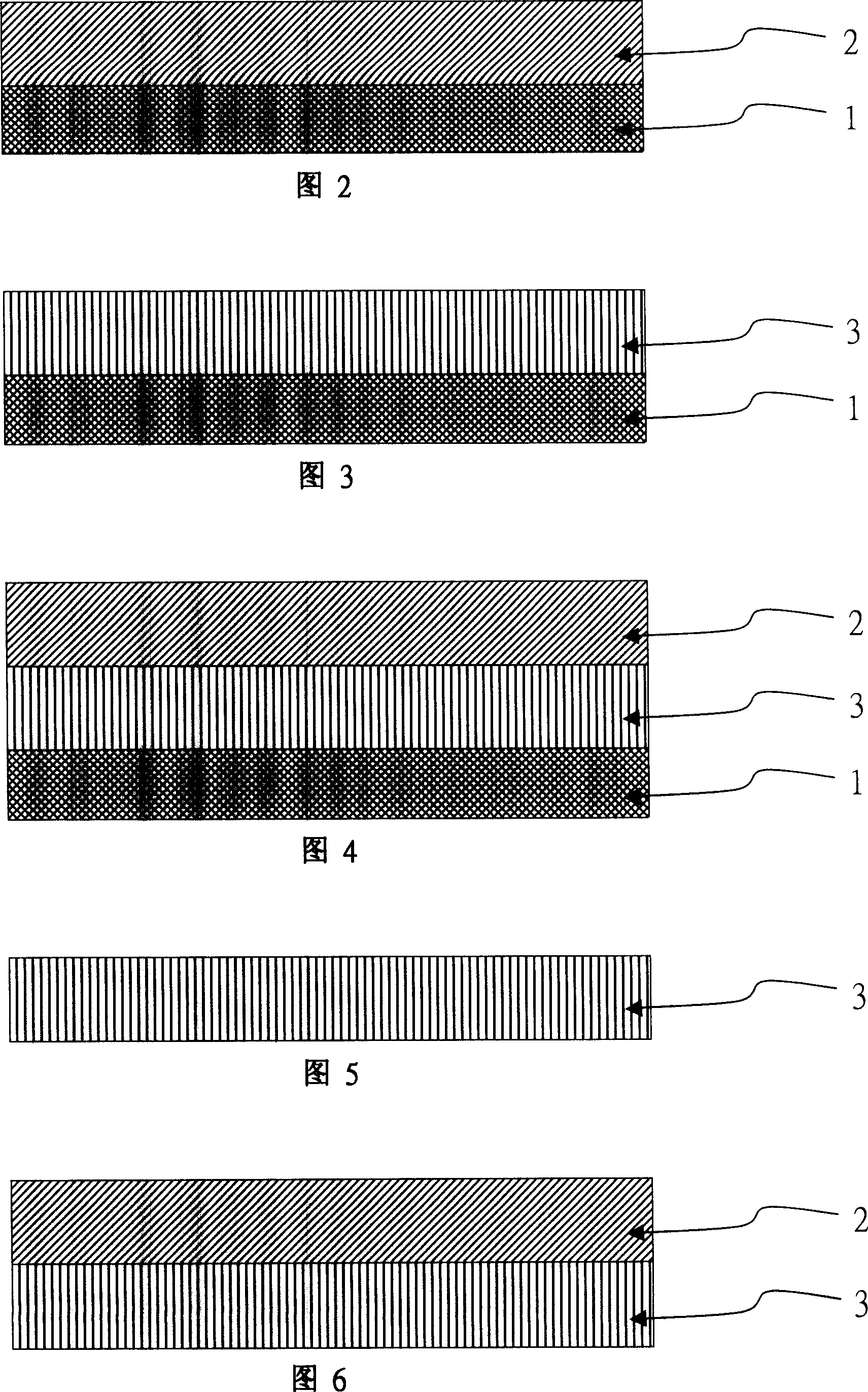

[0048] Example 1-leather (Figure 2)

[0049] On a calender, the formed surface layer (2) is attached to the pre-adhesive fabric (1), and then passed at a speed of 16 yards per minute at a temperature of 200°C, 190°C, and 190°C. and an oven at 165°C, and then the rubber is passed through an embossing device composed of two rollers, and finally cooled and coiled.

Embodiment 2

[0050] Example 2 - soft skin A (sponge A) (Figure 3)

[0051] On a calender, the formed foam layer (3) is attached to the pre-coated fabric (1), and then the passing temperature is 220°C, 220°C, 210°C at a speed of 12.4 inches per minute. ℃ and 185℃ high temperature oven to make it foam. Then make the soft leather A pass through an embossing device composed of two rollers, and finally be cooled and coiled.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com