Method for preparing high-performance lithium-ion battery diaphragm through vacuum ultraviolet grating modification

A lithium-ion battery, graft modification technology, applied in battery pack parts, circuits, electrical components and other directions, can solve the problems of difficult mass production, industrialized production, unfavorable production efficiency, long graft reaction time, etc. Achieve the effects of strong antioxidant capacity, improved affinity, and high cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

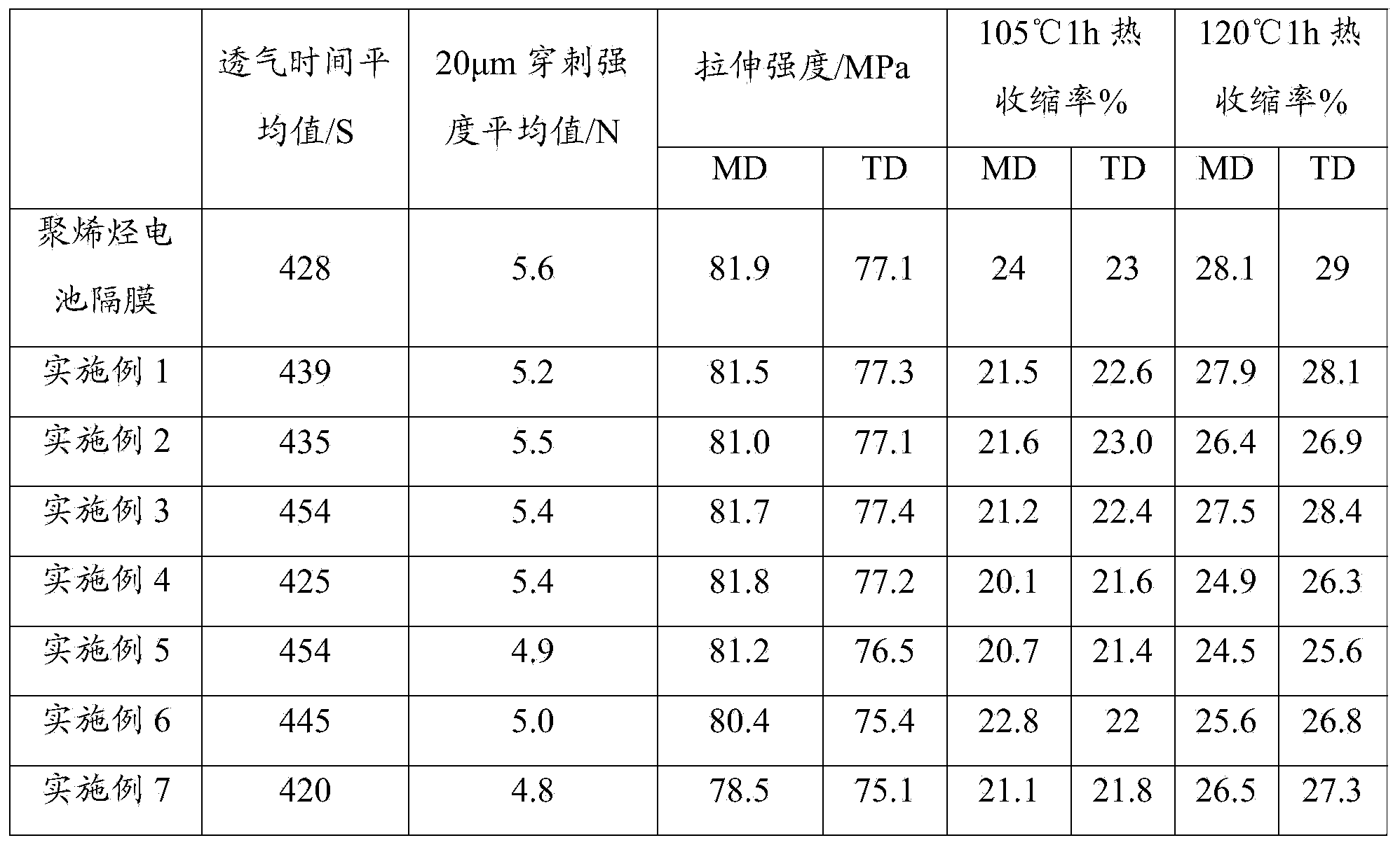

Embodiment 1

[0018] A method for preparing a high-performance lithium-ion battery separator by vacuum ultraviolet grafting modification: the polyethylene lithium-ion battery separator is exposed to an irradiation intensity of 14mW / cm 2 In the vacuum ultraviolet ray, irradiate for 30 seconds, the total amount of radiation is 420mJ / cm 2 ; Immerse the irradiated diaphragm rapidly in the methyl methacrylate monomer solution, perform grafting reaction for 5 seconds, take it out, quickly volatilize the unreacted monomer at 80°C, and finally obtain the graft-modified methyl methacrylate polyethylene lithium-ion battery separator.

Embodiment 2

[0020] A method for preparing a high-performance lithium-ion battery separator by vacuum ultraviolet grafting modification: the polyethylene lithium-ion battery separator is exposed to an irradiation intensity of 14mW / cm 2 In the vacuum ultraviolet ray, irradiate for 20 seconds, and the total amount of radiation is 280mJ / cm 2 Immerse the irradiated separator rapidly in the methyl acrylate monomer solution, perform grafting reaction for 5 seconds, take it out, quickly volatilize the unreacted monomer at 90°C, and finally obtain the polyethylene lithium grafted with methyl acrylate Ion battery separator.

Embodiment 3

[0022] A method for preparing a high-performance lithium-ion battery separator by vacuum ultraviolet grafting modification: the polyethylene lithium-ion battery separator is exposed to an irradiation intensity of 14mW / cm 2 In the vacuum ultraviolet ray, irradiate for 20 seconds, and the total amount of radiation is 280mJ / cm 2 ; Immerse the irradiated diaphragm rapidly in the glycidyl methacrylate monomer solution, graft the reaction for 5 seconds, take it out, quickly volatilize the unreacted monomer at 90°C, and finally obtain the glycidyl methacrylate graft Modified polyethylene lithium ion battery separator.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com