Fire-retardancy polyurethane composition containing no halogen and non-thermal contraction pipe using thereof

A thermoplastic polyurethane, flame retardant technology, applied in the field of flame retardant polyurethane composition, polyurethane flame retardant and non-heat shrinkable pipe, can solve the problems of poor wear resistance and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

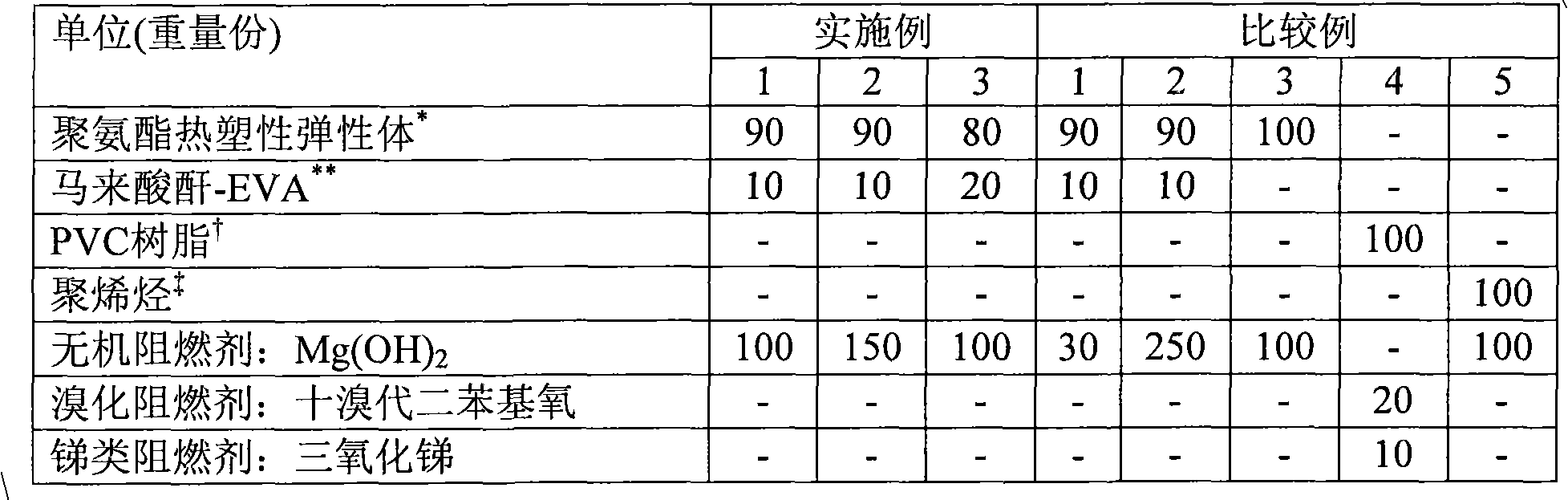

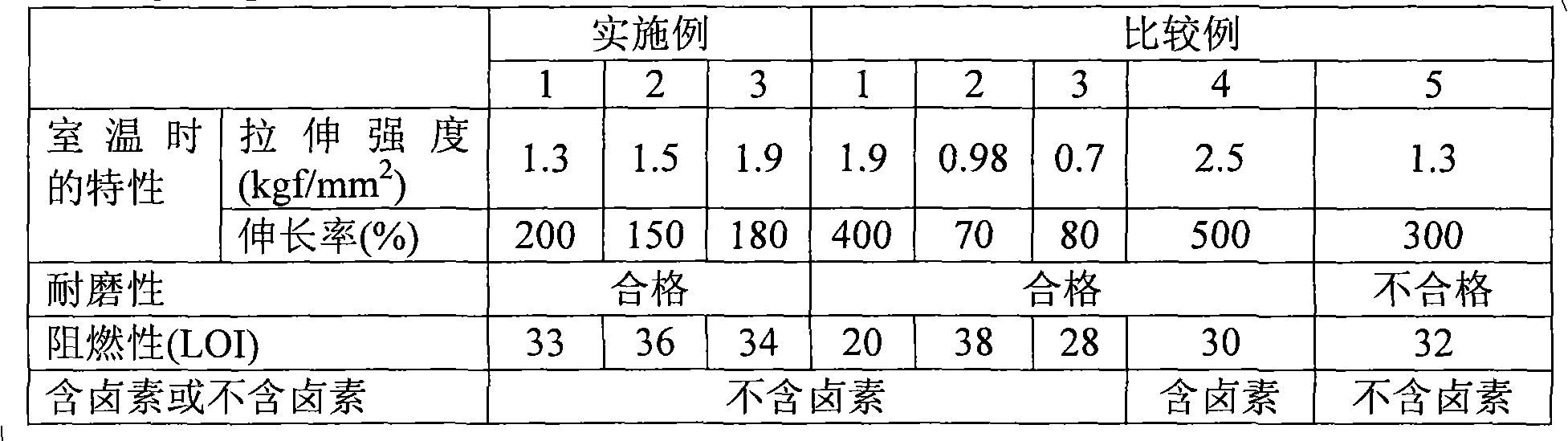

[0026] In order to compare the performance between the non-heat-shrinkable tube of the present invention and a conventional non-heat-shrinkable tube, flame-retardant resin compositions were prepared according to Examples and Comparative Examples. Non-heat-shrinkable tube samples were manufactured using the flame-retardant resin composition, and then their properties were evaluated.

[0027] The compositions of the flame-retardant resin compositions of Examples and Comparative Examples are shown in Table 1 below.

[0028] [Table 1]

[0029]

[0030] * : Polyurethane with a hardness of 87A, manufactured by SK Chemicals

[0031] ** : Ethylene-vinyl acetate resin grafted with 1% by weight of maleic anhydride

[0032] Polyvinyl chloride resin (polymerization degree: 1300) using diisodecyl phthalate as a plasticizer [polymer: plasticizer = 67% by weight: 33% by weight]

[0033] EVA resin with 25% by weight vinyl acetate monomer

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com