Glycidyl methacrylate grafted polylactic acid copolymer material, preparation method for same and application thereof

A polylactic acid copolymer and glycidyl ester technology, which is applied in the field of glycidyl methacrylate grafted polylactic acid copolymer materials and its preparation, can solve the problem of affecting the comprehensive performance of materials, and the coupling agent does not consider the related effects of polylactic acid matrix , small molecule coupling agent seepage and other problems, to achieve the effect of improving interfacial compatibility, improving mechanical properties, and no solvent pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

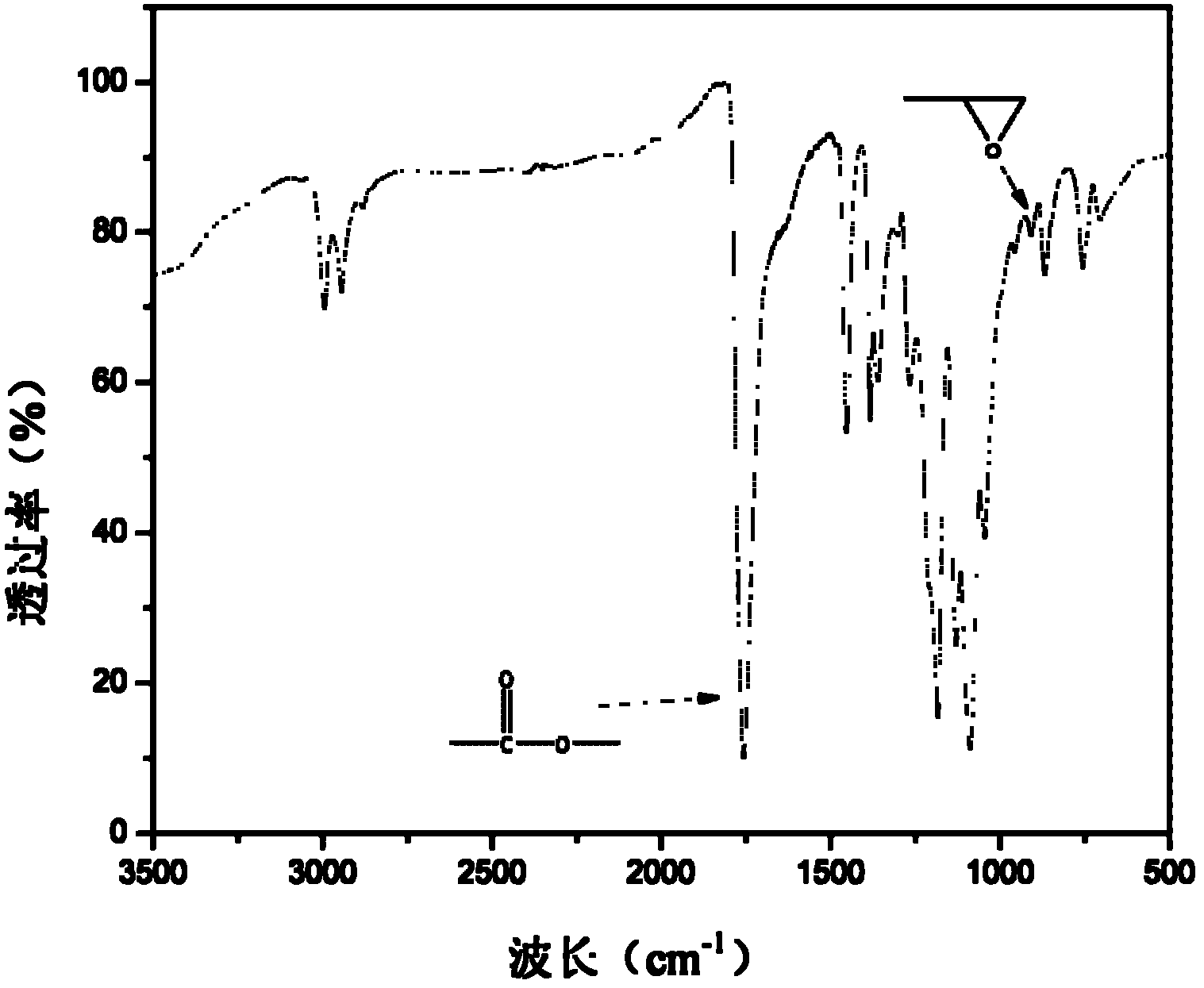

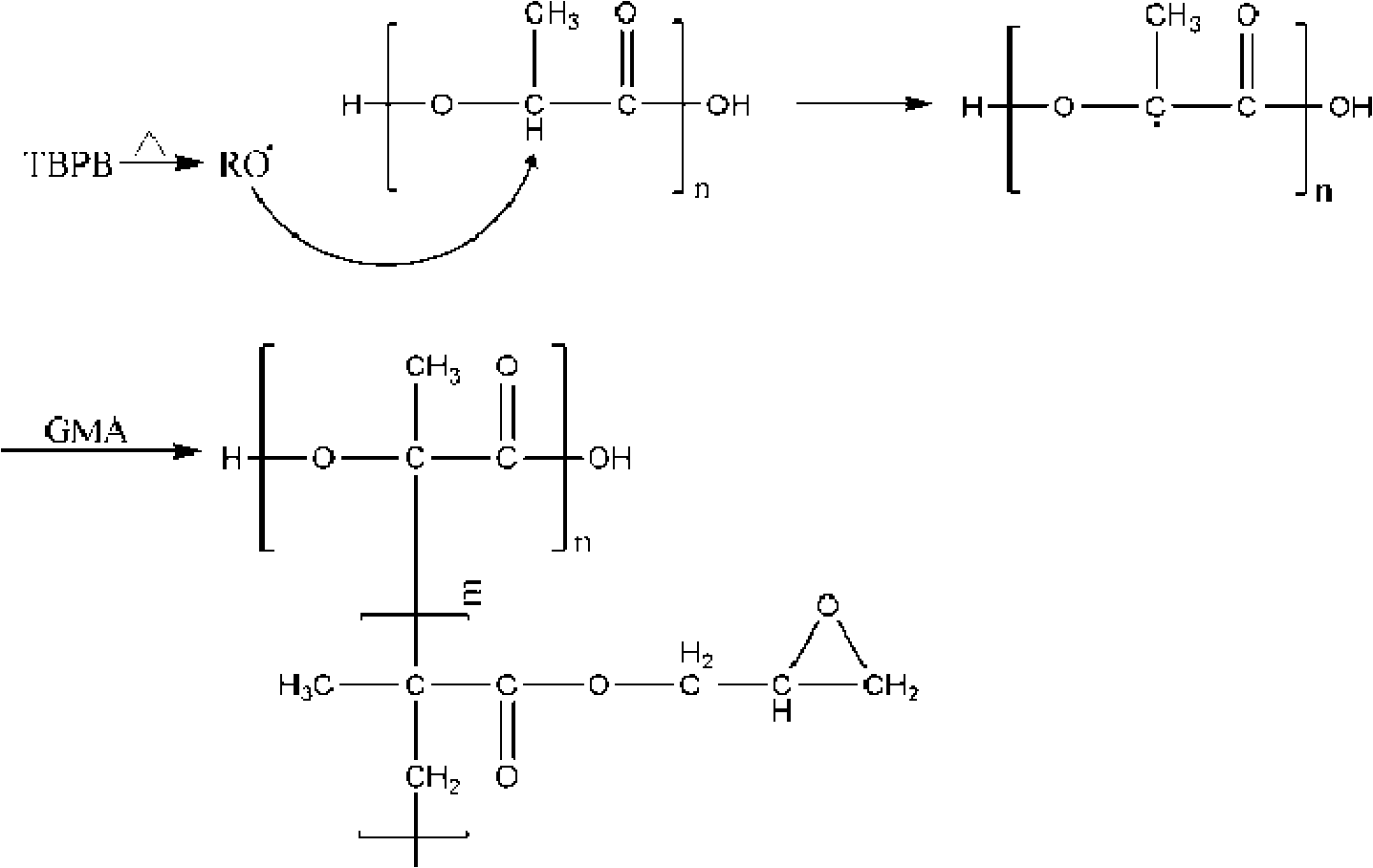

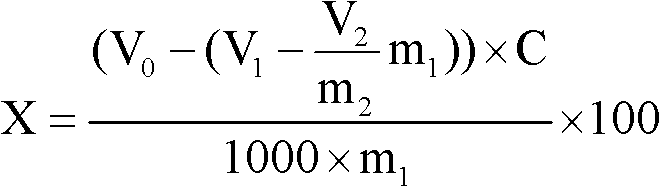

Embodiment 1

[0056] Take polylactic acid resin (the number average molecular weight is 100,000, Natureworks4032D, LD mixed type polylactic acid, L type is 97%, D type is 3%) 96.0% by weight percentage, glycidyl methacrylate 3.0%, peroxide 1.0% of tert-butyl benzoate is used as a mixed material; the mixed material is added to a twin-screw extruder for melt extrusion and granulation to obtain a granular product (ie glycidyl methacrylate grafted polylactic acid copolymer material). Among them, the temperature of each section of the mixed material in the twin-screw extruder is respectively: the temperature of the feeding section is 165°C, the temperature of the compression section is 175°C, the temperature of the metering section is 180°C, the temperature of the head is 185°C, and the speed of the twin-screw extruder is 300 rpm. The molecular weight, molecular weight distribution and epoxy value of the sample are shown in Table 1.

Embodiment 2

[0058] Take by weight percentage polylactic acid resin (number average molecular weight is 100,000, Natureworks4032D, LD mixed type polylactic acid, L type is 97%, D type is 3%) 94.0%, glycidyl methacrylate 5.0%, peroxide 1.0% of tert-butyl benzoate, after mixing uniformly, is used as a mixed material; the mixed material is added into a twin-screw extruder to melt and extrude, and granulated to obtain a granular product (i.e. glycidyl methacrylate grafted polylactic acid copolymer Material). Among them, the temperature of each section of the mixed material in the twin-screw extruder is respectively: the temperature of the feeding section is 165°C, the temperature of the compression section is 175°C, the temperature of the metering section is 180°C, the temperature of the head is 185°C, and the speed of the twin-screw extruder is 300 rpm. The molecular weight, molecular weight distribution and epoxy value of the sample are shown in Table 1.

Embodiment 3

[0060] Take by weight percentage polylactic acid resin (number average molecular weight is 100,000, Natureworks4032D, LD mixed type polylactic acid, L type is 97%, D type is 3%) 95.0%, glycidyl methacrylate 3.0%, peroxide 2.0% of tert-butyl benzoate, after mixing uniformly, is used as a mixed material; the mixed material is added into a twin-screw extruder to melt and extrude, and granulated to obtain a granular product (i.e. glycidyl methacrylate grafted polylactic acid copolymer Material). Among them, the temperature of each section of the mixed material in the twin-screw extruder is respectively: the temperature of the feeding section is 165°C, the temperature of the compression section is 175°C, the temperature of the metering section is 180°C, the temperature of the head is 185°C, and the speed of the twin-screw extruder is 300 rpm. The molecular weight, molecular weight distribution and epoxy value of the sample are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com