Preparation method and application of poly-glycidyl methacrylate interosculated porous material

A polymethacrylic acid, glycidyl ester technology, applied in application, e-liquid filter, food science and other directions, can solve the problem of reducing the amount of phenol released, and achieve the effect of reducing the amount of phenol released, improving the adsorption rate, and high specific surface area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

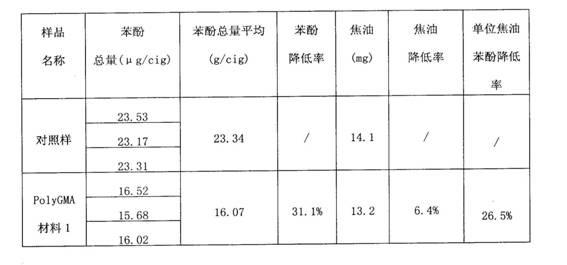

[0025] First configure the oil phase: take 2ml of GMA, 3ml of ethylene glycol dimethacrylate, 5ml of toluene, and 1g of SPAN 80 to prepare the oil phase; then configure the water phase: take 56ml of water, 0.5g of calcium chloride and 0.15g of potassium persulfate to prepare the water phase; then under high-speed stirring, the water phase was slowly added to the oil phase to form a high internal phase emulsion, and then it was put into a 50-60°C oven for 24 hours of reaction; the resulting The solid product was extracted with water and isopropanol for 24 hours respectively, and dried in a vacuum oven to obtain PolyGMA material 1.

[0026] PolyGMA material 1 is used as a compound filter additive material, the additive amount is 15mg / cig, and the cigarette without any filter modified material is used as a control sample, and the cigarette smoking test is carried out on a smoking machine according to the standard smoking conditions, and according to The standard YC / T255-2008 is u...

Embodiment 2

[0031] First configure the oil phase, take 2ml of GMA, 3ml of trimethylolpropane trimethacrylate, 5ml of toluene, and 1g of SPAN 80 to prepare the oil phase; then configure the water phase: take 56ml of water, 0.5g of chlorinated Calcium and 0.15g of potassium persulfate are formulated into the water phase; then under high-speed stirring, the water phase is slowly added to the oil phase to form a high internal phase emulsion, and then it is put into a 50-60°C oven for 24 hours of reaction; The resulting solid product was extracted with water and isopropanol for 24 hours, and dried in a vacuum oven to obtain PolyGMA material 2.

[0032] PolyGMA material 2 is used as a compound filter additive material, and the additive amount is 15mg / cig (stick), and the cigarette without any filter modified material is used as a control sample, and the cigarette smoking test is carried out on a smoking machine according to standard smoking conditions , and perform the detection of phenol relea...

Embodiment 3

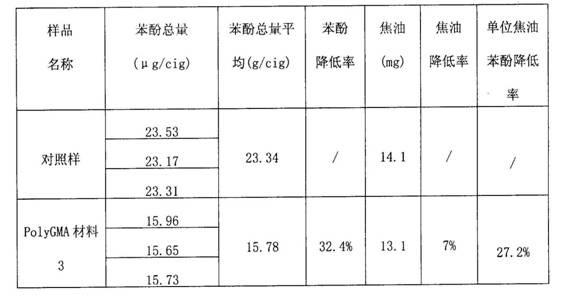

[0038]First configure the oil phase; take 3ml of GMA, 2ml of trimethylolpropane trimethacrylate, 5ml of xylene, and 1g of TWEEN 60 to prepare the oil phase; then configure the water phase: take 56ml of water, 0.5g of chlorine Sodium chloride and 0.15g of potassium persulfate are prepared into the water phase; under high-speed stirring, the water phase is slowly added to the oil phase to form a high internal phase emulsion, which is then placed in an oven at 50-60°C for 24 hours of reaction. The obtained solid product was extracted with water and isopropanol for 24 hours respectively, and dried in a vacuum oven to obtain PolyGMA material 3 .

[0039] PolyGMA material 3 is used as a composite filter additive material, the additive amount is 15mg / cig, and the cigarette without any filter modified material is used as a control sample, and the cigarette smoking test is carried out on a smoking machine according to the standard smoking conditions, and according to The standard YC / T2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com