Method for preparing porous carbon through co-pyrolysis of petroleum coke and oily sludge

A sludge co-pyrolysis and petroleum coke technology, applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve problems such as difficulty, long process, and large gap, and achieve increased surface activity, high adsorption performance, The effect of developed pores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

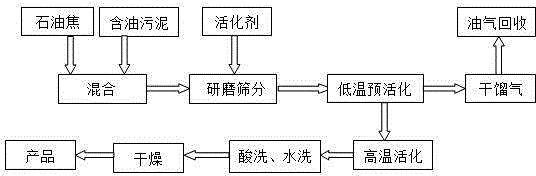

Image

Examples

Embodiment 1

[0058] The method for preparing porous carbon by co-pyrolysis of petroleum coke and oily sludge uses petroleum coke and oily sludge as raw materials, and comprises the following steps in sequence:

[0059] (1) Pre-dry the oily sludge to remove part of the moisture, so that the moisture content of the oily sludge is less than 10%;

[0060] The sludge pre-drying can be carried out in an oven, the temperature is controlled at 110°C, and the drying time is 24 hours. At this time, most of the water in the oily sludge is converted into water vapor;

[0061] The water content of oily sludge is 47.0%, the oil content is 35.80%, and the solid content is 17.40%, all of which are mass fractions;

[0062] (2), the oily sludge obtained in step 1 is mixed with petroleum coke in a mass ratio of 1:1;

[0063] The petroleum coke used is a black solid product produced by cracking and coking in the coking unit during the petroleum refining process. Its ash content is 0.66%, volatile content is ...

Embodiment 2

[0077] The method for preparing porous carbon by co-pyrolysis of petroleum coke and oily sludge uses petroleum coke and oily sludge as raw materials, and comprises the following steps in sequence:

[0078] (1) Pre-dry the oily sludge to remove part of the moisture, so that the moisture content of the oily sludge is less than 10%;

[0079] The sludge pre-drying can be carried out in an oven, the temperature is controlled at 110°C, and the drying time is 24 hours. At this time, most of the water in the oily sludge is converted into water vapor;

[0080] The water content of oily sludge is 47.0%, the oil content is 35.80%, and the solid content is 17.40%, all of which are mass fractions;

[0081] (2), the oily sludge obtained in step 1 is mixed with petroleum coke in a mass ratio of 1:3;

[0082] The petroleum coke used is a black solid product produced by cracking and coking in the coking unit during the petroleum refining process. Its ash content is 0.66%, volatile content is ...

Embodiment 3

[0096] The method for preparing porous carbon by co-pyrolysis of petroleum coke and oily sludge uses petroleum coke and oily sludge as raw materials, and comprises the following steps in sequence:

[0097] (1) Pre-dry the oily sludge to remove part of the moisture, so that the moisture content of the oily sludge is less than 10%;

[0098] The sludge pre-drying can be carried out in an oven, the temperature is controlled at 110°C, and the drying time is 24 hours. At this time, most of the water in the oily sludge is converted into water vapor;

[0099] The water content of oily sludge is 47.0%, the oil content is 35.80%, and the solid content is 17.40%, all of which are mass fractions;

[0100] (2), the oily sludge obtained in step 1 is mixed with petroleum coke in a mass ratio of 1:1;

[0101] The petroleum coke used is a black solid product produced by cracking and coking in the coking unit during the petroleum refining process. Its ash content is 0.66%, volatile content is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| iodine adsorption value | aaaaa | aaaaa |

| iodine adsorption value | aaaaa | aaaaa |

| iodine adsorption value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com