Catalyst for reforming methane and carbon dioxide to prepare synthetic gas as well as preparation method and application thereof

A carbon dioxide and synthesis gas technology, which is applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, hydrogen/syngas production, etc. and other problems, to achieve the effect of good catalytic activity and stability, good catalytic performance, and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

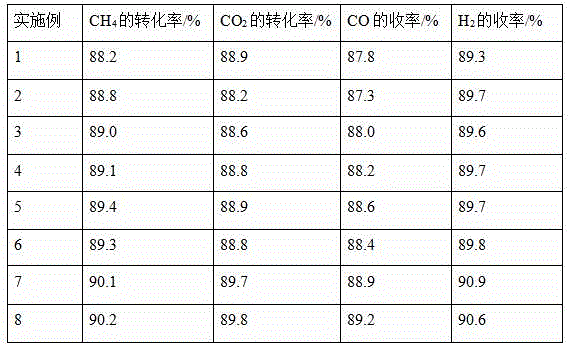

Examples

Embodiment 1

[0035] Lignite and moso bamboo were carbonized at 600°C in the absence of air, and the carbonization time was 5 hours. The obtained lignite material B and moso bamboo charcoal material C are crushed respectively to obtain carbon materials with particle diameters ranging from 100 mesh to 300 mesh. Take 100g of lignite material and 10g of moso bamboo charcoal material, that is, mix the two at a ratio of 1:0.1 to obtain D, and add binder asphalt. The amount of asphalt is 35% of the total mass of B and C. Carbonize again to obtain composite carbon material E, then crush the obtained mixed carbon material E, and sieve composite carbon material F with a particle size of 0.1mm-3mm. Then, water vapor was introduced for activation, the activation temperature was 800°C, and the activation time was 30 minutes, and then dilute ammonia water was used for activation, the concentration of ammonia water was 10 wt %, the activation temperature was 600°C, and the activation time was 100 minutes...

Embodiment 2

[0038] Lignite and moso bamboo were carbonized at 600°C in the absence of air, and the carbonization time was 5 hours. The obtained brown coal material B and moso bamboo charcoal material C are crushed respectively to obtain carbon materials with a particle size of 100 mesh to 300 mesh. Take lignite material 100g, moso bamboo charcoal material 100g, mix the two at a ratio of 1:1 to obtain D, and add binder asphalt, the amount of asphalt is 35% of the total mass of B and C, at 900 ° C Carbonize again to obtain composite carbon material E, then crush the obtained mixed carbon material E, and sieve composite carbon material F with a particle size of 0.1mm-3mm. Then pass through carbon dioxide to activate, the activation temperature is 800°C, the activation time is 30min, and then activated with dilute ammonia water, the concentration of ammonia water is 10 wt%, the activation temperature is 700°C, and the activation time is 100min. A composite activated carbon G consisting of li...

Embodiment 3

[0041] Lignite and moso bamboo were carbonized at 600°C in the absence of air, and the carbonization time was 5 hours. The obtained lignite material B and moso bamboo charcoal material C are crushed respectively to obtain carbon materials with particle diameters ranging from 100 mesh to 300 mesh. Take lignite material 100g, moso bamboo charcoal material 200g, mix the two according to the ratio of 1:2 to obtain D, and add binder asphalt, the amount of asphalt is 35% of the total mass of B and C, at 850 ° C Carbonize again to obtain composite carbon material E, then crush the obtained mixed carbon material E, and sieve composite carbon material F with a particle size of 0.1mm-3mm. Then pass through water vapor to activate, the activation temperature is 800°C, the activation time is 30min, and then activated with dilute ammonia water, the concentration of ammonia water is 10 wt%, the activation temperature is 700°C, and the activation time is 100min. A composite activated carbon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com