Method for preparing activated carbon powder with lignin from alkaline papermaking black liquor

A technology for powdered activated carbon and papermaking black liquor, applied in chemical instruments and methods, non-metallic elements, carbon compounds, etc., can solve the problems of reduced micropore volume and surface area, reduced specific surface area of activated carbon, insufficient lignin carbonization, etc. , to achieve the effect of developed pores, strong adsorption, and waste recycling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

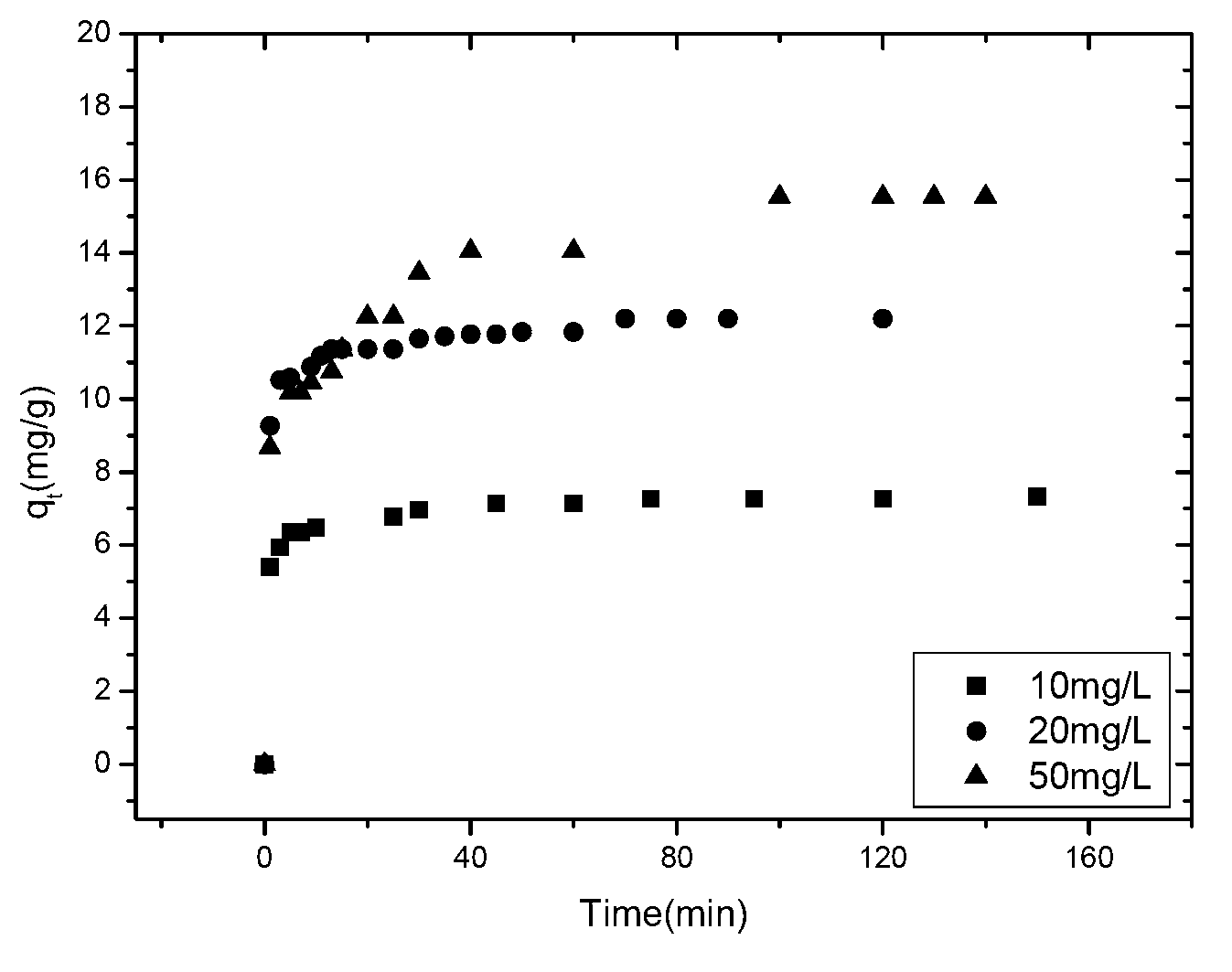

[0034] A method for preparing powdered activated carbon from lignin from alkaline papermaking black liquor, the steps are as follows:

[0035] 1. Use acid analysis to extract lignin from alkaline papermaking black liquor and purify the extracted lignin to remove possible inorganic substances, such as silicon dioxide, to reduce the impact on the subsequent carbonization or activation process. The extraction and purification steps are as follows: pass carbon dioxide gas into the alkaline papermaking black liquor, then add 1mol / L sulfuric acid for pickling, the lignin is precipitated under acidic conditions, filter, separate the precipitate from the black liquor, and dry the precipitate Dry, extract crude lignin; the extracted crude lignin is dissolved in water, the ratio of crude lignin to water is 1:3, add 1mol / L hydrochloric acid solution, the addition amount is 10ml / g lignin, adjust the pH to 2 , soaked for 24 hours, suction filtered, washed with deionized water until the pH ...

Embodiment 2

[0043] A method for preparing powdered activated carbon from lignin from alkaline papermaking black liquor, the steps are as follows:

[0044] 1, lignin extraction, with embodiment 1.

[0045] 2. Carbonization of lignin

[0046] The lignin was pulverized and passed through a 40-mesh sieve; the lignin under the sieve was put into a porcelain crucible, then placed in a resistance furnace, heated to 300°C, and carbonized for 100 minutes.

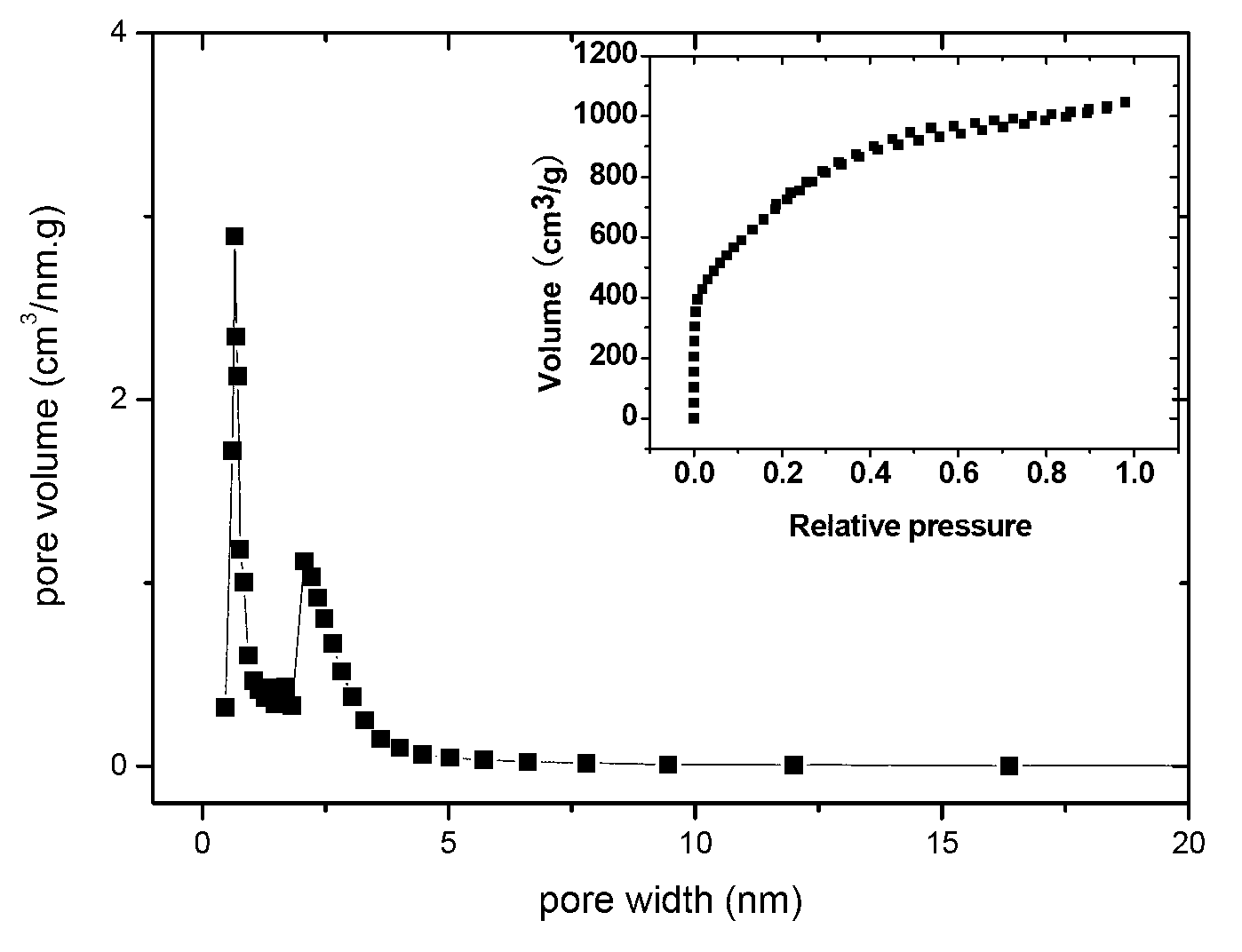

[0047] 3. Activation

[0048] Take the carbonized lignin and add it to the crucible, then add KOH with a mass fraction of 85%, and stir while adding. The mass ratio of lignin to KOH is 1:4. Place the crucible in an ultrasonic water bath for 35 minutes, 105°C Dry the mixture of lignin and potassium hydroxide in a tube heating furnace for heating and activation for 1 hour. The temperature in the tube heating furnace is 700 ° C. Stop heating and cool to room temperature under nitrogen atmosphere. The final product is taken out; washed with dilu...

Embodiment 3

[0050] A method for preparing powdered activated carbon from lignin from alkaline papermaking black liquor, the specific steps are as follows:

[0051] 1, lignin extraction, with embodiment 1.

[0052] 2. Carbonization of lignin

[0053] Take the lignin and pulverize it, pass through a 40-mesh sieve, put the lignin under the sieve into a porcelain crucible, then place it in a resistance furnace, heat up to 400°C, and carry out carbonization treatment for 80 minutes.

[0054] 3. Activation of lignin, add charred lignin into the crucible, then add KOH with a mass fraction of 85%, stir while adding, the mass ratio of lignin to KOH is 1:2, put the crucible in ultrasonic Ultrasound in a water bath for 35 minutes, and dry at 105°C; place the dried lignin and potassium hydroxide mixture in a tube heating furnace for heating and activation for 2 hours, and the temperature in the tube heating furnace is 650°C, stop heating , cooled to room temperature under a nitrogen atmosphere, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com