Method for preparing active carbon by taking biomass pyrolytic carbon as raw material

A technology for preparing activated carbon and biomass pyrolysis. It is applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc. It can solve the problem of not much biomass pyrolysis carbon, and achieve developed pores, increased added value, and high adsorption value. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

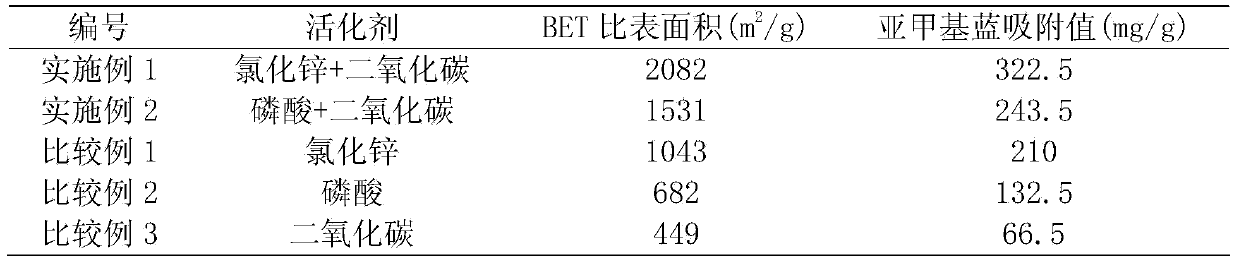

Embodiment 1

[0023] The pyrolytic charcoal obtained by rapid pyrolysis of Chinese fir is washed with distilled water, stirred, left standing, and precipitated to remove the gravel contained therein. Take the pyrolytic charcoal floating on the upper layer, dry it, and pulverize the dried pyrolytic charcoal, pass through a 60-mesh sieve, and set aside. An aqueous solution of zinc chloride is prepared, and the aqueous solution is mixed with pyrolytic carbon, stirred and impregnated. The mass ratio of pyrolytic carbon to zinc chloride is 1:2. The mixed solution was dried in an oven for 6 hours, and the temperature was controlled at 100°C. Then, the carbon powder is placed in a heating furnace to raise the temperature for activation, and nitrogen protection is introduced during the heating process. After the desired temperature was reached, the nitrogen was turned off and carbon dioxide was introduced at a flow rate of 0.05 L / min. The activation temperature is 500°C, and the activation time i...

Embodiment 2

[0026] The method is similar to Example 1, except that the chemical activator is replaced by phosphoric acid, and the mass ratio of pyrolytic charcoal and phosphoric acid is changed to 1:10, and the activation temperature is changed to 800°C. The pyrolytic charcoal obtained by rapid pyrolysis of Chinese fir is washed with distilled water, stirred, left standing, and precipitated to remove the gravel contained therein. Take the pyrolytic charcoal floating on the upper layer, dry it, and pulverize the dried pyrolytic charcoal, pass through a 60-mesh sieve, and set aside. An aqueous solution of phosphoric acid is prepared, and the aqueous solution is mixed with pyrolytic carbon, stirred and impregnated. The mass ratio of pyrolytic carbon to phosphoric acid is 1:10. The mixed solution was dried in an oven for 6 hours, and the temperature was controlled at 100°C. Then, the carbon powder is placed in a heating furnace to raise the temperature for activation, and nitrogen protection...

Embodiment 3

[0029] The method is similar to that of Example 1, except that the chemical activator is replaced by potassium hydroxide, and the flow rate of carbon dioxide is changed to 2L / min. The pyrolytic charcoal obtained by rapid pyrolysis of Chinese fir is washed with distilled water, stirred, left standing, and precipitated to remove the gravel contained therein. Take the pyrolytic charcoal floating on the upper layer, dry it, and pulverize the dried pyrolytic charcoal, pass through a 60-mesh sieve, and set aside. An aqueous solution of potassium hydroxide is prepared, and the aqueous solution is mixed with pyrolytic charcoal, stirred and impregnated. The mass ratio of pyrolytic charcoal to potassium hydroxide is 1:2. The mixed solution was dried in an oven for 6 hours, and the temperature was controlled at 100°C. Then, the carbon powder is placed in a heating furnace to raise the temperature for activation, and nitrogen protection is introduced during the heating process. After th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com