Method for preparing novel oil production wastewater adsorbent by utilizing oil sludge pyrolysis residue

A technology of oil production wastewater and adsorbent, which is applied in chemical instruments and methods, solid waste removal, adsorption water/sewage treatment, etc., can solve problems such as fragility, different pore sizes, and dissolved organic matter, and achieve large specific surface area, Good chemical properties and well-developed pores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1: Taking the method of preparing a novel oil production wastewater adsorbent by using oil sludge pyrolysis residue at one time as an example, the present invention will be further described in detail.

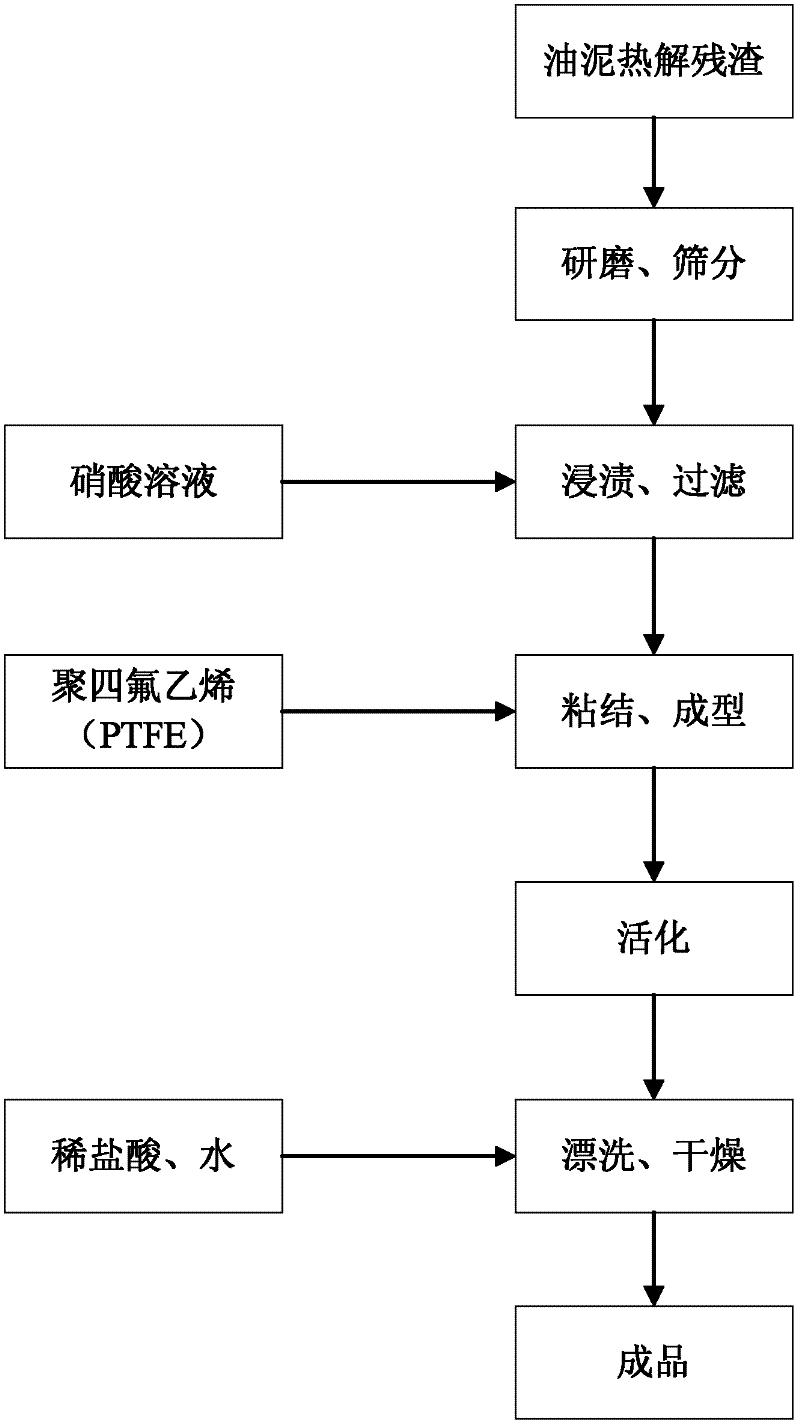

[0022] A method for preparing a novel oil recovery wastewater adsorbent by using oil sludge pyrolysis residues, including grinding and screening oil sludge pyrolysis residues, acid impregnation treatment, rinsing to neutrality, mixing with polytetrafluoroethylene (binder), cold pressing, and carbonization The specific process of carbonization, rinsing and drying in the furnace is as follows:

[0023] Step 1: Grinding and screening the sludge pyrolysis residue. The material used is the residue after high temperature pyrolysis of oily sludge composed of mineral oil, minerals and water produced in the original crude oil exploitation, gathering and refining process. The sludge pyrolysis residue particles are ball milled and passed through a 100-mesh screen to ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| micropore | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com