Preparation method of ionic liquid type hydroxylamine salt

A technology of ionic liquid and hydroxylamine salt, which is applied in the preparation of sulfonate, organic chemistry, etc., can solve the problem of difficult recovery of inorganic acid, and achieve the effect of rich variety, environmental friendliness and stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

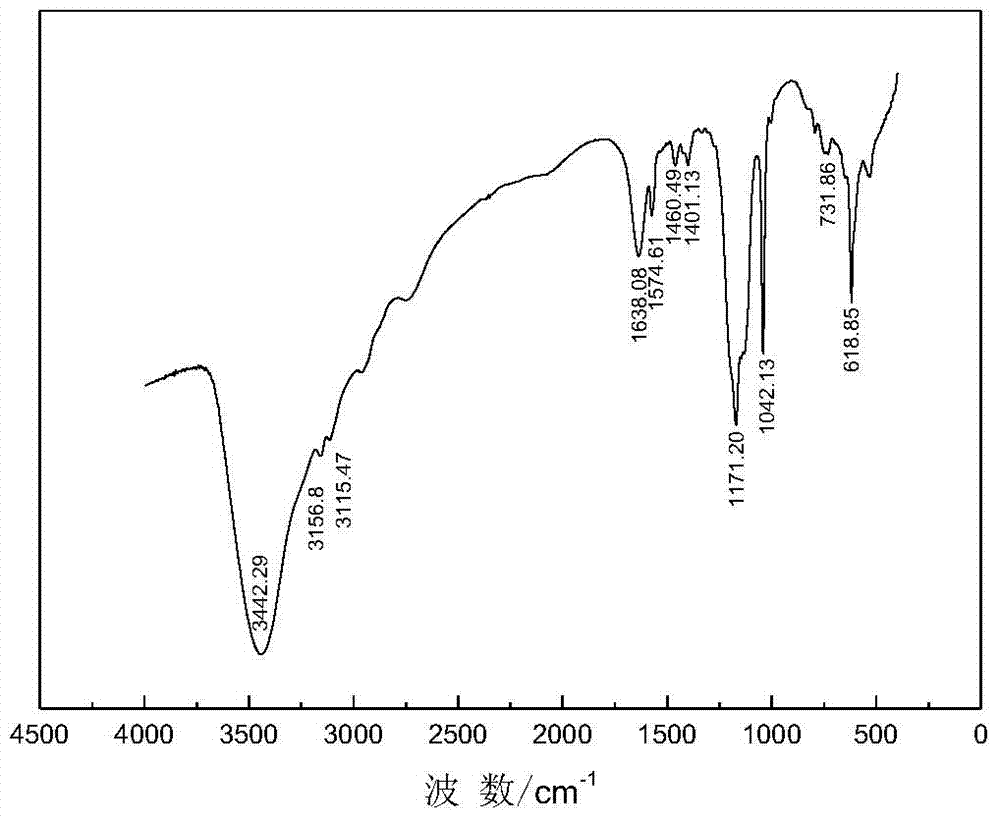

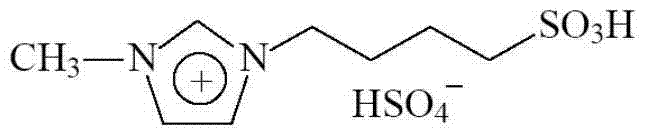

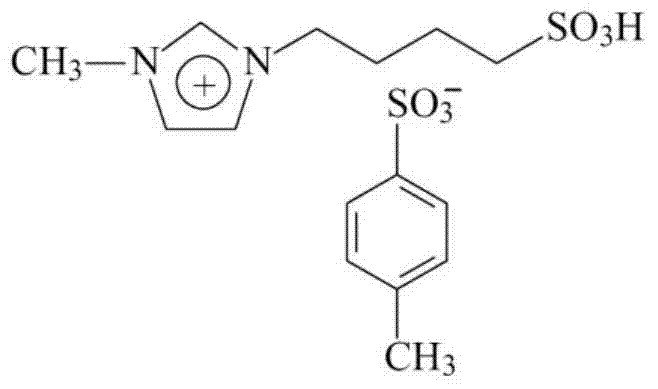

Image

Examples

Embodiment 1

[0030] Refer to the synthesis method reported in the literature (US5266290, 1993): Weigh 41.0g of hydroxylamine sulfate (0.5mol in terms of hydroxylamine) and dissolve it in 100ml of distilled water (5.56mol), and place the above aqueous solution of hydroxylamine sulfate in a low-temperature constant temperature reactor at -5°C 40g of NaOH solution with a mass percentage of 50% was added dropwise under stirring (among them, the alkali was 0.5mol in terms of hydroxide radicals, and the water was 1.11mol); after the addition was complete, the stirring was continued for 0.1h, and the reaction solution was separated by filtration to obtain The filtrate was 100ml, and the filter cake was washed with 40ml of distilled water, and the combined filtrate and lotion were 140ml in total; in the above combined filtrate and lotion, 0.105g of stabilizer ascorbic acid (0.08% by weight) was added, and the pressure was reduced at 52°C Distill (0.098MPa) and distill for 1h. During this process, t...

Embodiment 2

[0032] Weigh 43.0g of hydroxylamine sulfate (0.52mol in terms of hydroxylamine) and dissolve it in 100ml of distilled water (5.56mol), put the above aqueous solution of hydroxylamine sulfate in a low temperature and constant temperature reactor at 0°C, and add dropwise under stirring a mass percentage of 50% 40g of NaOH solution (among them, the alkali is 0.5mol in terms of hydroxide radicals, and water is 1.11mol); after the addition, continue to stir for 0.1h, filter and separate the reaction solution to obtain 110ml of filtrate, wash the filter cake with 25ml of distilled water, combine the filtrate and washing A total of 135ml of liquid solution; in the above combined filtrate and lotion, add 0.202g of stabilizer ascorbic acid (0.15% by weight), and distill under reduced pressure (0.096MPa) at 54°C for 1.5h, during which the distillate Cool with ice water all the time to obtain 97ml of hydroxylamine aqueous solution distillate. The fraction was determined by the potassium ...

Embodiment 3

[0034]Weigh 41.0g of hydroxylamine sulfate (0.5mol in terms of hydroxylamine) and dissolve it in 70ml of distilled water (3.89mol), put the above aqueous solution of hydroxylamine sulfate in a low temperature and constant temperature reactor at 5°C, and add dropwise under stirring with a mass percentage of 50% 40g of NaOH solution (among them, the alkali is 0.5mol in terms of hydroxide radicals, and water is 1.11mol); after the addition, continue to stir for 0.2h, filter and separate the reaction solution to obtain 75ml of filtrate, wash the filter cake with 25ml of distilled water, combine the filtrate and washing A total of 100ml of solution; in the above combined filtrate and lotion, add 0.102g of stabilizer ascorbic acid (0.10% by weight), and distill under reduced pressure (0.095MPa) at 56°C for 2h, during which the distillate is always Cool with ice water to obtain 50ml of hydroxylamine aqueous solution distillate. The fraction was determined by the potassium permanganat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com