One-step method for producing dephenolized cotton protein

A cotton protein and dephenolization technology, which is applied in vegetable protein processing, fat production, fat oil/fat refining, etc., can solve the problems of many equipment, high solvent consumption, and high operating cost, and achieves the goal of using less equipment, short process route, The effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

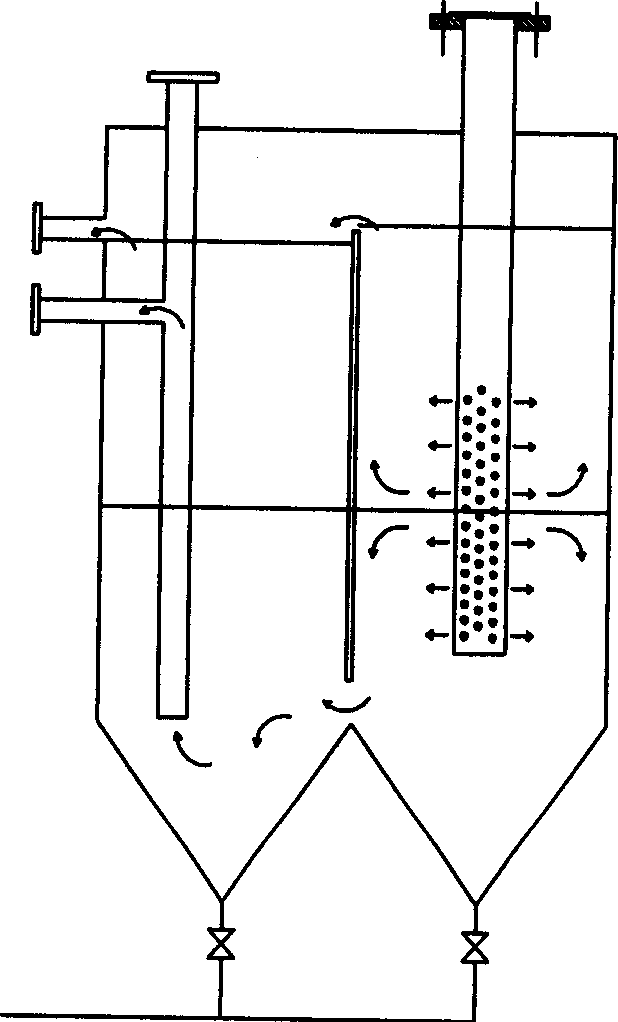

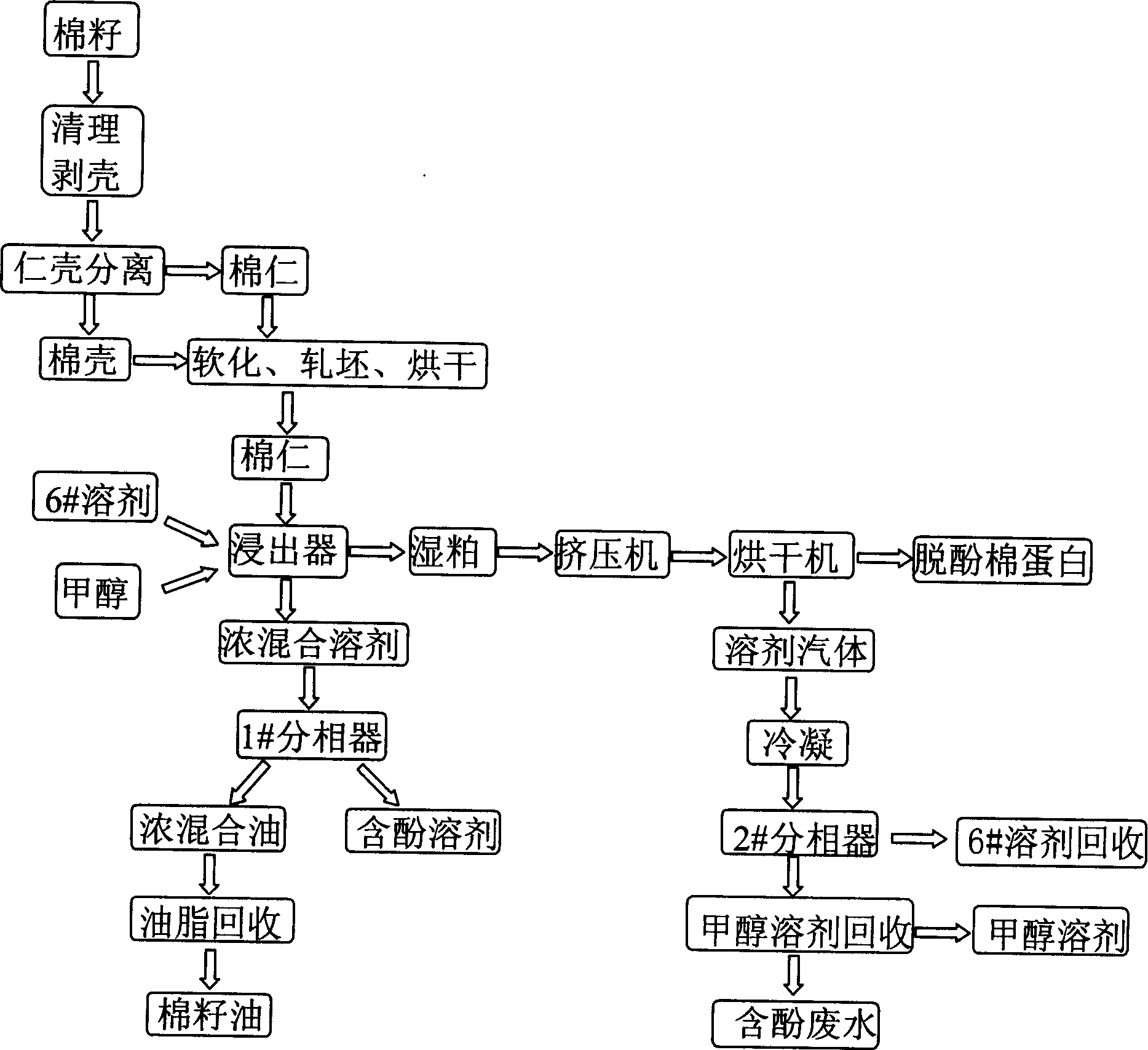

[0027] The present invention adds 6# solvent and methanol two kinds of solvents simultaneously in the extractor of cottonseed kernel, and mixes two kinds of solvents by mixer; The phenol is leached and extracted, and after the solvent is repeatedly circulated, all the oil and gossypol in the cottonseed are finally extracted.

[0028] After the cottonseed kernel is extracted by solvent, the amount of oil and gossypol contained is already very low, and it is dephenolized cotton protein after drying.

[0029] The mixed solvent containing oil and gossypol is cooled to 25°C and enters the 1# phase separator for phase separation. The solvent containing oil is the light phase and is discharged from the top; the solvent containing gossypol is the heavy phase and is discharged from the bottom.

[0030] The light phase solvent can be recovered to obtain cottonseed oil; the heavy phase phenolic solvent and the solvent gas condensate discharged from the dryer enter the 2# phase separator ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com