Method for producing pure cotton non-woven fabrics for life and hygiene

A production method and non-woven technology, which are applied in non-woven fabrics, textiles and papermaking, bleaching products, etc., can solve the problems of long bleaching process time, low work efficiency, and high water consumption, saving manpower, saving operating costs, The effect of preventing yellow and white unevenness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

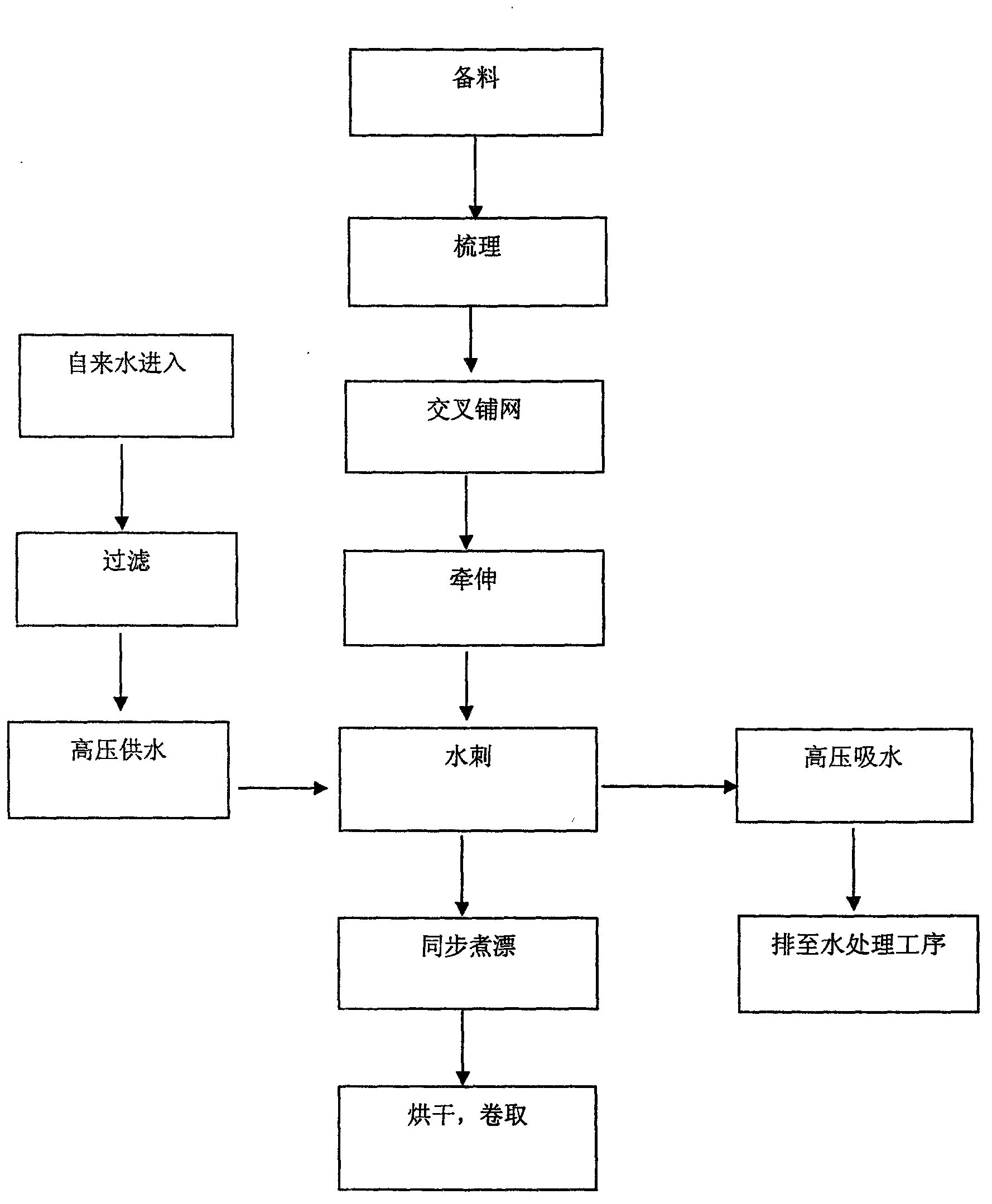

[0019] Describe concrete processing step of the present invention in detail below in conjunction with process flow chart:

[0020] 1. Carding: Under the environmental conditions of temperature between 15°C-25°C, relative humidity between 15°-70°, and equipped with a dust removal system, the prepared cotton is carded with an opening and cleaning machine and a carding machine , open the cotton bundles to make single fibers; and remove the impurities and short fibers in the raw cotton, the removal efficiency can reach 95%-99%, and finally the impurities in the carding sliver are only 0.05%-0.3% Then, the cotton fibers are mixed and carded, and the cotton fibers are mixed longitudinally along the cotton flow in the process of coagulating the cotton fibers in the doffer, and then the cotton fibers are mixed horizontally along the cotton flow in the process of forming a web, and finally carded to allow the cotton fibers The fiber web is arranged and positioned along the direction. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com