Method for preparing nanometer nitrified beta-cyclodextrin fiber by electrostatic spinning

A technology of electrospinning and cyclodextrin, which is applied to the chemical characteristics of fibers, attacking equipment, textiles and papermaking, etc., can solve the problem that the large specific surface area, high surface energy and high surface activity of nanoparticles cannot be fully utilized, and the actual use effect of nanoparticles Problems such as lack of improvement and large surface energy of nanoparticles can achieve the effects of short preparation cycle, broad application and simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

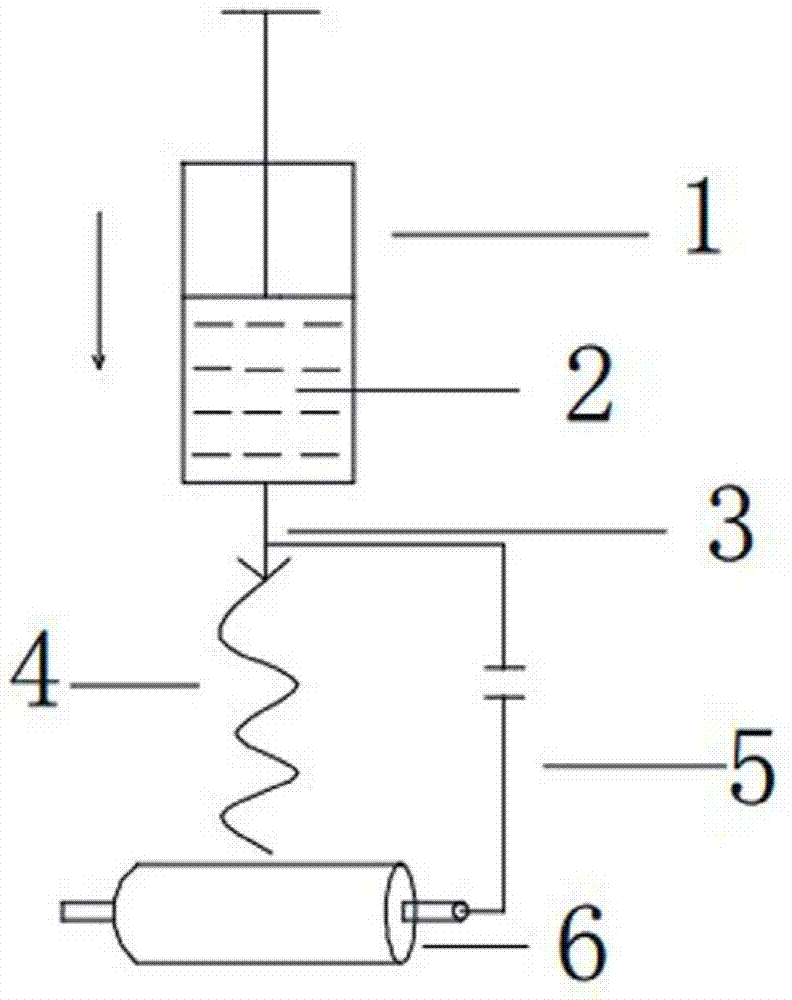

[0024] Such as figure 1 as shown, figure 1 A schematic diagram of the structure of the electrospinning device used in this example is shown, the electrospinning device is as figure 1 As shown, it includes: a syringe 1, a receiver 6, an injection needle 3 is arranged at the lower end of the syringe, and a high-voltage power supply 5 is arranged between the syringe 1 and the receiver to provide high-voltage static electricity; when in use, the electrospinning solution 2 is loaded in the syringe 1, the electrospinning solution is injected through the injection needle 3 of the syringe 1, and the spinning 4 is formed under the action of high-voltage electrostatic, and the receiver 6 receives the spinning 4. The method for preparing nano-nitrated β-cyclodextrin fibers by electrospinning in this embodiment includes the following steps: (1) preparing an electrospinning solution: at room temperature, mix nitrated β-cyclodextrins with a mixed solvent to prepare An electrospinning solu...

Embodiment 2

[0029] The method for preparing nano-nitrated β-cyclodextrin fibers by electrospinning in this embodiment includes the following steps: (1) preparing an electrospinning solution: at room temperature, add nitrated β-cyclodextrins to acetone and N, N -Dimethylformamide acetone and N,N-dimethylacetamide can be prepared in a volume ratio of 4:0.5-4:2. The specific embodiment is that acetone and N,N-dimethylacetamide are 2:1 by volume, in the mixed solvent of composition, prepare 20 milliliters of concentrations and be the electrospinning solution of 20%, in the electrospinning solution include Nanoparticles: The mass ratio of nitrated β-cyclodextrin to nanoparticles is 10:0-7:3, which can better improve the propellant combustion performance. Nano particles include: nano metal particles, nano metal oxide particles. Nano metal particles include: one or more of magnesium, aluminum, silicon, copper, beryllium and boron. Nano metal oxide particles include: ferric oxide, iron oxide, t...

Embodiment 3

[0034] The method for preparing nano-nitrated β-cyclodextrin fibers by electrospinning in this embodiment includes the following steps: (1) preparing an electrospinning solution: at room temperature, add nitrated β-cyclodextrins to acetone and N, N -Dimethylformamide acetone and N,N-dimethylacetamide can be prepared in a volume ratio of 4:0.5-4:2. The specific embodiment is that acetone and N,N-dimethylacetamide are 2:1 by volume, in the mixed solvent of composition, prepare 20 milliliters of concentrations and be the electrospinning solution of 20%, in the electrospinning solution include Nanoparticles; the mass ratio of nitrated β-cyclodextrin to nanoparticles is 10:0-7:3, which can better improve the combustion performance of the propellant. Nano particles include: nano metal particles, nano metal oxide particles. Nano metal particles include: one or more of magnesium, aluminum, silicon, copper, beryllium and boron. Nano metal oxide particles include: ferric oxide, iron o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com