Wire tightening device for low-voltage stringing and stringing method

A wire-strapping and wire-tightening technology, applied in the direction of overhead lines/cable equipment, etc., can solve the problems of wire sag that does not meet the national standard, no wire-carrying vehicles and drones, and inability to bear equipment costs, so as to achieve a small occupied space. , low cost, low maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

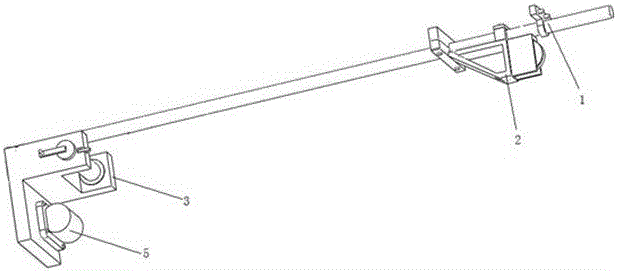

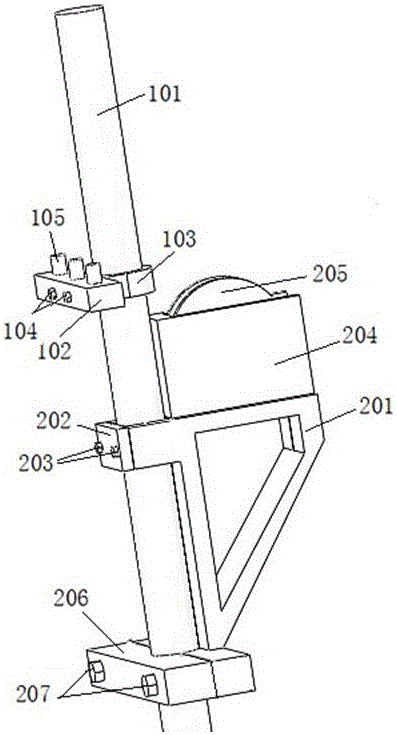

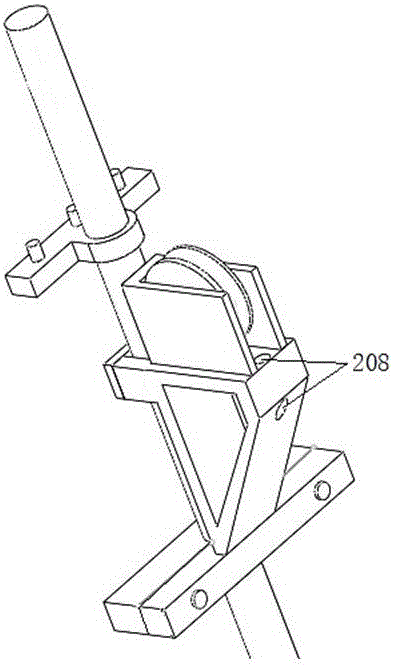

[0033] see Figure 1-8A kind of tensioning device for low-voltage stringing includes a utility pole part 1, a device part 2 on the pole, a ground device part 3, a steel wire guide rope 4 and a power part 5, wherein the utility pole part 1 includes a utility pole 101, a cross arm 102, U-shaped hoop 103, nut 104, porcelain bottle 105; device part 2 on the pole comprises trapezoidal support 201, small fixed plate 202, first screw 203, pulley support 204, pulley 205, large fixed plate 206, second screw 207 and wire Hole 208; Ground device part 3 comprises L-shaped base 301, reel support 302, ball bearing 303, reel 304, crank handle 305, gear 306, rectangular iron sheet 307, iron sheet fixed shaft 308, reel fixed hole 309 and Large pulley 310; the bottom of the utility pole 101 is buried in the ground or poured in cement concrete, and the utility pole 101 is perpendicular to the ground; The cross arm 102 is fixed to the top of the utility pole 101 through a U-shaped hoop 103 and a...

Embodiment 2

[0035] A method for stringing using the low-voltage stringing device, comprising the following steps:

[0036] a, at first the small fixed plate 202 and the upper end of the trapezoidal support 201 are connected with the first screw 203, the lower end of the large fixed plate 206 and the trapezoidal support 201 is connected with the second screw 207, and the trapezoidal support 201 is enclosed within the utility pole 101, The small fixed plate 202, the large fixed plate 206 and the trapezoidal support 201 can move up and down along the direction of the utility pole 101;

[0037] b. Pull the trapezoidal bracket 201 to the top of the utility pole 101 and below the cross arm 102, and use the first screw 203 and the second screw 207 to fix the trapezoidal bracket 201 to the top of the utility pole 101 through the small fixing plate 202 and the large fixing plate 206 ;

[0038] c. Fix one end of the steel wire rope 401 of the steel wire guide rope 4 on the reel fixing hole 309, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com