Simple buried installation fixed bracket and installation method thereof

A fixed frame and simple technology, applied to the simple buried installation fixed frame and its installation field, can solve the problems of high installation difficulty, low installation efficiency, large labor cost, etc., to simplify installation steps, improve installation efficiency, and reduce installation. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

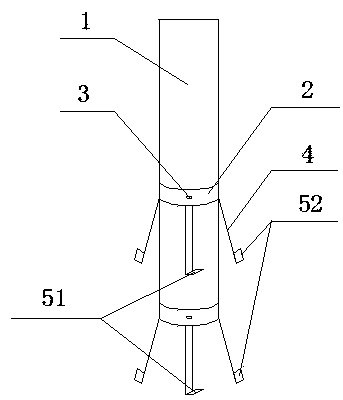

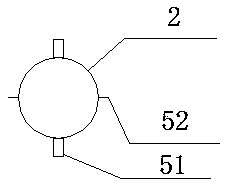

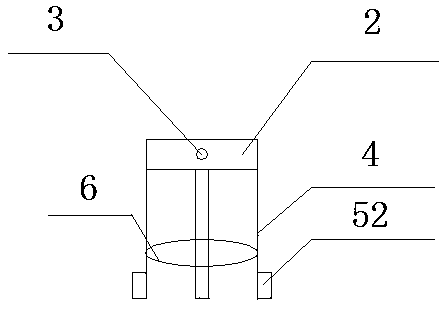

[0019] In this example, refer to Figure 1 to Figure 8 As shown, a simple buried installation fixture and its installation method include a column body 1, and a mounting ring 2 set on the outside of the column body 1, and a mounting hole 3 set in the middle of the side of the mounting ring 2, and setting The support rod 4 on the lower edge of the mounting ring 2, and the upper and lower fixed feet 51 or rotating fixed feet 52 arranged at the end of the support rod 4.

[0020] Wherein, each support rod 4 bounces at an angle of 10° to 60°, and multiple support rods 4 form a plurality of triangles with different angles when they bounce off, so as to ensure that the column 1 is firmly buried in the soil.

[0021] Wherein, the shape of the upper and lower fixed feet 51 is placed horizontally and fixedly connected with the support rod 4, so as to prevent the cylinder 1 from being lifted up by people, which is safe and stable; the shape of the rotating fixed foot 52 is placed vertica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com