Concrete mixing and filling pump truck for mines

A concrete and mining technology, applied in mixing plants, clay preparation devices, mixing operation control, etc., can solve the problems of total installation length, large workload, inconvenient installation and movement, and achieve simple operation and small construction area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

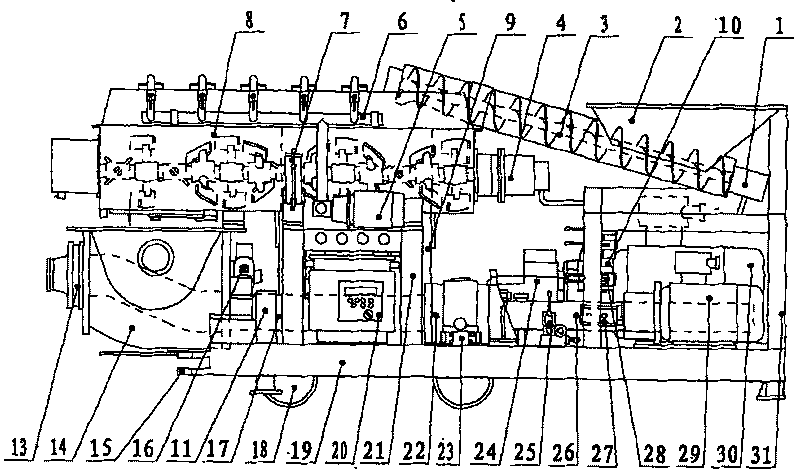

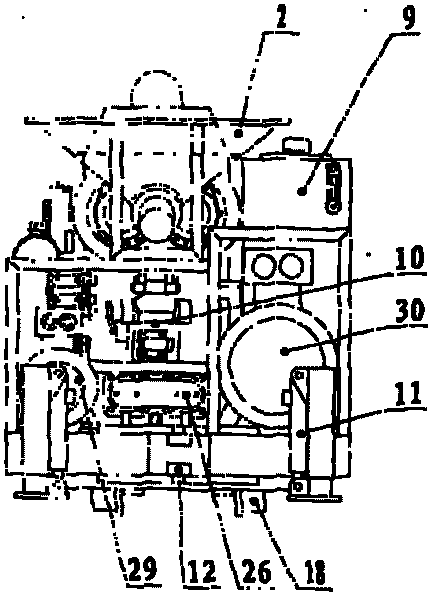

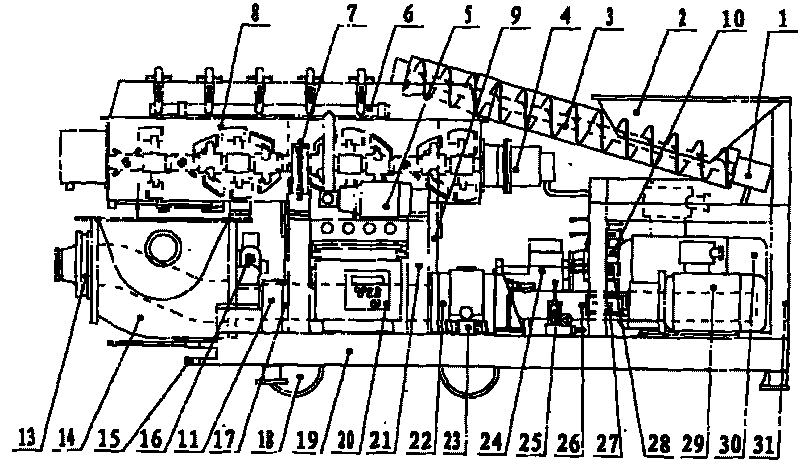

[0018] Such as figure 1 , figure 2 Shown: A mining concrete mixing and filling pump truck includes: a concrete mixed dry material feeder 3, a mixer 8, a water supply system 6, a finished concrete delivery system, a hydraulic power system, and a control system 20. It is characterized in that: all the devices mentioned above are installed on the frame 19; the lower end of the frame 19 is provided with a track wheel 18 matching the track, and the front and rear ends of the frame 19 are respectively provided with a front traction ring 15 and a rear The four corners of the traction ring 12 and the frame 19 are provided with four outrigger cylinders 11; the hydraulic power system includes a delivery hydraulic pump set 24 and a mixing hydraulic pump set 27.

[0019] The working principle and operation method of this machine: put the mixed concrete dry material into the hopper 2, drive the screw feeder 3 through the feeding motor 1 to convey the dry material to the mixer 8 at a uniform ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com