Magnetite beneficiation method

A mineral processing method and magnetite technology, applied in the direction of solid separation, etc., can solve the problems that the mineral processing process cannot meet the requirements of the mineral processing process conditions, the magnetite powder ore separation and enrichment ratio is low, and the grade of the separation concentrate is limited. , to achieve the effect of increasing the added value of technology, saving transportation costs and reducing mineral processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

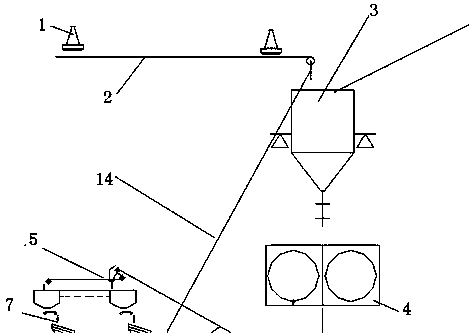

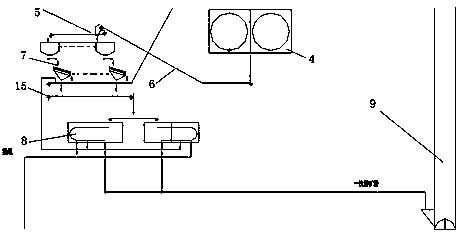

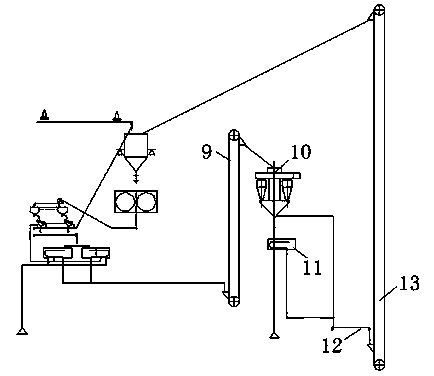

[0029] Embodiment of the present invention is described below in conjunction with accompanying drawing, embodiment does not constitute limitation of the present invention:

[0030] to combine Figure 1-Figure 4 ;The ore mined in the mining area is transported by car to the gyratory crushing station, and enters the crushing system for three-stage and one closed-circuit crushing. The raw ore particle size is 0~1200mm, and the product particle size is 0~50mm;

[0031] 01: The raw ore (product particle size 0~50) is transported by the belt to the high-pressure roller mill weighing steady flow bin.

[0032] 02: During the raw ore transportation process, the iron removal device removes the iron in the ore powder to protect the high pressure roller mill from damage. Extend the service life of the high pressure roller mill. Regarding the high-pressure roller mill, you can refer to the high-pressure roller mill for metal mine-200910116979.8 or the high-pressure roller mill for metal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com