Coupling method of MTO process and propane dehydrogenation process

A propane dehydrogenation and process technology, applied in the fields of hydrocarbons, hydrocarbons, chemical instruments and methods, can solve the problems of high equipment investment, large floor space, low recovery rate of low-carbon olefins, etc. The effect of land area, reducing investment cost and improving recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

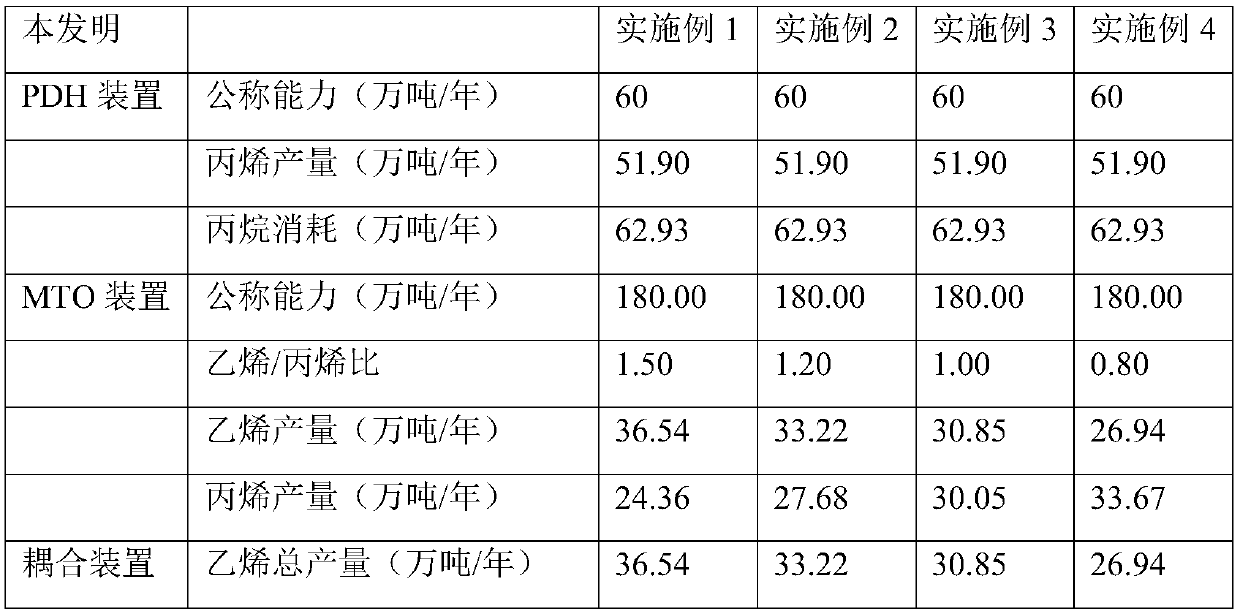

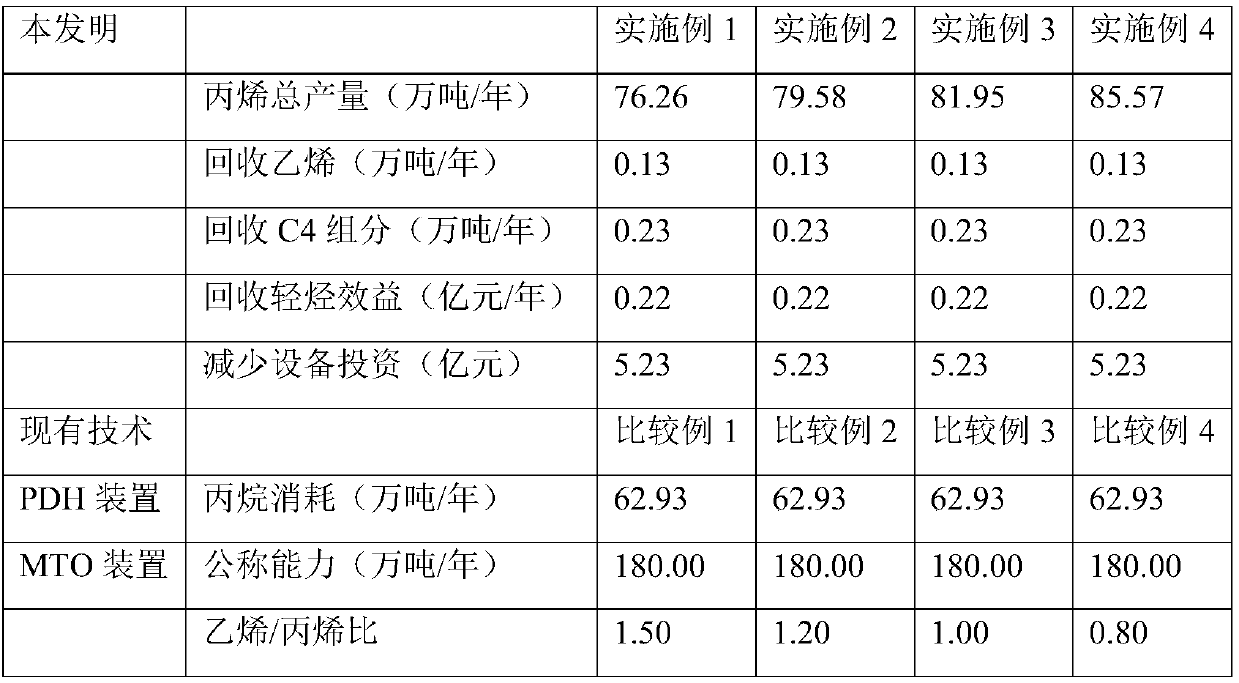

[0026] The nominal capacity of the MTO device in the present invention is 1.8 million tons / year, the reaction intensity: ethylene / propylene ratio=1.5, the output of ethylene is 365,400 tons / year, and the output of propylene is 243,600 tons / year. The PDH unit has a nominal capacity of 600,000 tons / year and a propylene output of 519,000 tons / year.

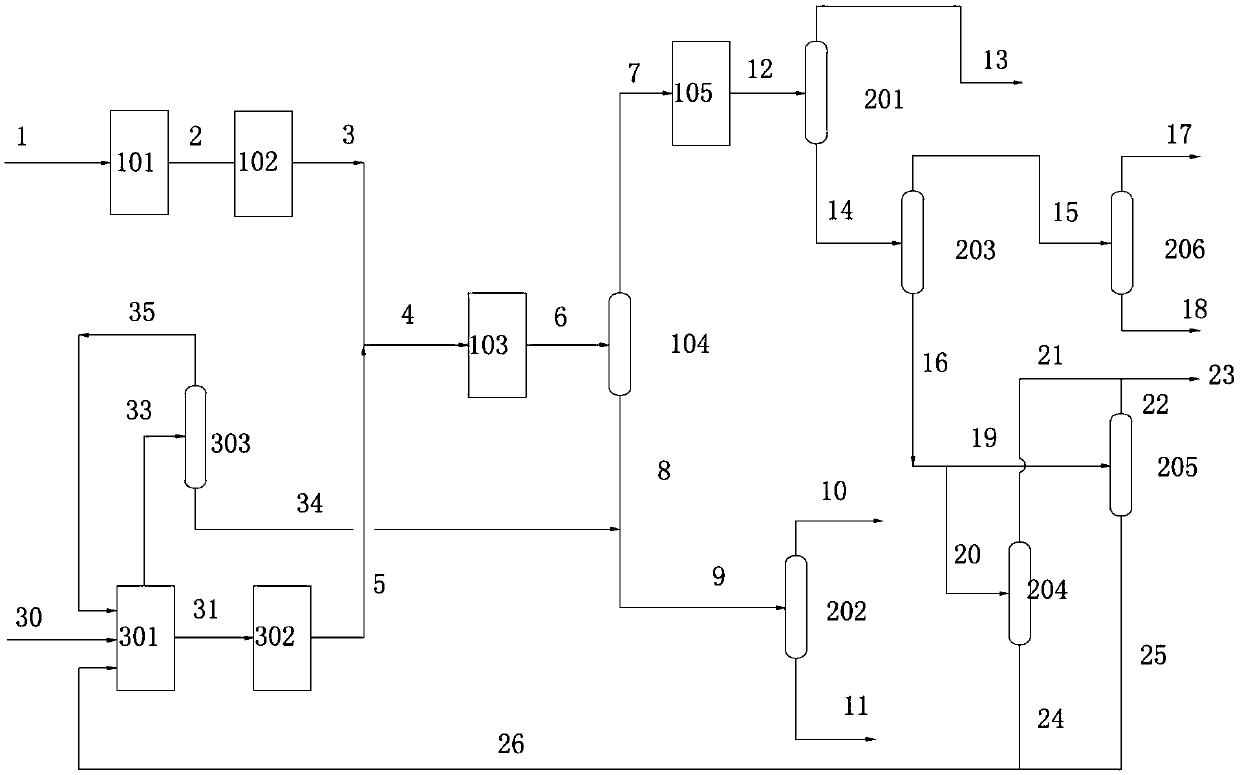

[0027] The technological process is as follows: the raw material methanol (1) is sent into the MTO reaction unit (101) for catalytic reaction, the reaction product gas (2) flows out from the MTO reaction unit (101) and enters the quenching unit (102), and the product gas (3 ) and the product gas (5) from the heating furnace of the PDH device and the reactor unit are merged into the material (4) and enter the compressed alkali washing unit (103), and enter the MTO depropanizer (104) after compression, and the MTO depropanizer (104) After the C4 and heavier components (8) of the tower bottom flow out, they are combined with the PDH deo...

Embodiment 2

[0034] The nominal capacity of the MTO device in the present invention is 1.8 million tons / year, the reaction intensity: ethylene / propylene ratio=1.2, the output of ethylene is 332,200 tons / year, and the output of propylene is 276,800 tons / year. The PDH unit has a nominal capacity of 600,000 tons / year and a propylene output of 519,000 tons / year. After adopting the integration method of the present invention, the equipment load of existing MTO device is promoted as follows:

[0035] serial number

[0036] Therefore, using the process coupling method of the present invention, compared with the existing MTO unit and PDH unit, the recovery of ethylene is 1,300 tons / year, the recovery of C4 components is 2,300 tons / year, and the benefit of recycling light hydrocarbons is 22 million yuan / year , reducing equipment investment by 523 million yuan, and reducing the area occupied by 1.8 hectares.

Embodiment 3

[0040] The nominal capacity of the MTO device in the present invention is 1.8 million tons / year, the reaction intensity: ethylene / propylene ratio=1.0, the output of ethylene is 308,500 tons / year, and the output of propylene is 300,500 tons / year. The PDH unit has a nominal capacity of 600,000 tons / year and a propylene output of 519,000 tons / year. After adopting the integration method of the present invention, the equipment load of existing MTO device is promoted as follows:

[0041] serial number

[0042] Therefore, using the process coupling method of the present invention, compared with the existing MTO unit and PDH unit, the recovery of ethylene is 1,300 tons / year, the recovery of C4 components is 2,300 tons / year, and the benefit of recycling light hydrocarbons is 22 million yuan / year , reducing equipment investment by 523 million yuan, and reducing the area occupied by 1.8 hectares.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com