Method of repairing local damaged coating on metal surface

A metal surface, local technology, applied to the device for coating liquid on the surface, pretreatment surface, coating, etc., can solve problems such as inability to overcome defects, ineffectiveness, etc., to reduce the texture of the paint surface and the color paint layer. The rough process, saving time and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

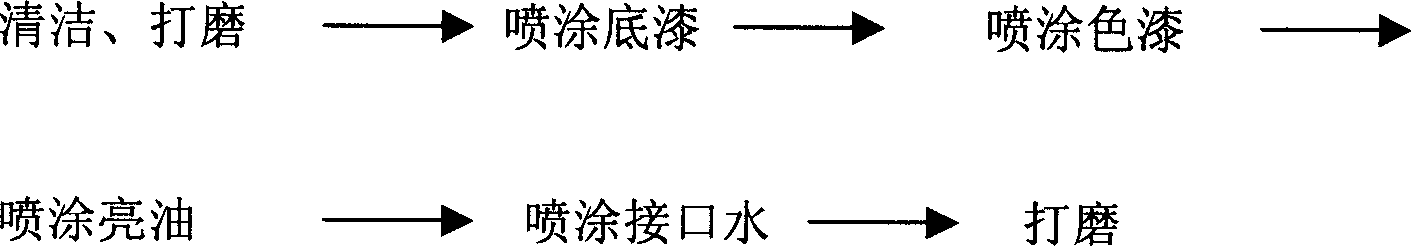

[0035] The damaged car was a black Mercedes-Benz sedan. There was a 3.5cm-diameter damage on the paint surface of the front cover, and the damage was uneven. The repair methods used are:

[0036] First of all, use 400# water sandpaper to thoroughly clean and polish the damaged part, polish the damaged and weakly adhered paint leather, and remove the oil stains, wax stains and dirt on the surface. Fill the uneven part with putty and further smooth the surface with 500# water sandpaper.

[0037] Spray the primer on the place where the putty is filled. The selected primer is American PPG Gaoba primer, and the thickness of the sprayed primer is 10% of the thickness of the original paint. After the primer is dry, sand the area within 4 times the area of the sprayed primer: first use 600# water sandpaper to polish the area within 2 times the area of the sprayed primer, and then use 1500# water sandpaper Sand the rest of the entire sanded area. Thoroughly polished and cleaned ...

Embodiment 2

[0044] With embodiment 1, the difference is that the damaged vehicle is a white car, and its front door has been scraped a scratch of about 5cm.

[0045] The difference in the process is that the damaged part is polished with 500# water sandpaper at the first grinding, and then the scratched part is filled with putty, and then smoothed with 600# water sandpaper after filling. The primer selected for spraying is the acrylic modified anti-rust primer of Guangdong Zhongshan Sencai Machinery Coating Company, and the thickness of the sprayed primer is 30% of the thickness of the original paint surface. After the primer is dry, sand the area within 5 times the area of the sprayed primer: first use 800# water sandpaper to polish the area within 3 times the area of the sprayed primer, and then use 1800# water sandpaper Sand the rest of the entire sanded area.

[0046] When spraying the paint, the selected paint is American PPG white paint. Spray in an area within 3 times the are...

Embodiment 3

[0051] With embodiment 1, the difference is that the damaged vehicle is a sapphire blue motorcycle, and its body has been rubbed off with a length of 4 centimeters and a paint surface of about 3 centimeters wide.

[0052] The difference in the process is that the damaged part is polished with 600# water sandpaper during the first grinding. Because the damaged area does not need to be filled, the primer is sprayed directly. The selected primer is the waterborne epoxy automotive primer from Wujin Xinhua Chemical Factory. The thickness of the spray primer is 50% of the thickness of the original paint surface. After the primer is dry, sand the area within 5 times the area of the sprayed primer area: first use 1000# water sandpaper to polish the area within 2 times the area of the sprayed primer area, and then use 2000# water sandpaper Sand the rest of the entire sanded area.

[0053] The color paint used when spraying the color paint is the automobile and motorcycle paint o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com