Tobacco particles, low-temperature smoke generating body, preparation method and heat-not-burn appliance

A technology of tobacco particles and smoke body, which is applied in the fields of tobacco, tobacco treatment, application, etc., can solve the problems of excessive moisture absorption of tobacco particles, achieve good smoke stability and uniformity, ensure stability, and ensure consistency sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

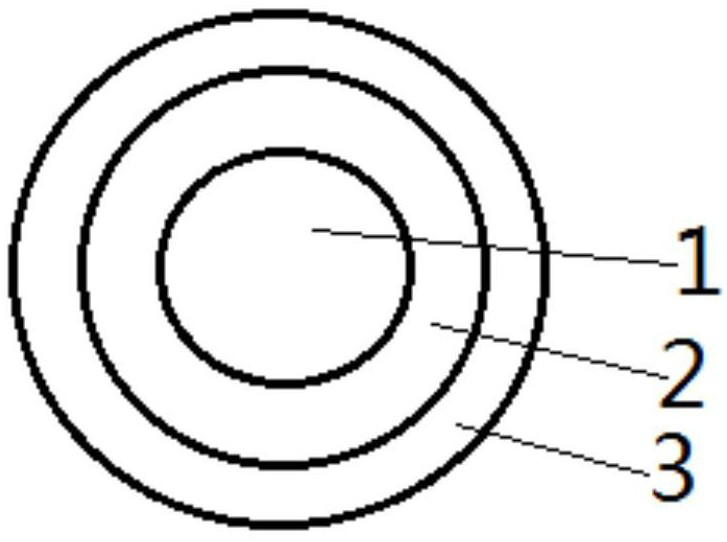

Image

Examples

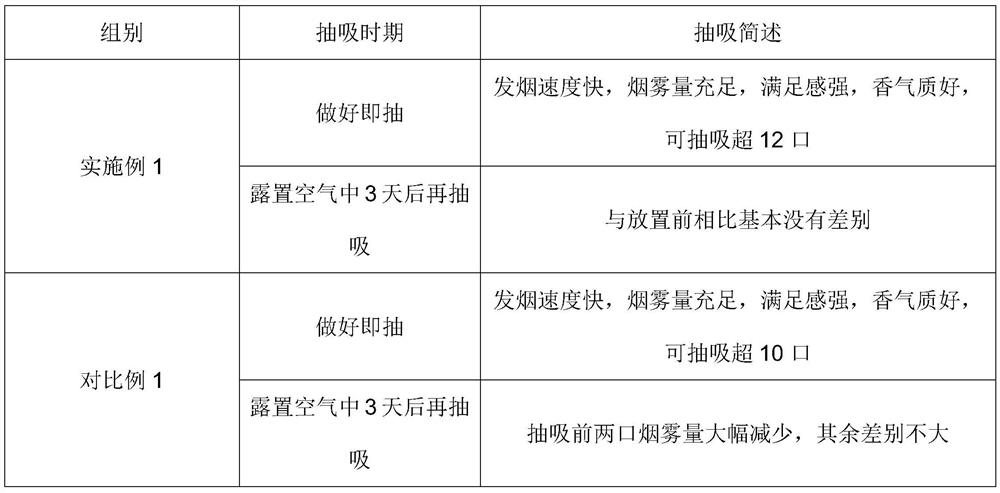

Embodiment 1

[0047] The preparation method of the low-temperature smoke body of this embodiment includes the following steps:

[0048] 1) In parts by mass, take 100 parts of 80-150 mesh tobacco powder; get 4 parts of tobacco extract, 15 parts of glycerin, 5 parts of glycerol, 1 part of polyethylene glycol, and 8 parts of 90wt% alcohol, and mix them Spray in the above-mentioned tobacco powder after uniformity, and mix evenly, adopt extruding spheronization granulation to obtain soft moist tobacco granule, room temperature air-drying; Carry out the first layer of coating on the above-mentioned softened tobacco particles after drying, and dry simultaneously to obtain the semi-finished tobacco particles; 3) carry out the second layer of coating on the above-mentioned semi-finished products with the hydroxypropyl cellulose aqueous solution according to the particle mass ratio of 10%, synchronously Dry to obtain the finished product of tobacco granules with low hygroscopicity, the moisture conte...

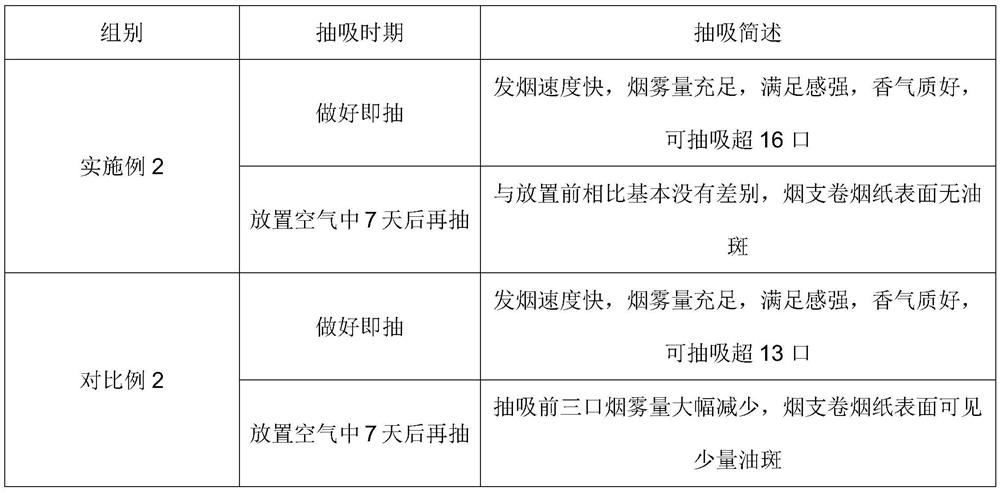

Embodiment 2

[0053] The preparation method of the low-temperature smoke body of this embodiment includes the following steps:

[0054] 1) In parts by mass, take 100 parts of 100-200 mesh tobacco powder; take 10 parts of tobacco extract, 10 parts of glycerin, 10 parts of glycerol, 5 parts of propylene glycol, and 10 parts of purified water, mix them evenly and spray them on the above-mentioned Tobacco powder, and mixed evenly, using the swing granulation method to obtain soft and moist tobacco particles, dried in a fluidized bed at 40°C, and sieved to get 25-35 mesh tobacco particles; 2) Beeswax and stearin with a mass ratio of 1:2 Acid adopts hot-melt coating method to carry out first layer coating to above-mentioned softening tobacco granule, coating layer accounts for 4% of tobacco granule quality, obtains tobacco granule semi-finished product; The above-mentioned semi-finished product is coated with the second layer, and dried synchronously to obtain the finished product of low-hygrosco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com