Preparation method and application of cut stems with relatively high concentration

A kind of cut stem, a larger technology, applied in the application and processing of tobacco, tobacco, etc., can solve the problem of less research on cut stems and other substances, reduce unpleasant smell and irritation, increase sensory quality, increase smoke volume and aroma components Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

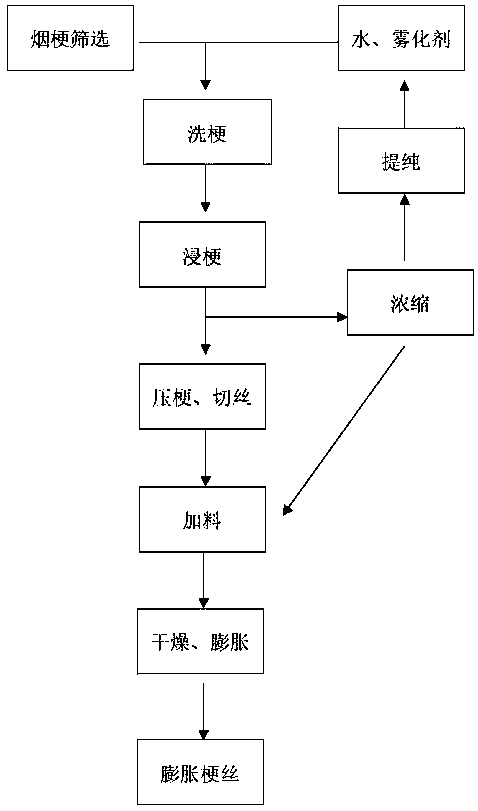

[0028] The embodiment of the present invention provides a method for preparing cut stems with relatively high concentration, the flow chart is as follows figure 1 shown, including the following steps:

[0029] (1) The raw tobacco stems are fed and screened, and the size of the tobacco stems is greater than 4 15mm;

[0030] (2) Use the mixed aqueous solution containing the atomizing agent to wash and soak the raw tobacco stems after screening, and concentrate the mixed aqueous solution after washing and soaking the stems, and separate the water and the concentrated tobacco containing the atomizing agent. liquid;

[0031] (3) Squeezing and shredding the raw tobacco stems that have undergone stem washing and soaking;

[0032] (4) Adding concentrate to the raw tobacco stems that have been processed by pressing and shredding;

[0033] (5) Drying and expanding the processed raw tobacco stems.

[0034] Preferably, the method for preparing cut stems with relatively high concentr...

Embodiment 1

[0043] Embodiment 1 of the present invention provides a method for preparing cut stems with a relatively high concentration, comprising the following steps:

[0044] (1) Quantitative feeding of raw tobacco stems, unpacking, and screening of tobacco stems with a size of 10 15mm size;

[0045] (2) Washing and soaking of stems: Use a mixed solution of 45°C water and atomizing agent (propylene glycol and glycerin, volume ratio 2:1) for washing and soaking of stems; the ratio of water to atomizing agent is 2:1, mix The ratio of the solution to the tobacco stems is 1.1:1 to ensure that the tobacco stems are fully infiltrated by the mixed solution, and the infiltration time is 60 minutes. After washing and soaking the stems, the mixed solution is distilled and concentrated, the concentrated solution is ready for use, and the recovered water and atomizing agent can be recycled.

[0046] (3) Stem pressing and shredding: the gap between pressing rollers is 0.8 mm, and the thickness o...

Embodiment 2

[0054] Embodiment 2 of the present invention provides a method for preparing cut stems with relatively high concentration, comprising the following steps:

[0055] (1) Quantitative feeding and unpacking of the raw tobacco stems, the size of the tobacco stems is 10×15mm;

[0056] (2) Washing and soaking of stems: use a mixed solution of 60°C water and atomizing agent (glycerin) for washing and soaking of stems; the ratio of water to atomizing agent is 3:1, and the ratio of mixed solution to tobacco stems is 1.1:1 , to ensure that the tobacco stems are fully infiltrated by the mixed solution, and the infiltration time is 45 minutes. After the mixed solution is distilled and concentrated, the concentrated solution is ready for use, and the recovered water and atomizing agent can be recycled.

[0057] (3) Pressing stems and shredding: the gap between pressing rollers is 1.0 mm, and the thickness of stems is 0.10 mm.

[0058] (4) Feeding treatment: The mass percentage of feed is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com