Heating cigarette with lateral air inlet function

A cigarette and functional technology, applied in the field of heated cigarettes, can solve the problems of unstable volatilization of aroma substances, reduction of smoke volume and aroma substances, and easy oxidation reaction of tobacco substances.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

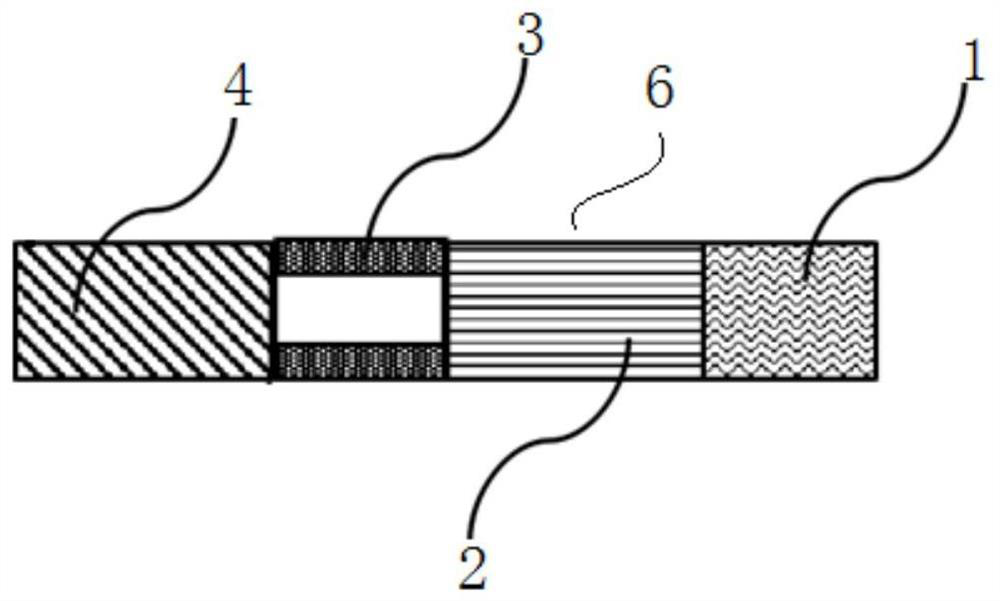

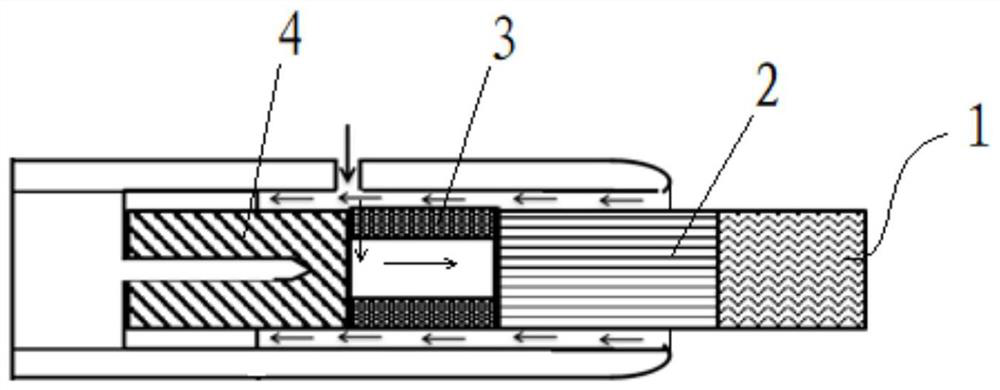

[0027] This embodiment proposes a heated cigarette with a side air intake function, wherein the heated cigarette is composed of a tobacco substance segment 4 and a filter rod functional segment 1; that is, in this embodiment, the heated cigarette is composed of two functional segments , one is the tobacco substance segment 4, and the other is the filter rod functional segment 1. The main improvement of this embodiment is that the connection between the tobacco substance section 4 and the filter rod functional section 1 is provided with an air inlet; that is to say, the air inlet in the present invention is arranged in the tobacco substance section 4 and the connection of the filter rod functional section 1, during the suction process, most of the external air enters the cigarette from the side air intake holes of the heated cigarette, so that the amount of air passing through the tobacco material section 4 in the axial direction is reduced. Specifically, the tobacco material s...

Embodiment 2

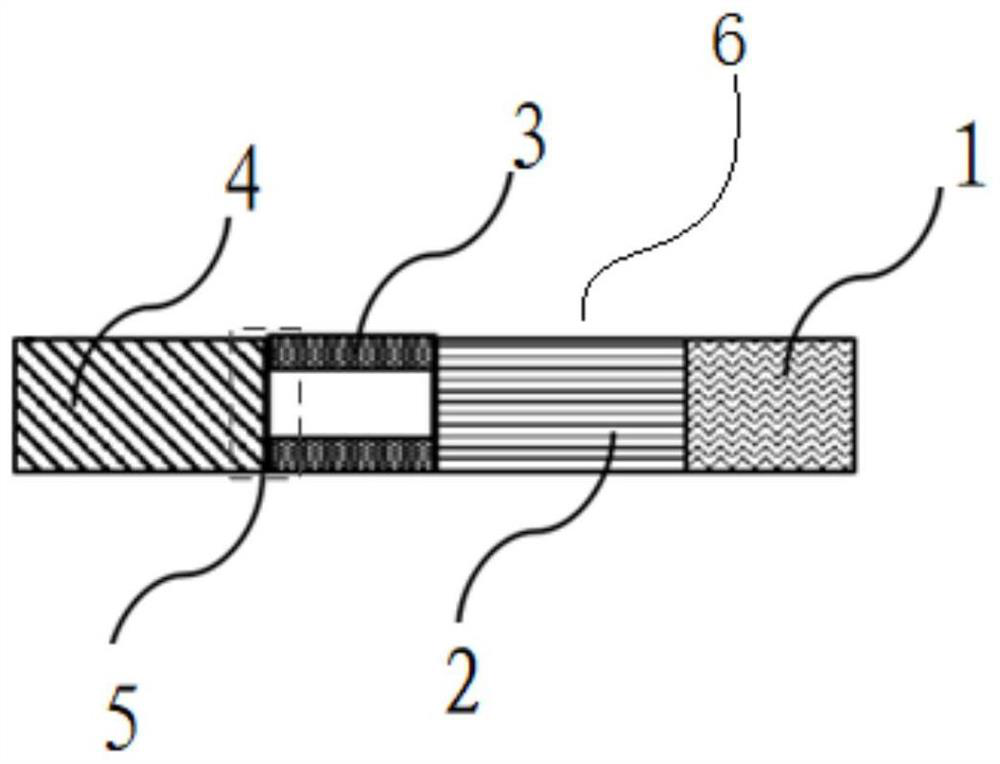

[0030] The difference between this embodiment and Embodiment 1 is that in Embodiment 1, the functional section 1 of the filter rod is a single structure, while in this embodiment, the functional section 1 of the filter rod is a multi-component composite structure, especially, the functional section 1 in this embodiment The functional segment 1 of the filter rod is a ternary composite structure. That is, the functional section 1 of the filter rod in this embodiment is provided with a filter section 6 , a cooling section 2 and a hollow section 3 in sequence along the direction close to the tobacco substance section 4 .

[0031] Specifically, the hollow section 3 is a hollow structure for the confluence of smoke and air; the cooling section 2 is used to reduce the temperature of the smoke; the filter section 6 is used to filter the smoke and heat the cigarette. In the four-section structure, every two The connection mode of the segments is the same as that of the prior art. It sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com