Application of supported L-proline catalyst in continuous flow chemistry

A catalyst, proline technology, applied in catalytic reactions, physical/chemical process catalysts, organic chemistry, etc., can solve the problems affecting the normal progress of continuous flow synthesis, clogging, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A kind of continuous flow catalytic reaction device structure of the present embodiment is as follows figure 1 shown. A high-precision micro-syringe pump is used to pump the reaction solution through the columnar reactor at a certain flow rate. The reactor is filled with a certain mass of L-Proline / MWCNTs catalyst (Cat) and additional carrier neutral alumina, the particle size is 100-200 mesh, the mass of neutral alumina is 20 grams, and the fluid containing the product is continuously received at the liquid outlet .

[0037] 15g of L-proline was dissolved in ultrapure water (30mL) and sonicated for 30min to prepare a solution, then 1g of multi-walled carbon nanotubes (MWCNTs) was added to the above solution and stirred at room temperature for 12h. Then, the obtained solid catalyst was washed with water (3 times) by means of centrifugation (5000rpm), and the collected black precipitate was vacuum-dried overnight at 80° C. to obtain the L-proline supported by multi-wal...

Embodiment 2

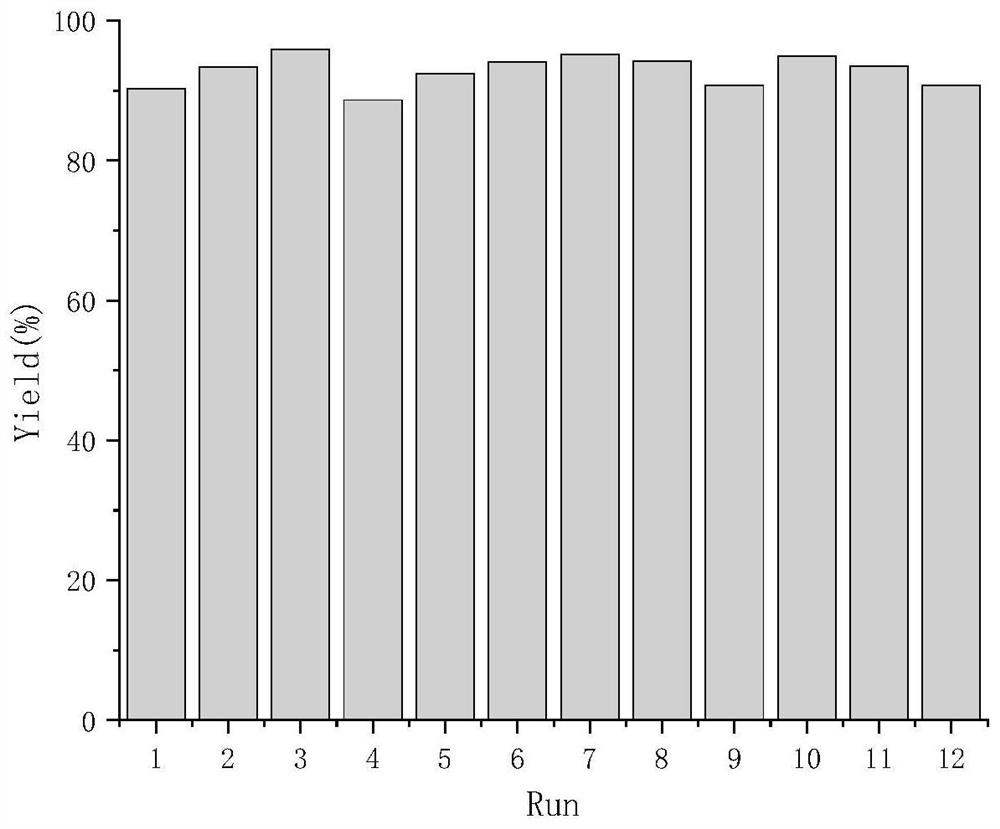

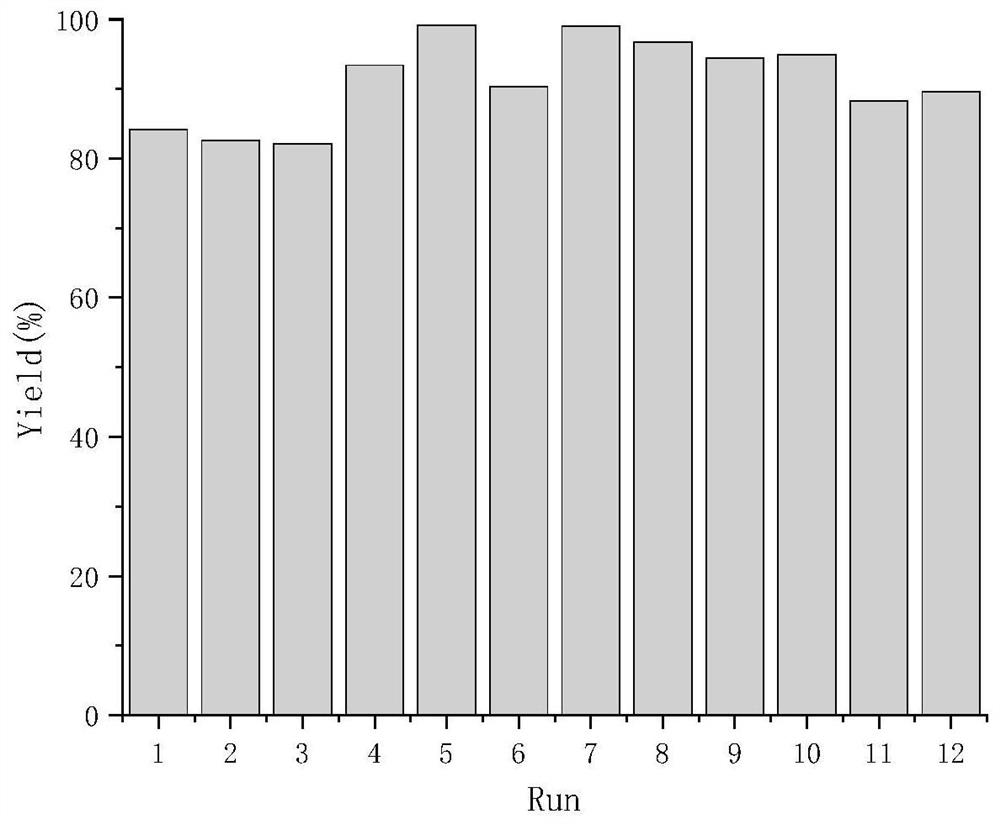

[0044] In Example 1, keeping the volume and concentration of the reaction solution constant, the flow rate of the reaction solution was doubled to 5mL / h, and the collected product yield was 90.3%.

Embodiment 3

[0046] In embodiment 2, keep adding reaction solution volume and flow velocity constant, increase the concentration of p-nitrobenzaldehyde in the reaction solution to be 0.08mol / L, 0.2mol / L respectively, collect the product yield that obtains at liquid flow outlet They are 78.6% and 56.7% respectively.

[0047] In above-mentioned example 1-3, through comprehensive comparative analysis, can obtain that adding catalytic component is 3.0gCat / 20gAl 2 o 3 , the concentration of the reaction solution is 0.04mol / L, the volume of the reaction solution added each time is 5mL, and the flow rate of the reaction solution pumped into the syringe pump is 5mL / h, which can continuously obtain the product of more than 90% yield.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com