Electronic cigarette power control method, device and system

A power control and electronic cigarette technology, applied in the field of electronic cigarettes, can solve the problems of inability to simulate the taste of smoking a large amount of smoke from tobacco cigarettes, insufficient user experience, and no change in the amount of smoke.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

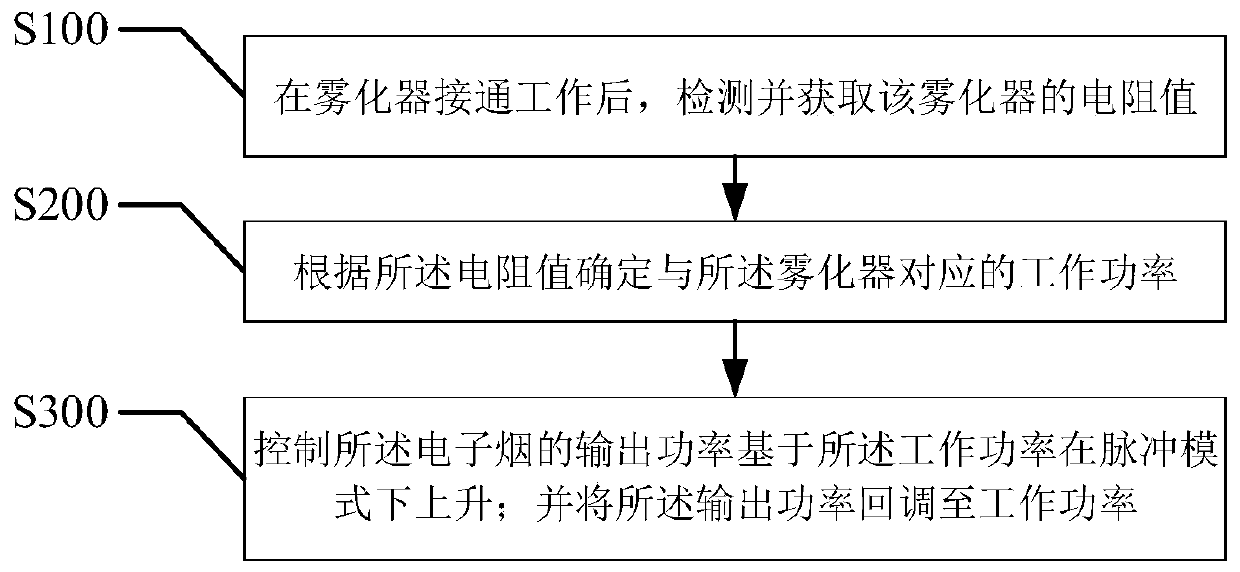

[0060] refer to figure 2 , the first embodiment of the present invention provides an electronic cigarette power control method, including:

[0061] Step S100, after the atomizer is turned on and working, detect and obtain the resistance value of the atomizer;

[0062] Step S200, determining the working power corresponding to the atomizer according to the resistance value;

[0063] Step S300, controlling the output power of the electronic cigarette to rise in pulse mode based on the working power; and returning the output power to the working power.

[0064] It should be noted that although there are many types and styles of electronic atomizers, they generally consist of three parts: batteries, atomizers, pods, and other accessories (including chargers, wires, atomizing rings, etc.) .

[0065] 1. Battery: The internal structure of the battery uses the same basic components: a light PCBA board, a rechargeable battery, and an electronic circuit.

[0066] 2. Atomizer: The st...

Embodiment 2

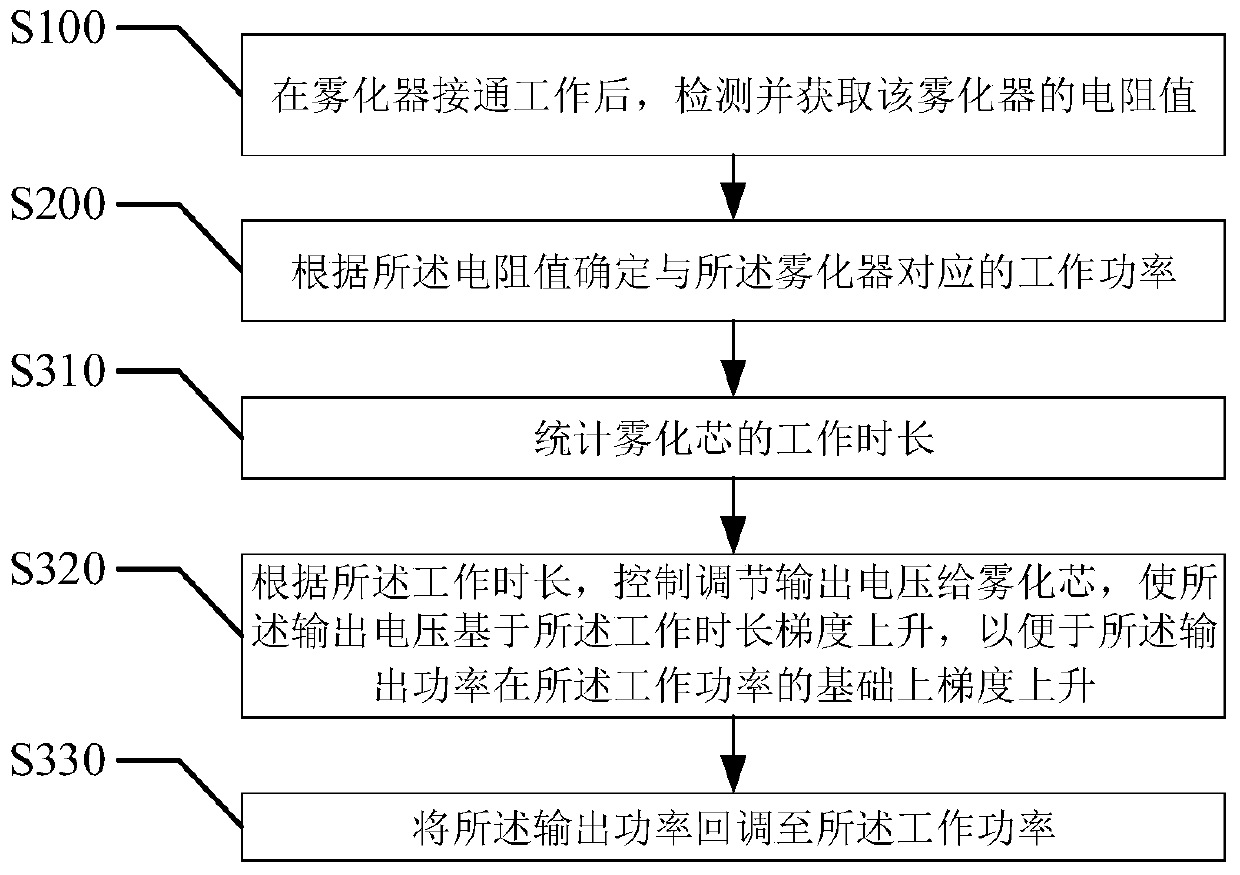

[0073] refer to image 3 , based on the above-mentioned embodiment, the second embodiment of the present invention provides a power control method of an electronic cigarette, the step S300, "control the output power of the electronic cigarette to rise in the pulse mode based on the working power; and the "Output power back to work power" includes:

[0074] Step S310, counting the working hours of the atomizing core;

[0075] As mentioned above, the working time of the atomizing core is the timing of the atomizing core starting from the user’s inhalation, that is, the duration from the start of inhalation is the working time. The time when they stop working is not counted in the working hours.

[0076] Step S320, according to the working time, control and adjust the output voltage to the atomizing core, so that the output voltage increases gradually based on the working time, so that the output power increases gradually on the basis of the working power;

[0077] After obtai...

Embodiment 3

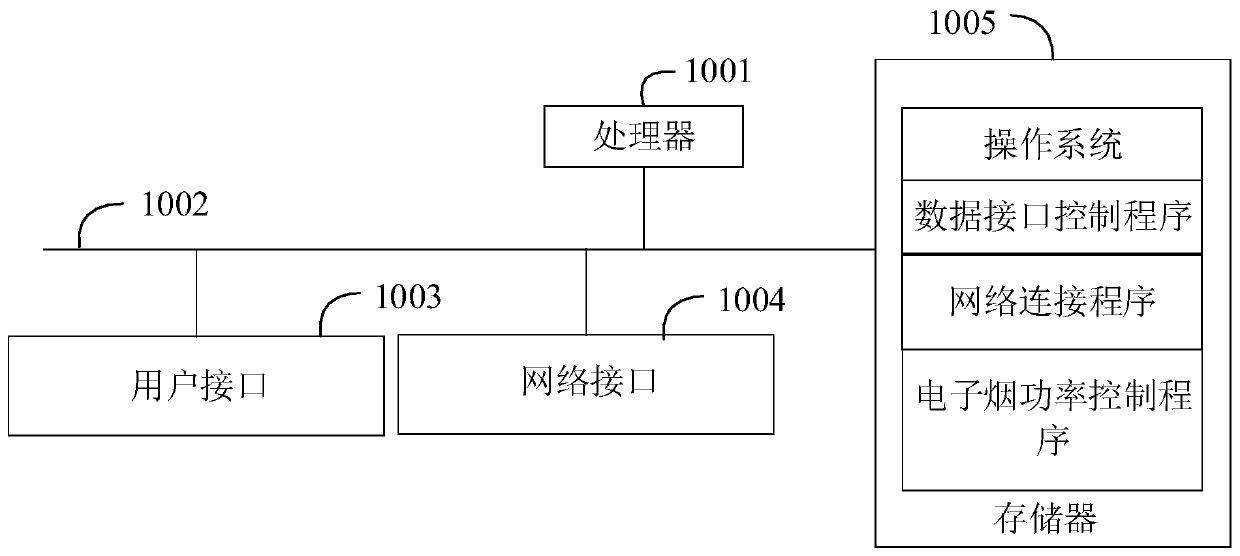

[0100] Based on the above embodiments, this embodiment provides an electronic cigarette power control device, including:

[0101] The resistance detection module is used to detect and obtain the resistance value of the atomizer after the atomizer is switched on;

[0102] A resistance matching module, configured to determine the working power corresponding to the atomizer according to the resistance value;

[0103]The power control module is used to control the output power of the electronic cigarette to rise in the pulse mode based on the working power; and return the output power to the working power.

[0104] Such as Figure 4 As shown, the power circuit is used to process the output power of the battery assembly and convert it into different voltages to supply other components. The power circuit also includes a button module, which is used to switch the power supply of the electronic cigarette, such as Figure 4 The middle is the circuit diagram of the button module in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com