Porous ceramic for electronic cigarette and preparation method thereof

A porous ceramic and electronic cigarette technology, applied in the field of electronic cigarettes, can solve the problems of inability to satisfy consumers' smoking frequency and taste, poor atomization effect of e-liquid, uneven pore size distribution, etc. Improve the effect of smoke volume and uniform pore size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

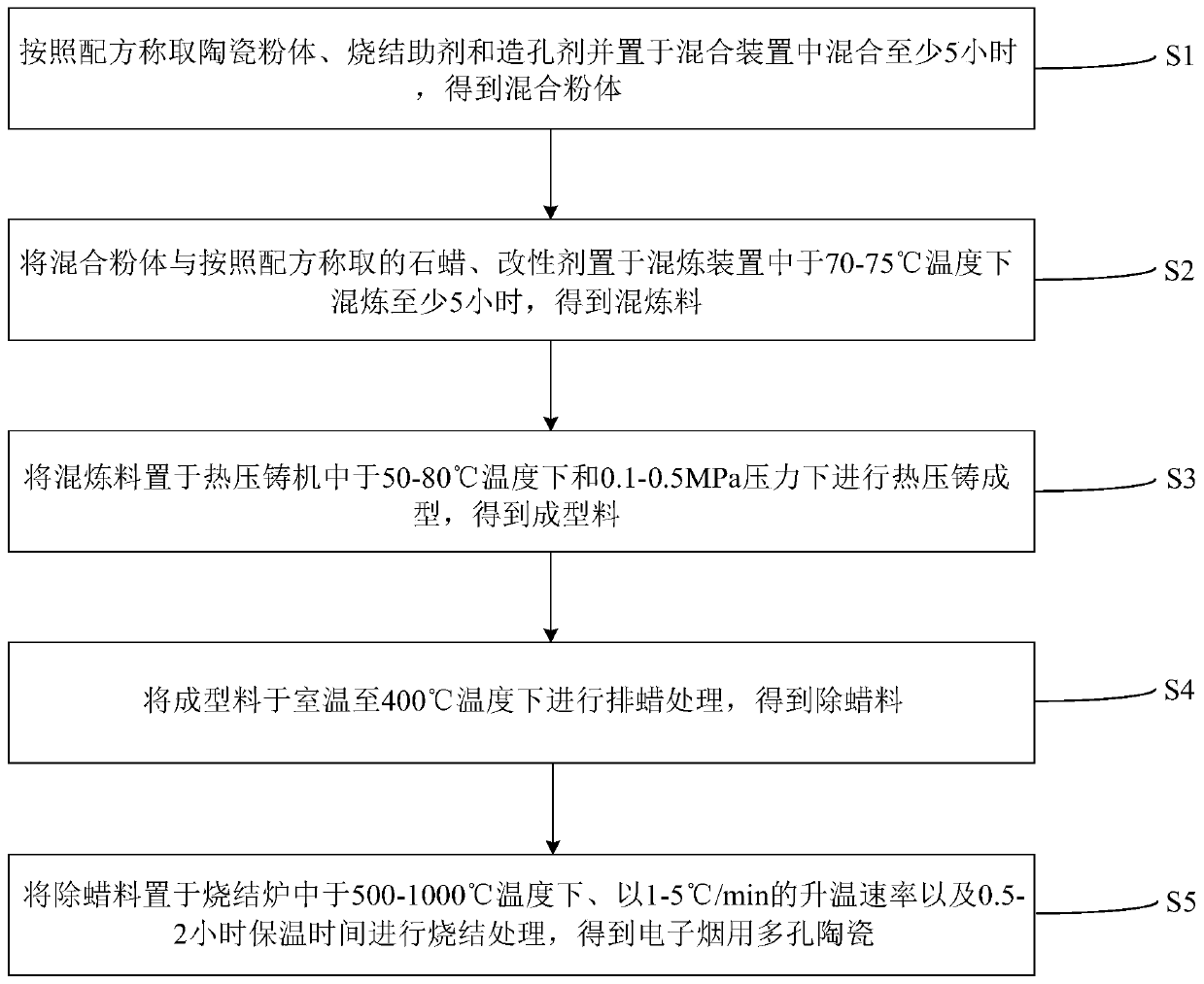

[0040] The embodiment of the present invention also discloses a preparation method of porous ceramics for electronic cigarettes, please refer to figure 1 , figure 1 It is a schematic flowchart of a method for preparing porous ceramics for electronic cigarettes according to an embodiment of the present invention, and the method includes:

[0041] Step S1: Weigh the ceramic powder, sintering aid, and pore-forming agent according to the formula, place them in a mixing device and mix for at least 5 hours to obtain a mixed powder.

[0042] In step S1, the mixing device includes one of a roller mill, a V-type mixer and a planetary ball mill. Preferably, in this embodiment, the mixing device is a V-type mixer. By mixing the ceramic powder with the sintering aid and pore-forming agent, it is beneficial to increase the contact area between the ceramic powder, the sintering aid and the pore-forming agent, thereby improving the subsequent mixing efficiency and mixing effect.

[0043] S...

Embodiment 1

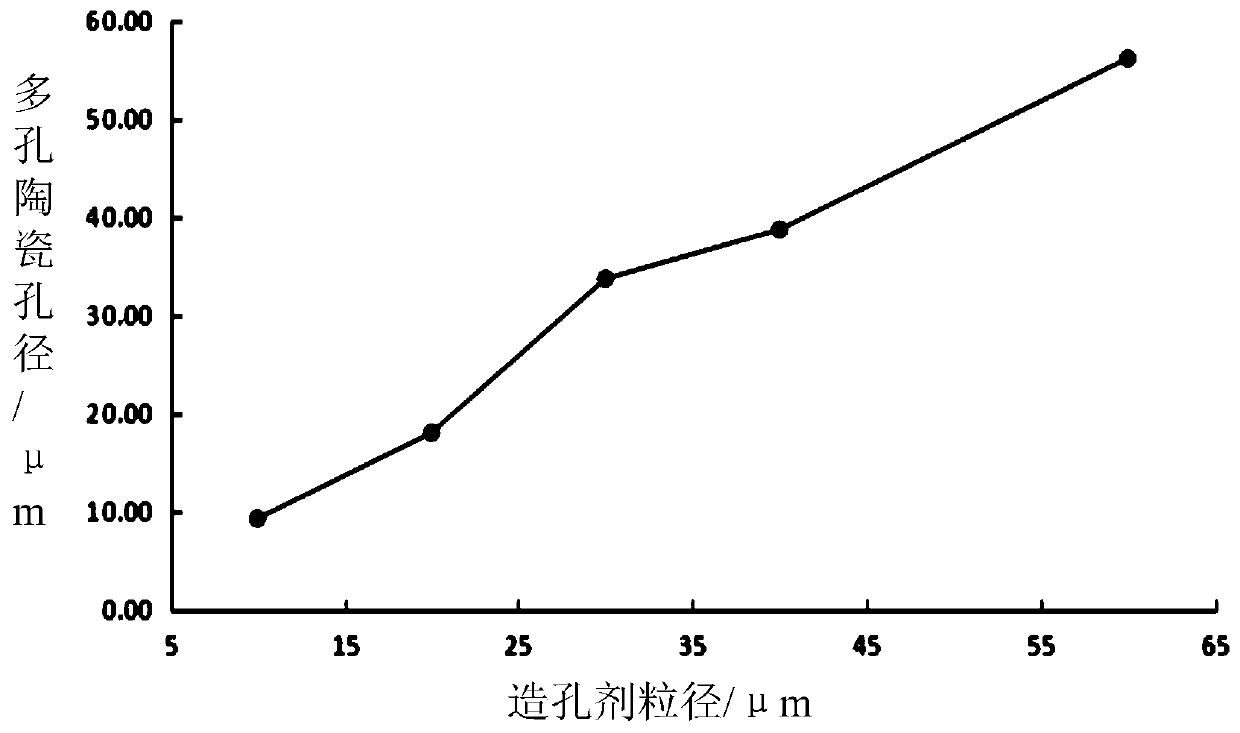

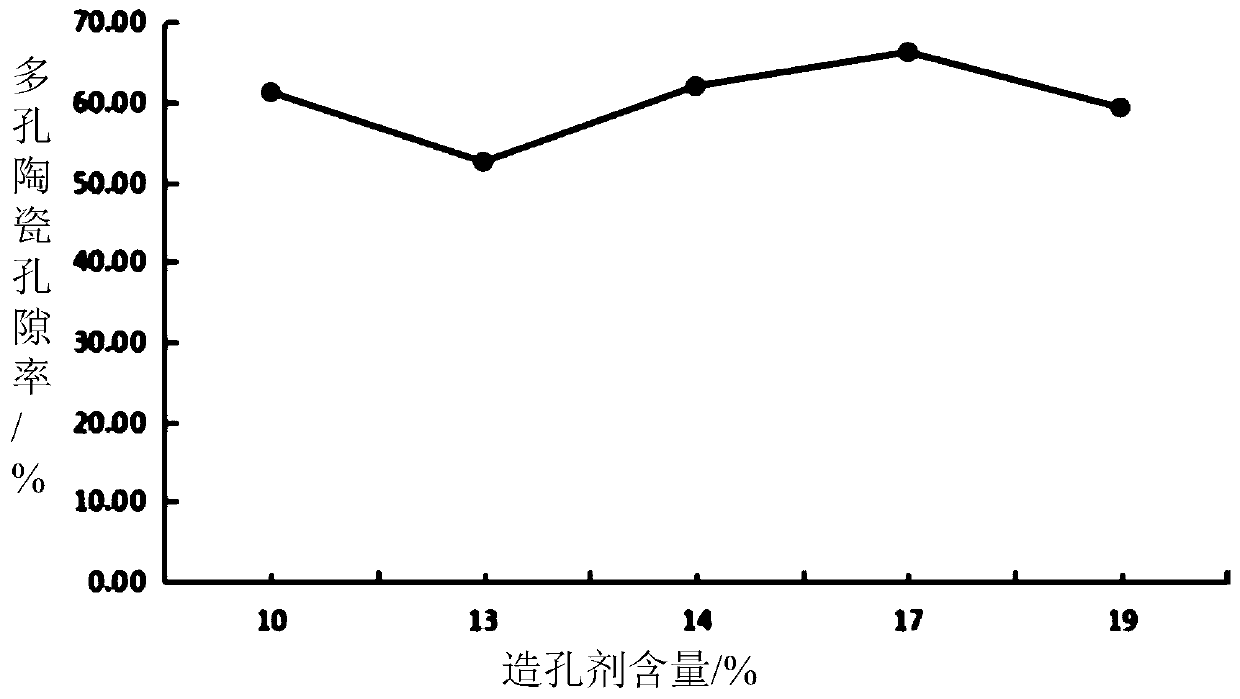

[0053] Weigh 30% diatomite, 5% glass sand, 10% polystyrene microspheres, 22% glass powder, 28% paraffin and 5% stearic acid, glass powder The softening temperature of the polystyrene microsphere is 480-560 °C, the particle size of the polystyrene microsphere is 10 μm, and the melting point of the paraffin is 58 °C.

[0054] S1: Put the weighed diatomite, glass sand, polystyrene microspheres and glass powder in a V-type mixer and mix for 5 hours to obtain a mixed powder;

[0055] S2: Put the mixed powder, weighed paraffin wax and stearic acid in a wax blender and knead for 5 hours at a temperature of 70°C to obtain a kneaded material;

[0056] S3: placing the mixed material in a hot die casting machine for hot die casting at a temperature of 60° C. and a pressure of 0.2 MPa to obtain a molding material;

[0057] S4: Perform wax removal treatment on the molding material at a temperature from room temperature to 400°C, the temperature rise rate from room temperature to 200°C is ...

Embodiment 2

[0060] Weigh respectively 32% diatomite, 8% quartz sand, 17% polystyrene microspheres, 20% glass powder, 18% paraffin and 5% oleic acid according to mass percentage, the glass powder The softening temperature is 850-950°C, the particle size of polystyrene microspheres is 20 μm, and the melting point of paraffin is 58°C.

[0061] S1: Put the weighed diatomite, quartz sand, polystyrene microspheres and glass powder in a V-type mixer and mix for 5 hours to obtain a mixed powder;

[0062] S2: Mixing the mixed powder with the weighed paraffin wax and oleic acid in a wax mixer at a temperature of 75°C for 5 hours to obtain a mixed material;

[0063] S3: placing the mixed material in a hot die casting machine for hot die casting at a temperature of 60° C. and a pressure of 0.2 MPa to obtain a molding material;

[0064] S4: Perform wax removal treatment on the molding material at a temperature from room temperature to 400°C, the temperature rise rate from room temperature to 200°C is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com