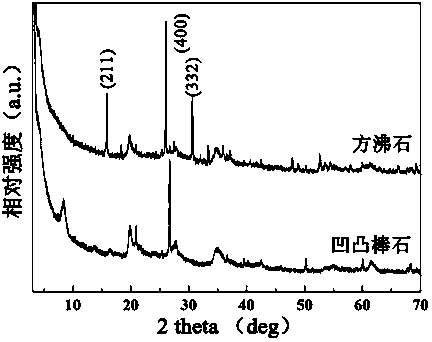

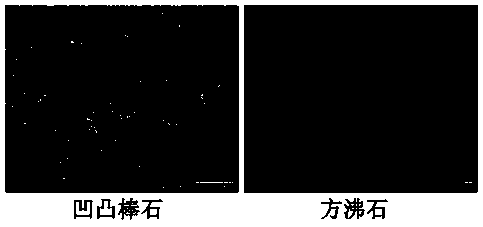

Method for preparing spherical analcime mesoporous material from low-quality attapulgite clay tailings

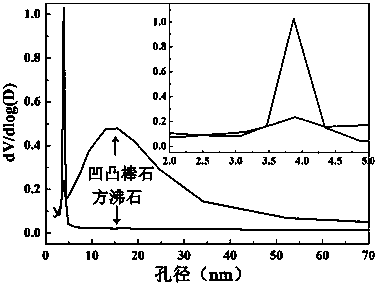

A technology of attapulgite clay and mesoporous materials, applied in the direction of crystalline aluminosilicate zeolite, etc., can solve the problem of incomplete conversion of attapulgite, and achieve the effects of stable product quality, uniform pore size distribution, and stable pore size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1: 100 g attapulgite clay (Al 2 o 3 , 10.5%; MgO, 2.5%; SiO 2 , 80%) were dispersed in 600mL aqueous solution containing 1g sodium sulfide, stirred and dissolved, ultrasonically treated for 65min, aged for 12h, transferred to a 5 L sealed hydrothermal reactor, and reacted for 100 h, the product is centrifuged, dried, and pulverized to obtain a spherical analcime mesoporous material.

Embodiment 2

[0026] Embodiment 2: 50 g attapulgite clay (Al 2 o 3 , 16%; MgO, 9%; SiO 2 , 70%) were dispersed in 3000 mL of aqueous solution containing 7.5 g of sodium carbonate and 2.5 g of potassium sulfide, stirred and dissolved, ultrasonically treated for 65 min, aged for 1 h, transferred to a 5 L sealed hydrothermal reactor, and heated at a pressure of 1.5 MPa , and reacted for 100 h at a temperature of 100 °C, the product was centrifuged, dried, and pulverized to obtain a spherical analcime mesoporous material.

Embodiment 3

[0027] Embodiment 3: 100 g attapulgite clay (Al 2 o 3 , 26%; MgO, 9%; SiO 2 , 55%) was dispersed in 3000 mL of aqueous solution containing 8 g sodium sulfite and 7 g sodium metaaluminate, stirred and dissolved, ultrasonically treated for 65 min, aged for 6 h, transferred to a 5 L sealed hydrothermal reactor, and heated at a pressure of 3 MPa , and react at a temperature of 180 °C for 20 h, and the product is centrifuged, dried, and pulverized to obtain a spherical analcime mesoporous material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com