Process for mfg. water resisting type large pore spherical silica gel

A technology of spherical silica gel and a manufacturing method, applied in the field of silica gel manufacturing, can solve the problems of cracking, uneven pore size distribution, unstable skeleton structure of macroporous silica gel, etc., achieve stable pore size distribution, shorten production cycle, and improve non-explosion in contact with water. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

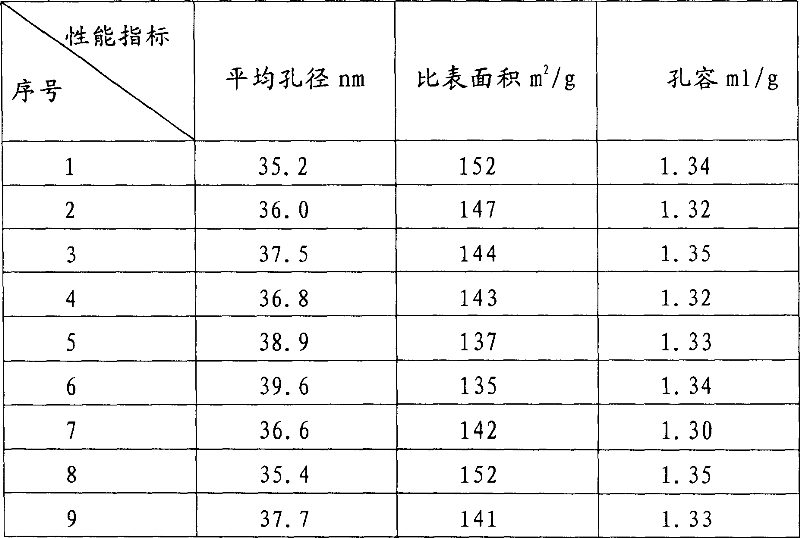

Examples

Embodiment 1

[0014] The manufacturing method process of the macroporous spherical silica gel of the present invention is as follows:

[0015] 1. Sodium silicate reacts with dilute sulfuric acid to prepare gel balls;

[0016] 2. Aging treatment process: 2 hours at 25°C;

[0017] 3. Steaming treatment process: steam pressure: 0.1MPa, steaming time 8 hours;

[0018] 4. Drying treatment process: the drying temperature is 120℃, and the time is 10 hours;

[0019] 5. The burning treatment process is: burning temperature is 500℃, burning time is 100min;

[0020] 6. Acid bubble treatment process: use 1-4% sulfuric acid for acid bubble treatment, and the acid bubble time is 2 hours;

[0021] 7. Washing treatment process: wash with water at 55°C until the pH value is 5-7.5;

[0022] 8. Drying treatment process: the drying temperature is 120°C and the time is 10 hours.

Embodiment 2

[0024] The manufacturing method process of the macroporous spherical silica gel of the present invention is as follows:

[0025] 1. Sodium silicate reacts with dilute sulfuric acid to prepare gel balls;

[0026] 2. Aging treatment process: 30℃ for 8 hours;

[0027] 3. Steam treatment process: steam pressure: 0.3MPa, steaming time 6 hours;

[0028] 4. Drying treatment process: the drying temperature is 200℃, and the time is 40 hours;

[0029] 5. The burning treatment process is: burning temperature is 600℃, burning time is 80min;

[0030] 6. Acid bubble treatment process: use 1-4% sulfuric acid for acid bubble treatment, and the acid bubble time is 8 hours;

[0031] 7. Washing treatment process: wash with water at 40-45°C until the pH value is 5-7.5;

[0032] 8. Drying treatment process: the drying temperature is 200°C and the time is 50 hours.

Embodiment 3

[0034] The manufacturing method process of the macroporous spherical silica gel of the present invention is as follows:

[0035] 1. Sodium silicate reacts with dilute sulfuric acid to prepare gel balls;

[0036] 2. Aging treatment process: 27℃ for 5 hours;

[0037] 3. Steaming treatment process: steam pressure: 0.4MPa, steaming time 8 hours;

[0038] 4. Drying treatment process: the drying temperature is 150℃, and the time is 30 hours;

[0039] 5. The burning treatment process is: burning temperature is 700℃, burning time is 80min;

[0040] 6. Acid bubble treatment process: use 1-4% sulfuric acid for acid bubble treatment, and the acid bubble time is 5 hours;

[0041] 7. Washing treatment process: wash with 45-50 ℃ water until the pH value is 5-7.5;

[0042] 8. Drying treatment process: the drying temperature is 150°C and the time is 30 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com