Plant essential oil mist atomizer and production method thereof

A plant essential oil and production method technology, applied in the field of plant essential oil mist, can solve the problems of reduced battery life, low oil conduction efficiency, and small smoke volume of plant essential oil mist, so as to improve service life, heat generation efficiency, and smoke volume Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings.

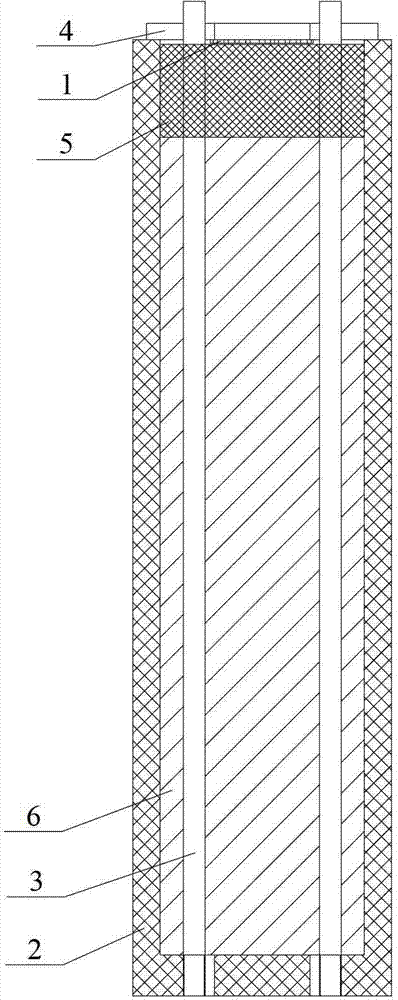

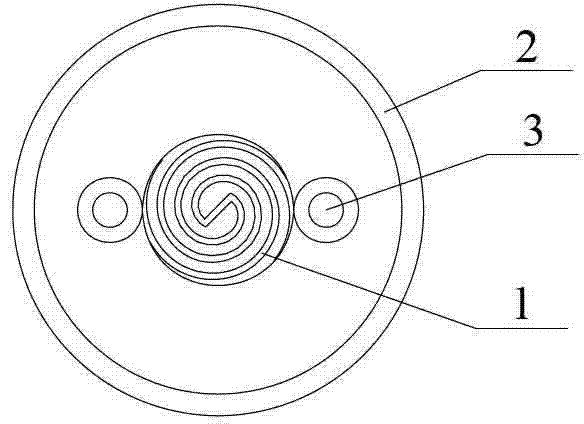

[0020] Such as figure 1 , figure 2 As shown, the nebulizer for plant essential oil mist provided by the present invention includes a heating wire 1 and an oil storage tube 2 . The oil storage pipe 2 is cylindrical, and the opening of the oil storage pipe 2 is covered with a heat-resistant glass fiber board 4, the glass fiber board 4 is in the shape of a disc, the heating wire 1 is bent into a plane curve, and the heating wire 1 is fixed on the glass fiber board 4 In this embodiment, the heating wire 1 is bent into a spiral shape, and the heating wire 1 and the glass fiber board 4 are pressed into a whole by a machine and assembled by automatic welding equipment.

[0021] The planar heating wire 1 has a high resistance value, and the atomization area has reached the limit of the heating wire with the same resistance value, so the heating efficiency is high, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com