Constant temperature control circuit and method for heat-not-burn cigarettes

A constant temperature control circuit, heating and non-combustion technology, applied in the field of electronic cigarettes, to achieve the effect of shortening the warm-up time, improving precision and accuracy, and ensuring consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

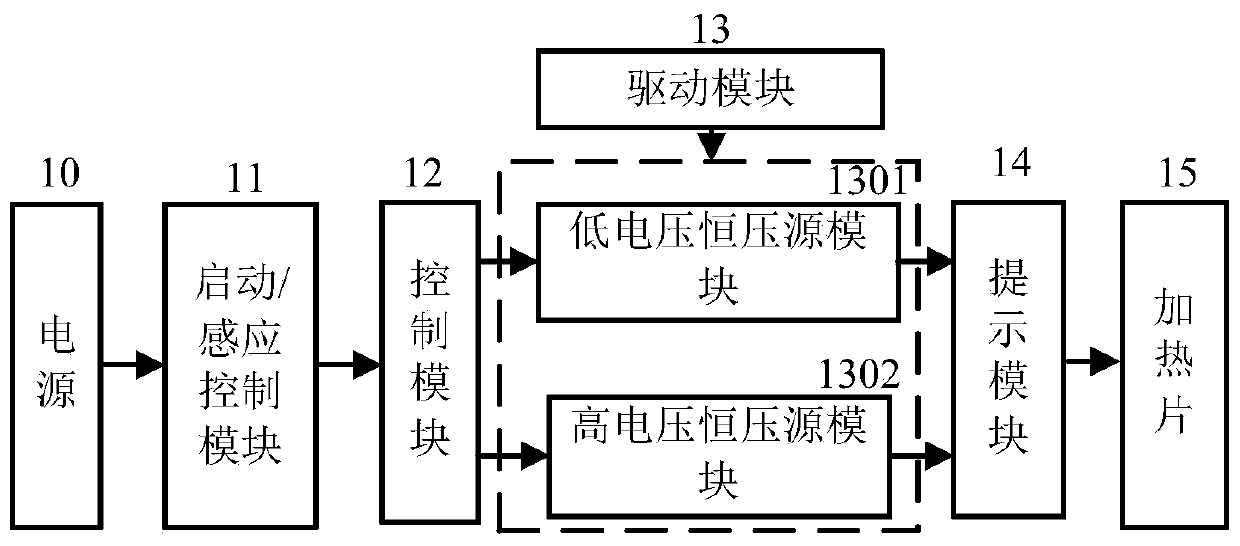

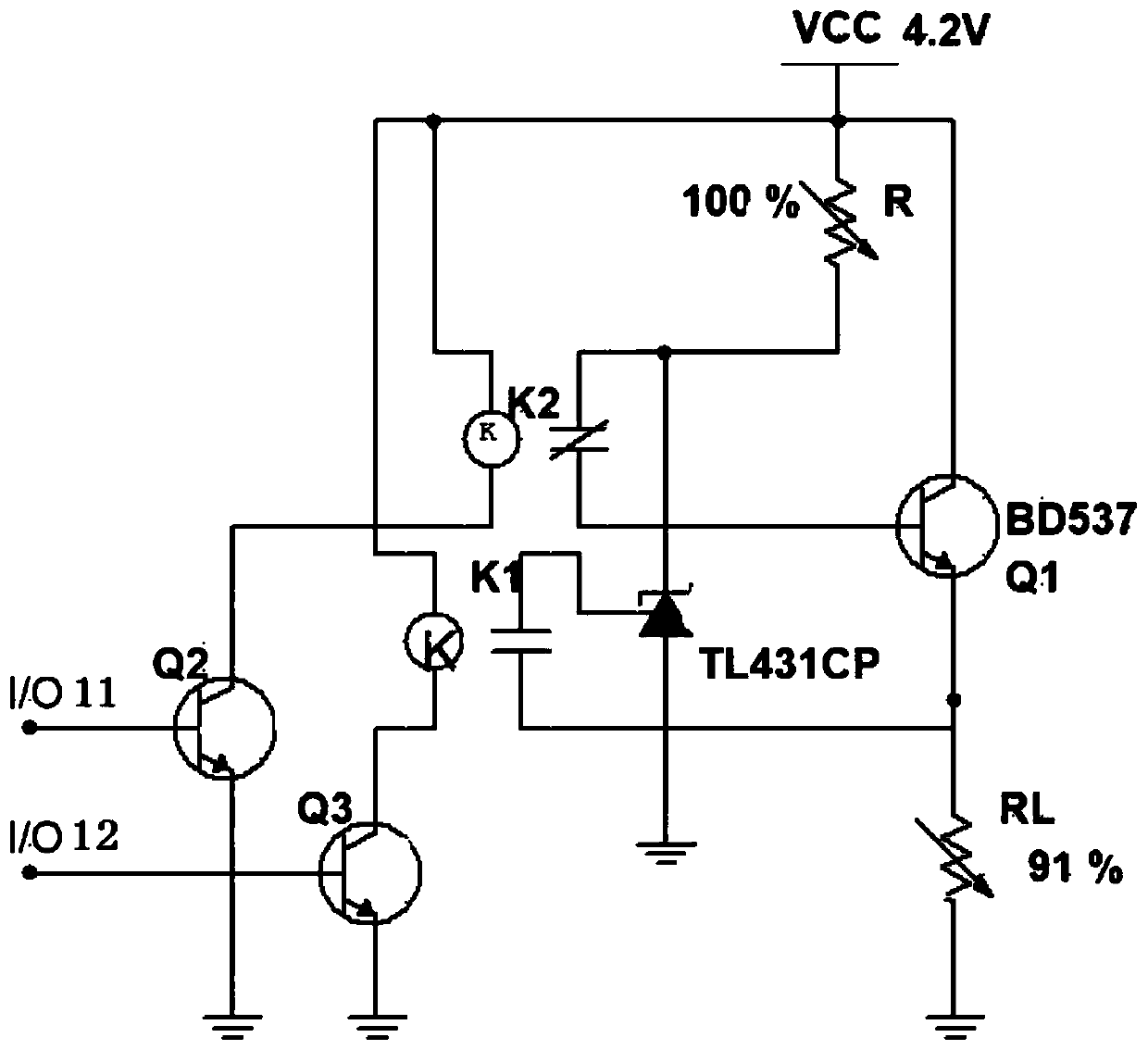

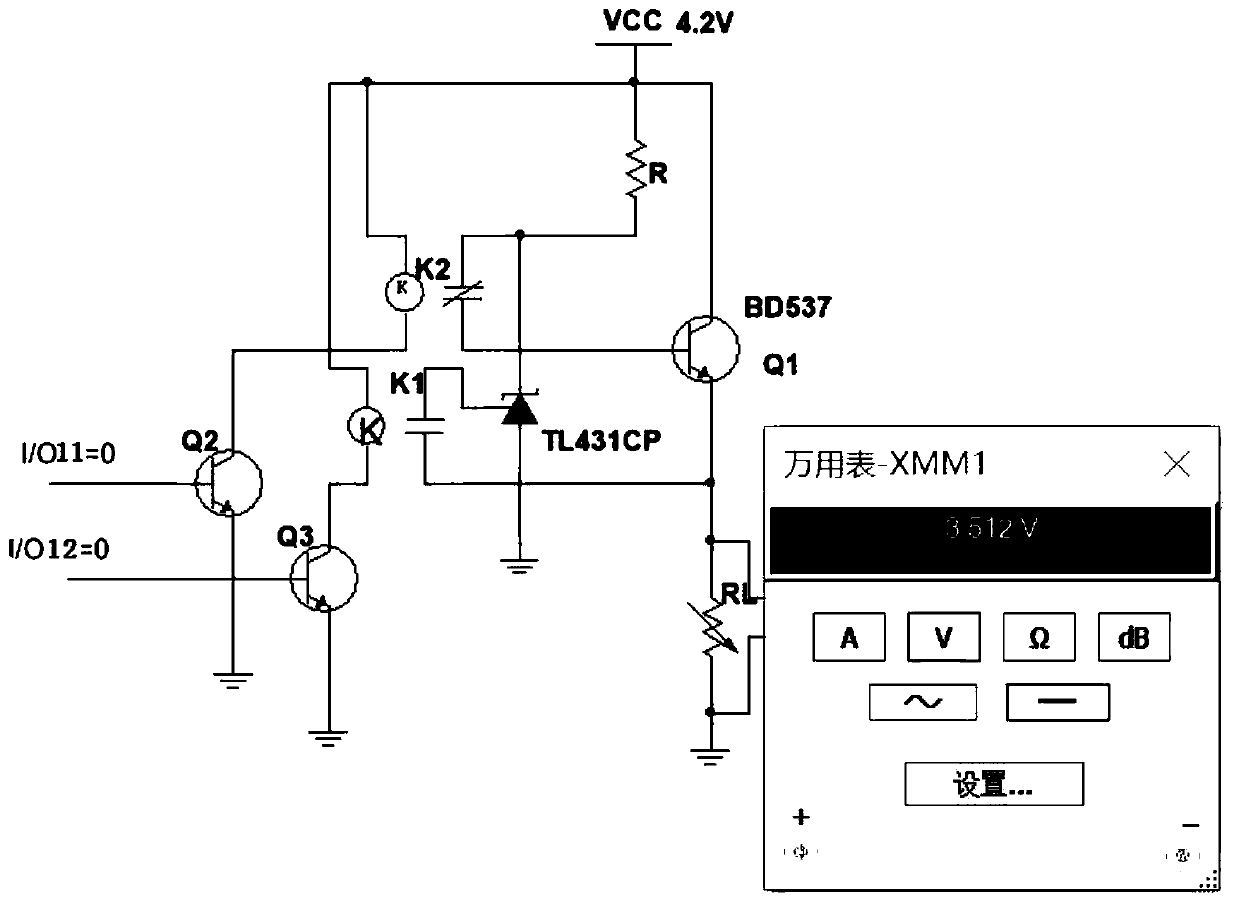

[0043] Embodiment 1: as Figure 1-5 As shown, a heating non-combustion electronic cigarette constant temperature control circuit includes a power supply 10, a start / sensing control module 11, a control module 12, a driving module 13, a prompt module 14, and a heating sheet 15;

[0044] The start / sensing control module 11 is used to control whether the power supply 10 supplies power to the entire control circuit;

[0045] The control module 12 is used to control the selection of the high-voltage constant-voltage source module 1301 and the low-voltage constant-voltage source module 1302 in the drive module 13, and prompts the selection of the modules through the prompt module 14;

[0046] The driving module 13 is used to provide a constant high voltage or low voltage to the heating plate 15 to drive and heat it, so as to realize the temperature rise of the heating plate 15;

[0047] The prompting module 14 is used to prompt the control module 12 to select the high voltage const...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com