Hydrotalcite like compound-kaolin composite material and preparation method thereof

A composite material, kaolin technology, applied in chemical instruments and methods, silicon compounds, inorganic chemistry, etc., can solve the problems of poor orientation, easy to fall off, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

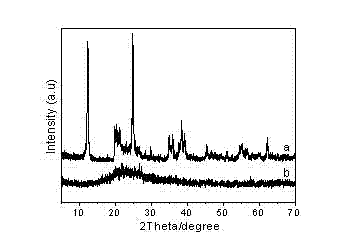

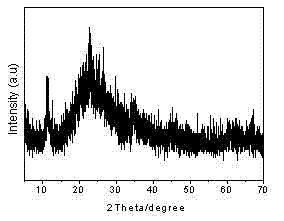

[0039] (1) Pretreatment of kaolin matrix: Kaolin raw powder was roasted in a muffle furnace at a heating rate of 1 °C / min to 830 °C for 2 h. XRD characterization results of samples before and after treatment were shown in figure 2 , figure 2 (a) shows the XRD pattern of raw kaolin powder; (b) shows the XRD pattern of pretreated kaolin powder.

[0040] (2) Weigh 1.017 g MgCl 2 ·6H 2 O and 3.003 g of urea were dissolved in 20 g of deionized water, 1 g of pretreated kaolin was added, stirred for 30 min, and placed in a stainless steel autogenous pressure crystallization kettle with polytetrafluoroethylene lining, and crystallized at 80 °C for 1 day. After the reaction, wash with deionized water for 3-5 times, filter, and dry in an oven at 80°C.

[0041] In the hydrotalcite-like kaolin composite material prepared in this example, the XRD and SEM characterization results of the hydrotalcite-like flakes are as follows Figure 3(a) , Figure 3 (b) shown.

Embodiment 2

[0043] (1) Pretreat the kaolin matrix according to the method used in Example 1.

[0044] (2) Weigh 1.017 g MgCl 2 ·6H 2 O and 1.802 g of urea were dissolved in 20 g of deionized water, 1 g of pretreated kaolin was added, stirred for 15 min, crystallized at 70 °C for 7 days, washed with deionized water after the reaction, filtered, and dried at 80 °C.

[0045] In the hydrotalcite-like kaolin composite material prepared in this example, the XRD and SEM characterization results of the hydrotalcite-like flakes are as follows Figure 4(a) , Figure 4 (b) shown.

Embodiment 3

[0047] (1) Pretreat the kaolin matrix according to the method used in Example 1.

[0048] (2) Weigh 0.509 g MgCl 2 ·6H 2 O and 0.903 g of urea were dissolved in 20 g of deionized water, 1 g of pretreated kaolin was added, stirred for 30 min, crystallized at 100 °C for 16 h, washed with deionized water and filtered, and dried at 100 °C.

[0049] In the hydrotalcite-like kaolin composite material prepared in this example, the XRD and SEM characterization results of the hydrotalcite-like flakes are as follows Figure 5(a) , as shown in Figure 5(b).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com